trebuie să fii logat

Category

Fotografiile au doar scop informativ. Vizualizați specificațiile produsului

please use latin characters

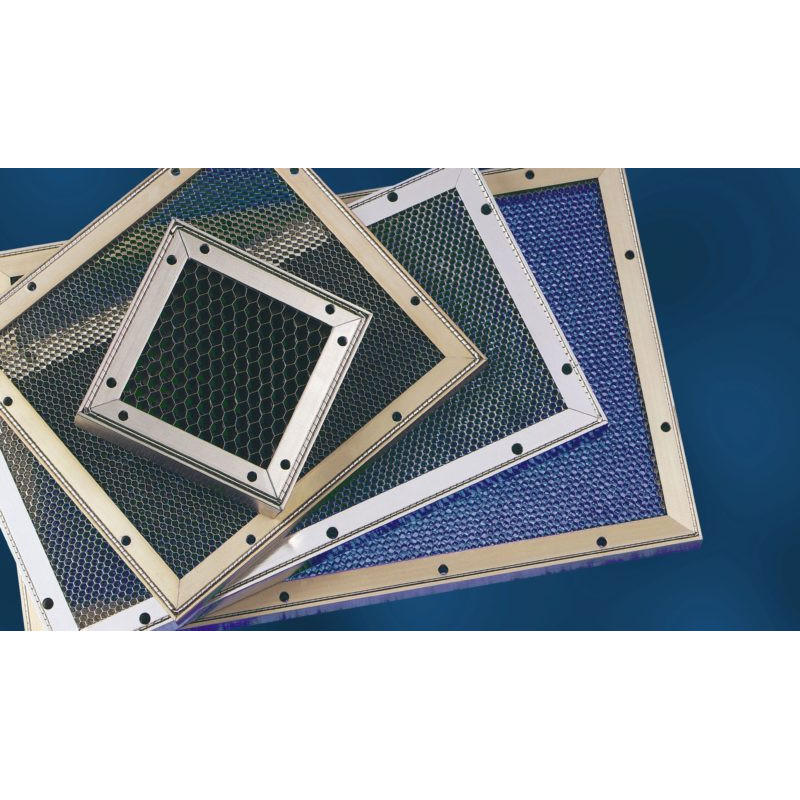

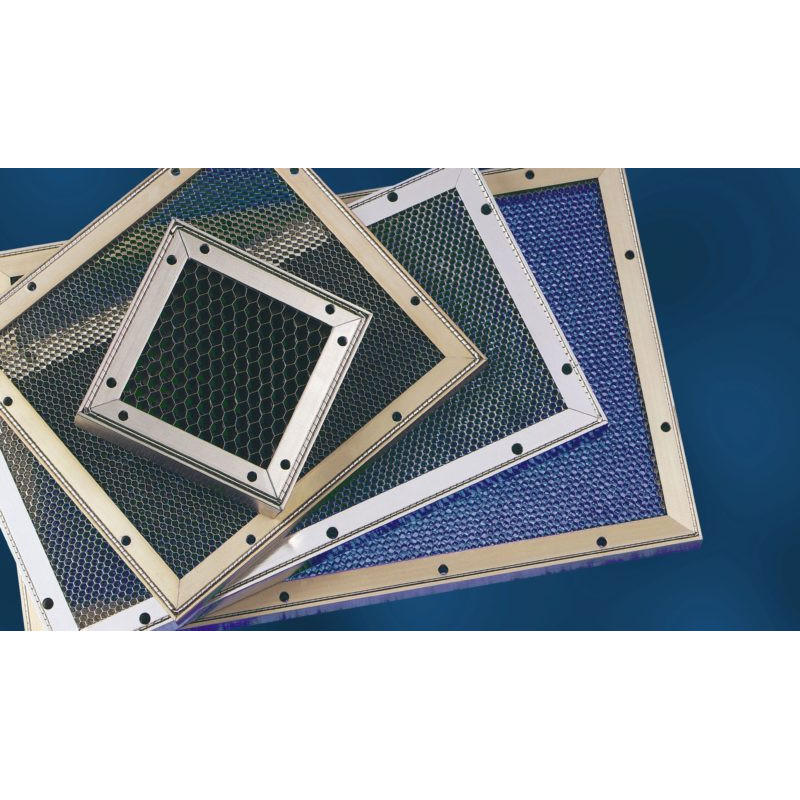

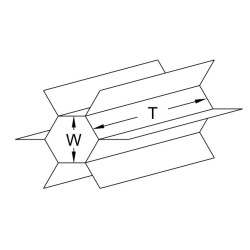

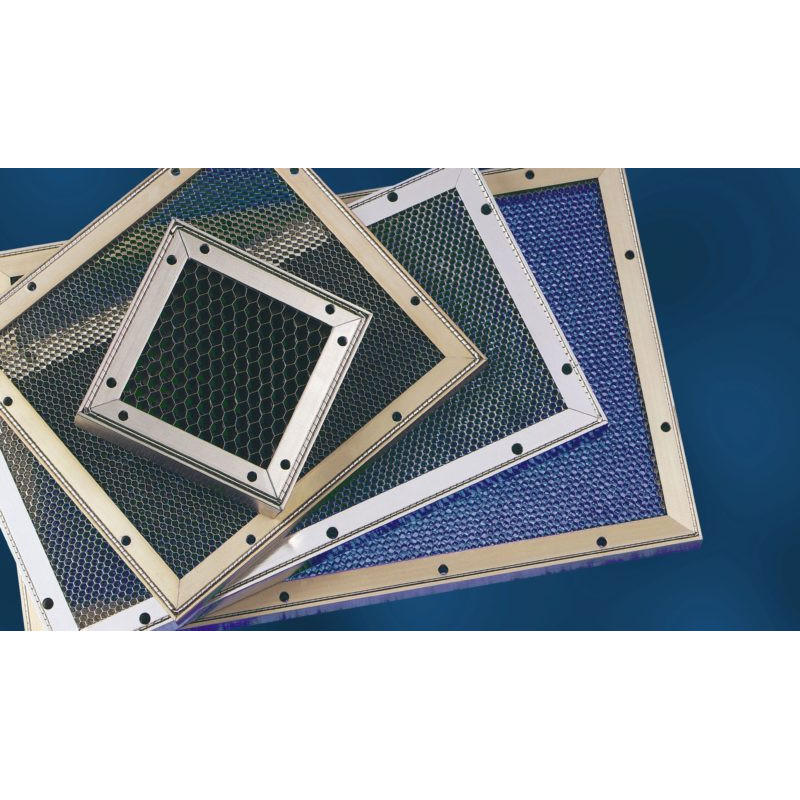

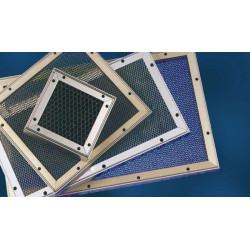

Designed to provide consistent and reliably high levels of shielding while allowing cooling air to penetrate an electrical equipment. SPIRA’S PATENTED PROCESS All Spira-Cell Air Vent Filters include our patented “blending” process of the aluminum honeycomb panel that provides high and reliable levels of shielding. Our filters also include the use of epoxy which mechanically bonds the honeycomb panel to the frame and the use of our patented spiral EMI gasket, which ensures an excellent, long-lasting EM bond between the panel and the frame.

Sunteți interesat de acest produs? Aveți nevoie de informații suplimentare sau de prețuri individuale?

trebuie să fii logat

Designed to provide consistent and reliably high levels of shielding while allowing cooling air to penetrate an electrical equipment. SPIRA’S PATENTED PROCESS All Spira-Cell Air Vent Filters include our patented “blending” process of the aluminum honeycomb panel that provides high and reliable levels of shielding. Our filters also include the use of epoxy which mechanically bonds the honeycomb panel to the frame and the use of our patented spiral EMI gasket, which ensures an excellent, long-lasting EM bond between the panel and the frame.

Aprecierea ta pentru recenzie nu a putut fi trimisa

Reclama un comentariu

Raport trimis

Reclamatia tau nu a putut fi trimisa

Scrie-ti recenzia

Recenzia a fost trimisa

Recenzia ta nu a putut fi trimisa