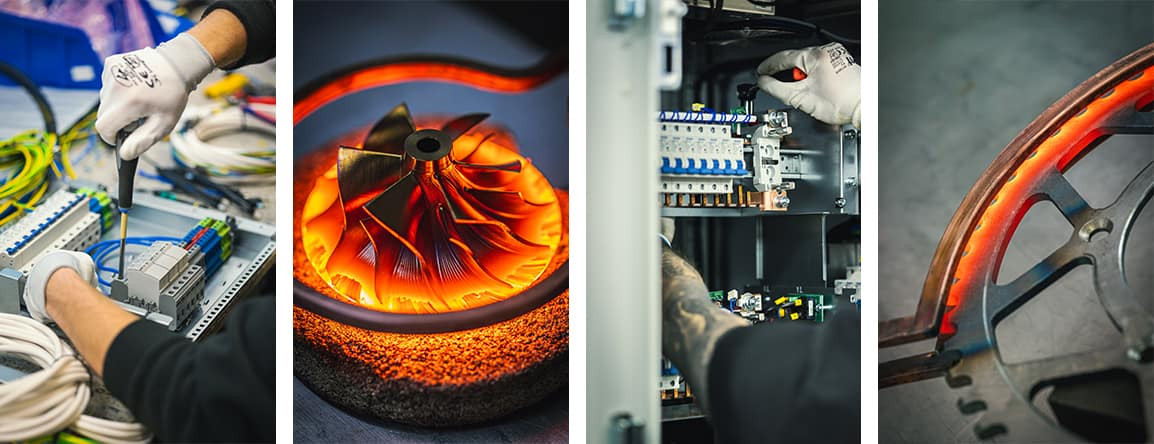

Articolul prezintă rolul esențial al energoelectronicii în industria și energia modernă, subliniind importanța sa în creșterea eficienței energetice, integrarea surselor regenerabile și sprijinirea tranziției către dezvoltare durabilă. Sunt analizate principalele aplicații, beneficii și tehnologii inovatoare care modelează viitorul infrastructurii energetice și al proceselor industriale.

Componente pentru electronică de putere, automatizări, electronice, electrice.

Categorii de produse

Vizualizați toate categoriileArticole

-

Aplicarea traductorilor LEM în automatizare și electronică de putereRead more

Traductoarele de curent LEM – măsurători precise în automatizare și electronică de putere. Aflați cum funcționează, tipurile lor, aplicațiile în sisteme DC și AC și sfaturi practice pentru instalare. Descoperiți avantajele preciziei ridicate, fiabilității și rezistenței la interferențe în medii industriale.

-

Redresoare în punte – principiul de funcționare și aplicații industrialeRead more

Articolul descrie redresoarele în punte – componente care transformă curentul alternativ (AC) în curent continuu (DC). Sunt explicate construcția lor, principiul de funcționare, tipurile și aplicațiile în electronică și industrie, subliniind importanța alegerii parametrilor corespunzători, filtrării și răcirii pentru asigurarea unei tensiuni stabile și a fiabilității sistemului.