Category

Фотографии предназначены только для информационных целей. Посмотреть спецификацию продукта

please use latin characters

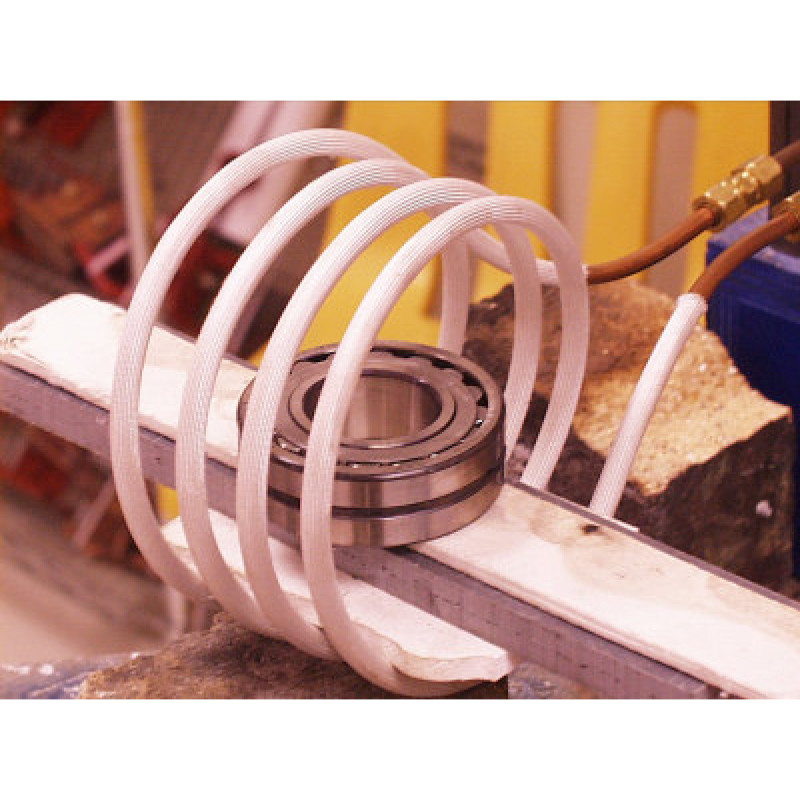

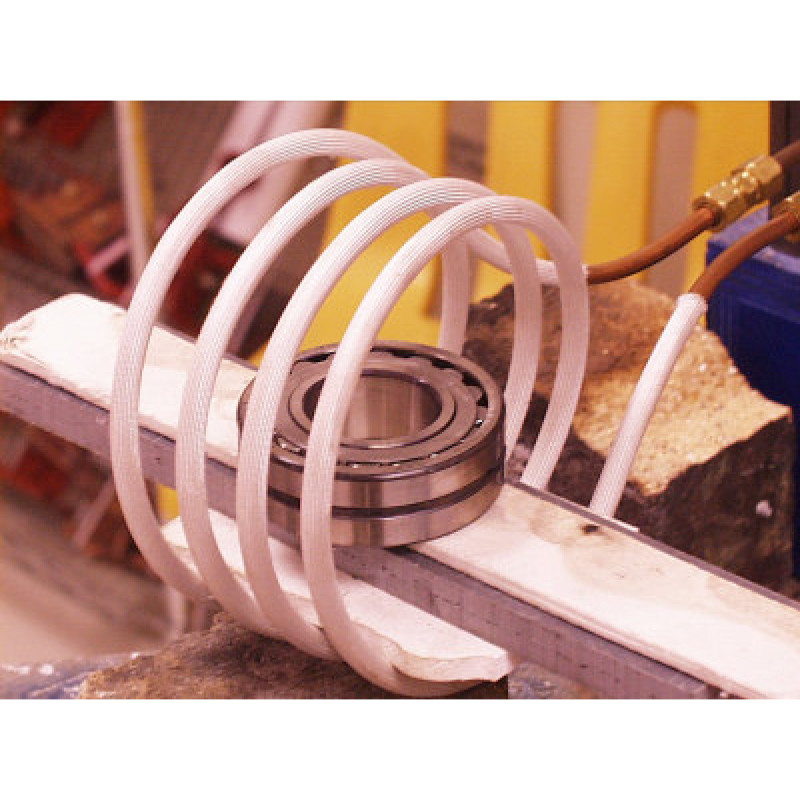

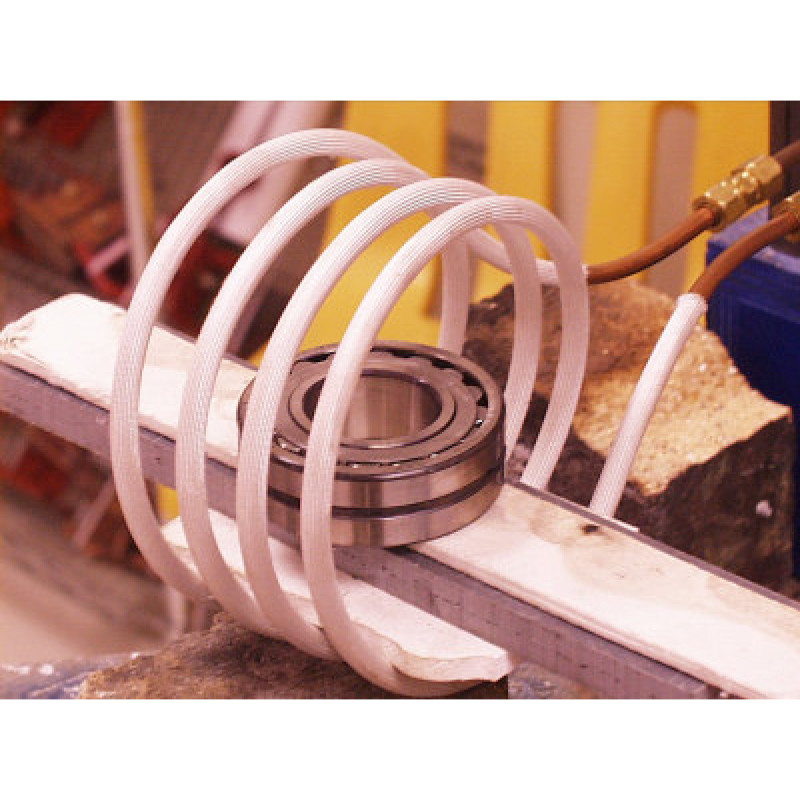

Objective: To heat a roller bearing assembly for a shrink fitting application.

Frequency: 180 kHz

Material: Steel bearings, diameters 1” to 3.5” (25.4 to 89mm)

Temperature: 300 ºF (150 ºC)

A multi-turn helical coil is used to generate the required heat pattern. The bearing is placed inside the induction-heating coil, its axis perpendicular to the axis of the coil to deliver uniform heat to the various size rings of the bearing. This ensures proper growth of the bearing assembly for subsequent shrinking on the steel shafts. (A full range of bearing sizes can be heated with a single coil design.) Temperature-indicating paints verify temperature uniformity and time needed to reach temperature. The bearing assemblies heat well and reach 300- 350ºF (150-175°C) in 30-60 seconds. Once heated, the bearings are easily shrunk onto the shafts without the use of external force.

A multi-turn helical coil delivers uniform heat to the entire range of the bearing sizes in the transverse mode. Use of this singlephase power supply greatly simplifies installation and promotes portability: the induction system can be placed on a cart and moved to the manufacturing areas requiring the heat for shrink-fitting.

Вы заинтересованы в этом продукте? Вам нужна дополнительная информация или индивидуальные расценки?

Вы должны быть зарегистрированы

Objective: To heat a roller bearing assembly for a shrink fitting application.

Frequency: 180 kHz

Material: Steel bearings, diameters 1” to 3.5” (25.4 to 89mm)

Temperature: 300 ºF (150 ºC)

A multi-turn helical coil is used to generate the required heat pattern. The bearing is placed inside the induction-heating coil, its axis perpendicular to the axis of the coil to deliver uniform heat to the various size rings of the bearing. This ensures proper growth of the bearing assembly for subsequent shrinking on the steel shafts. (A full range of bearing sizes can be heated with a single coil design.) Temperature-indicating paints verify temperature uniformity and time needed to reach temperature. The bearing assemblies heat well and reach 300- 350ºF (150-175°C) in 30-60 seconds. Once heated, the bearings are easily shrunk onto the shafts without the use of external force.

A multi-turn helical coil delivers uniform heat to the entire range of the bearing sizes in the transverse mode. Use of this singlephase power supply greatly simplifies installation and promotes portability: the induction system can be placed on a cart and moved to the manufacturing areas requiring the heat for shrink-fitting.

Не удаётся отправить вашу оценку отзыва

Пожаловаться на комментарий

Жалоба отправлена

Не удаётся отправить вашу жалобу

Оставьте свой отзыв

Отзыв отправлен

Не удаётся отправить отзыв