Category

Фотографии предназначены только для информационных целей. Посмотреть спецификацию продукта

please use latin characters

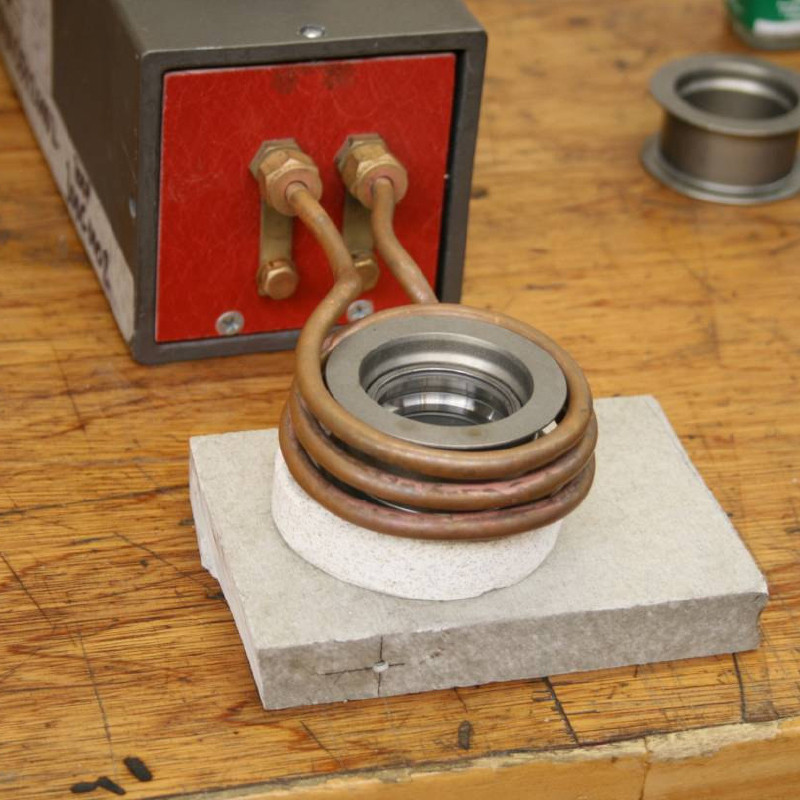

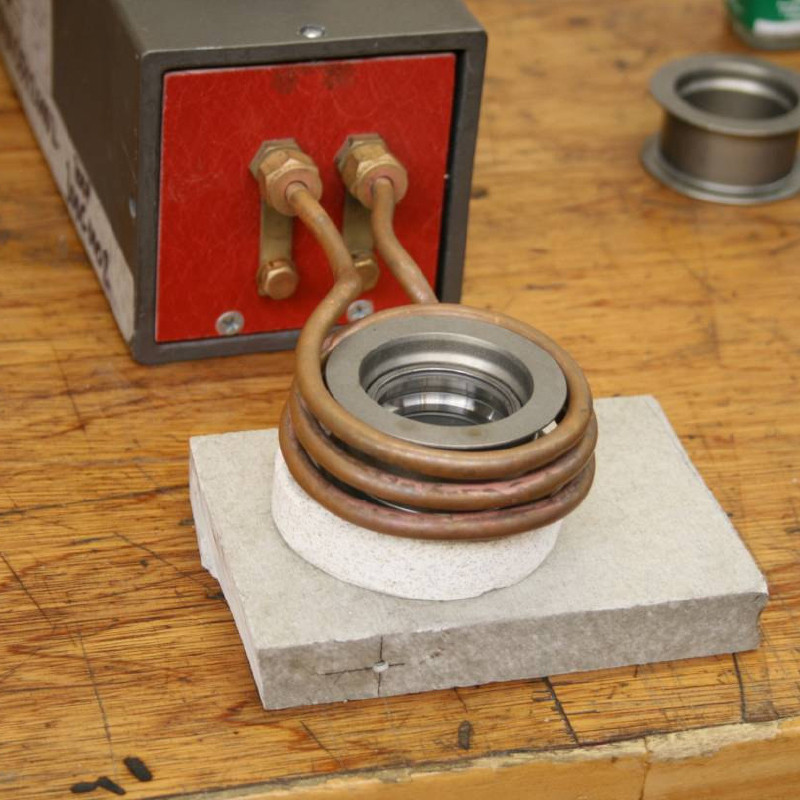

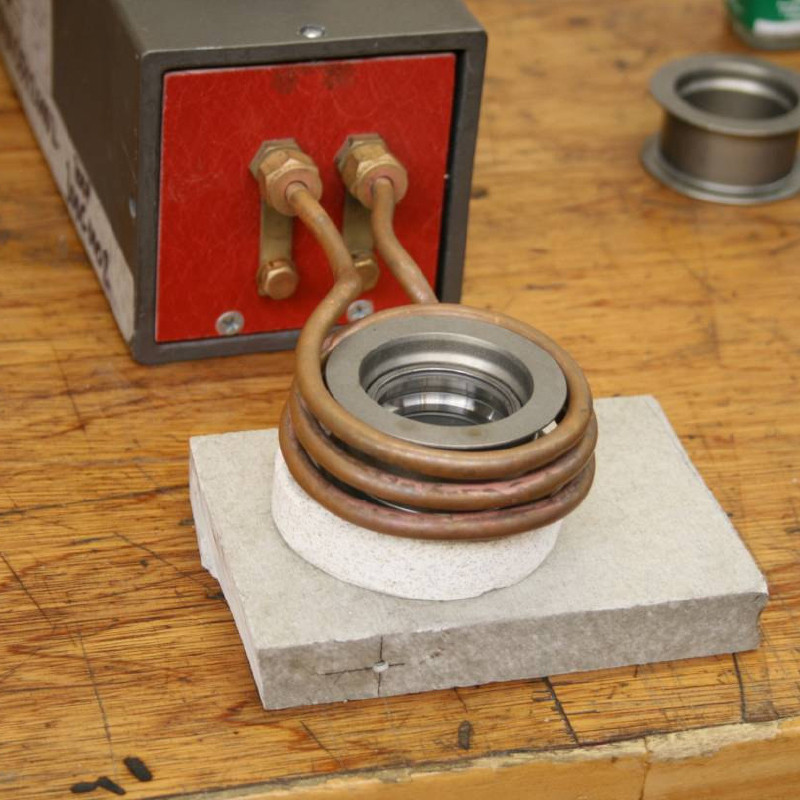

Objective: To heat aluminum pulley for insertion of an inner bearing for the automotive industry.

Frequency: 283 kHz

Material: Aluminum pulley 2.3” (60mm) OD x 1.6” (40mm) ID x 1” (27mm) high and inner bearing 0.7” (17.8mm) high x 1.6” (40mm) dia.

Temperature: 464 °F (240 °C)

A three turn helical coil is used to heat the aluminum pulley. The pulley is heated to 464 ºF (240 ºC) in 20 seconds to expand the inner diameter and then the inner bearing is inserted to form the completed part.

Вы заинтересованы в этом продукте? Вам нужна дополнительная информация или индивидуальные расценки?

Вы должны быть зарегистрированы

Objective: To heat aluminum pulley for insertion of an inner bearing for the automotive industry.

Frequency: 283 kHz

Material: Aluminum pulley 2.3” (60mm) OD x 1.6” (40mm) ID x 1” (27mm) high and inner bearing 0.7” (17.8mm) high x 1.6” (40mm) dia.

Temperature: 464 °F (240 °C)

A three turn helical coil is used to heat the aluminum pulley. The pulley is heated to 464 ºF (240 ºC) in 20 seconds to expand the inner diameter and then the inner bearing is inserted to form the completed part.

Не удаётся отправить вашу оценку отзыва

Пожаловаться на комментарий

Жалоба отправлена

Не удаётся отправить вашу жалобу

Оставьте свой отзыв

Отзыв отправлен

Не удаётся отправить отзыв