-

вернутьсяX

-

Компоненты

-

-

Category

-

Полупроводниковые приборы

- Диоды

- Тиристоры

-

Электро-изолированные модули

- Электроизолированные модули | ВИШАЙ (ИК)

- Электроизолированные модули | INFINEON (EUPEC)

- Электроизолированные модули | Семикрон

- Электроизолированные модули | POWEREX

- Электроизолированные модули | IXYS

- Электроизолированные модули | ПОЗЕЙКО

- Электроизолированные модули | ABB

- Электроизолированные модули | TECHSEM

- Перейти в подкатегорию

- Выпрямительные мостики

-

Транзисторы

- Транзисторы | GeneSiC

- Модули SiC MOSFET | Mitsubishi

- Модули SiC MOSFET | STARPOWER

- Модули ABB SiC MOSFET

- Модули IGBT | МИЦУБИСИ

- Транзисторные модули | MITSUBISHI

- Модули MOSFET | МИЦУБИСИ

- Транзисторные модули | ABB

- Модули IGBT | POWEREX

- Модули IGBT | INFINEON (EUPEC)

- Полупроводниковые элементы из карбида кремния (SiC)

- Перейти в подкатегорию

- Драйвера

- Блоки мощности

- Перейти в подкатегорию

- Электрические преобразователи

-

Пассивные компоненты (конденсаторы, резисторы, предохранители, фильтры)

- Резисторы

-

Предохранители

- Миниатюрные предохранители для электронных плат серии ABC и AGC

- Быстрые трубчатые предохранители

- Медленные вставки с характеристиками GL/GG и AM

- Ультрабыстрые плавкие вставки

- Быстрые предохранители английский и американский стандарт

- Быстрые предохранители европейский стандарт

- Тяговые предохранители

- Высоковольтные предохранительные вставки

- Перейти в подкатегорию

-

Конденсаторы

- Конденсаторы для электромоторов

- Электролитические конденсаторы

- Конденсаторы типа snubbers

- Конденсаторы мощности

- Конденсаторы для цепей DC

- Конденсаторы для компенсации пассивной мощности

- Высоковольтные конденсаторы

- Конденсаторы большой мощности для индукционного нагрева

- Импульсные конденсаторы

- Конденсаторы звена постоянного тока

- Конденсаторы для цепей переменного/постоянного тока

- Перейти в подкатегорию

- Противопомеховые фильтры

- Ионисторы

-

Защита от перенапряжения

- Ограничители перенапряжения для приложений RF

- Ограничители перенапряжения для систем технического зрения

- Ограничители перенапряжения для линий электропередач

- Ограничители перенапряжения для светодиодов

- Ограничители перенапряжения для фотовольтаики

- Ограничители перенапряжения для систем взвешивания

- Ограничители перенапряжения для Fieldbus

- Перейти в подкатегорию

- Перейти в подкатегорию

-

Реле и контакторы

- Теория реле и контакторы

- Полупроводниковые реле AC 3-фазные

- Полупроводниковые реле DC

- Контроллеры, системы управления и аксессуары

- Системы плавного пуска и реверсивные контакторы

- Электро-механические реле

- Контакторы

- Оборотные переключатели

-

Полупроводниковые реле AC 1-фазные

- РЕЛЕ AC 1-ФАЗНЫЕ СЕРИИ 1 D2425 | D2450

- Однофазное реле AC серии CWA и CWD

- Однофазное реле AC серии CMRA и CMRD

- Однофазное реле AC серии PS

- Реле AC двойное и четверное серии D24 D, TD24 Q, H12D48 D

- Однофазные твердотельные реле серии gn

- Однофазные полупроводниковые реле переменного тока серии ckr

- Однофазные реле переменного тока ERDA И ERAA SERIES для DIN-рейки

- Однофазные реле переменного тока на ток 150А

- Двойные твердотельные реле, интегрированные с радиатором для DIN-рейки

- Перейти в подкатегорию

- Полупроводниковые реле AC 1-фазные для печати

- Интерфейсные реле

- Перейти в подкатегорию

- Индукционные компоненты

- Радиаторы, варисторы, термическая защита

- Вентиляторы

- Кондиционеры, оборудование для шкафов, охладители

-

Аккумуляторы, зарядные устройства, буферные источники питания и инверторы

- Аккумуляторы, зарядные устройства - теоретическое описание

- Модульные литий-ионные аккумуляторы, пользовательские батареи, Система управления батареями (BMS)

- Аккумуляторы

- Зарядные устройства и аксессуары

- Резервный источник питания ИБП и буферные источники питания

- Преобразователи и аксессуары для фотовольтаики

- Хранилище энергии

- Топливные элементы

- Литий-ионные аккумуляторы

- Перейти в подкатегорию

-

Автоматика

- Futaba Drone Parts

- Концевые выключатели, Микровыключатели

- Датчики Преобразователи

- Пирометры

- Счетчики, Реле времени, Панельные измерительные приборы

- Промышленные защитные устройства

- Световые и звуковые сигнальные установки

- Термокамеры, Тепловизоры

- LED-экраны

- Управляющая аппаратура

-

Регистраторы

- Регистраторы температуры с записью на ленту и с цифровым показателем - AL3000ym - AL3000

- Микропроцесорные регистраторы с экраном LCD серия KR2000

- Регистратор KR5000

- Измеритель с функцией регистрации влажности и температуры HN-CH

- Эксплуатационные материалы для регистраторов

- Компактный графический регистратор 71VR1

- Регистратор KR 3000

- Регистратор PC серии R1M

- Регистратор PC серии R2M

- Регистратор PC, USB, 12 изолированных входов – RZMS

- Регистратор PC, USB, 12 изолированных входов – RZUS

- Перейти в подкатегорию

- Перейти в подкатегорию

-

Провода, литцендрат, гофрированные рукава, гибкие соединения

- Провода

- Многожильные провода (Lica)

-

Кабели и провода для специальных применений

- Удлинительные и компенсационные провода

- Провода для термопар

- Присоединительные провода для датчиков PT

- Многожильные провода темп. от -60C до +1400C

- Провода среднего напряжения

- Провода зажигания

- Нагревательные провода

- Одножильные провода темп. от -60C до +450C

- Железнодородные провода

- Нагревательные провода в Ex

- Перейти в подкатегорию

- Оболочки

-

Плетеные кабели

- Плоские плетеные кабели

- Круглые плетеные кабели

- Очень гибкие плетеные кабели - плоские

- Очень гибкие плетеные кабели - круглые

- Медные цилиндрические плетеные кабели

- Медные цилиндрические плетеные кабели и кожуха

- Гибкие заземляющие ленты

- Цилиндрические плетеные провода из луженой и нержавеющей стали

- Медные изолированные плетеные провода PCV - температура до 85 градусов C

- Плоские алюминиевые плетеные провода

- Соединительный набор - плетеные провода и трубки

- Перейти в подкатегорию

- Аксессуары для тяги

- Кабельные наконечники

- Изолированные эластичные шины

- Многослойные гибкие шины

- Системы прокладки кабеля (PESZLE)

- Трубы

- Перейти в подкатегорию

- Просмотреть все категории

-

Полупроводниковые приборы

-

-

- Поставщики

-

Программы

- Energy bank

- Автоматика HVAC

- Горное дело, металлургия и литейное дело

- Двигатели и трансформаторы

- Измерение и регулирование температуры

- Измерение и регулирование температуры

- Индукционный нагрев

- Индустриальная автоматизация

- Источники питания (ИБП) и выпрямительные системы

- Компоненты для потенциально взрывоопасных сред (EX)

- Машины для сушки и обработки древесины

- Машины для термоформования пластмасс

- Оборудование для распределительных, контрольных и телекоммуникационных шкафов

- Печать

- Приводы переменного и постоянного тока (инверторы)

- Промышленная автоматика

- Промышленные защитные устройства

- Сварочные аппараты и сварочные аппараты

- Станки с ЧПУ

- Трамвай и ж / д тяга

-

Монтаж

-

-

Индукторы

-

-

Индукционные устройства

-

-

https://www.dacpol.eu/pl/naprawy-i-modernizacje

-

-

Услуга

-

- Контакт

- Zobacz wszystkie kategorie

Precast Concrete Industry – Application Series: 2 of 5

Precast Concrete Industry – Application Series: 2 of 5

Gravel Pits: Confined Space – Trapped Key Interlock Safety Solutions

4.8 million confined space incidents a year are logged with OSHA

Τhe storage of aggregate for various usage can lead to the potential risk to personnel involving engulfment within hoppers (confined space) and loss of materials due to incorrect materials loading. Protecting workers from confined space hazards that can occur during maintenance, cleaning, filling, and unloading of hoppers is critical within a gravel pit.

In 2020, according to the MAYDAY-FORMATION website, there were 10 fatal accidents and 20 serious accidents in France related to confined spaces

Interlocking access doors/gates around conveyor systems and hoppers will ensure that entry can only be gained after the power has been isolated and residual energy has ceased. Understanding the access points, partial or full body, will help determine the best interlocking solution to safely manage access to the hoppers and surrounding areas that could pose a confined space hazard.

60% of confined space fatalities are rescuers – Let’s change the statistics and enhance your safety!

Trapped key interlock safety solutions ensure a pre-determined sequence of operations each & every time. While LOTO provides a visual warning and identifies hazards, a TKI solution physically prevents a specific set of actions from being performed until previous action(s) have been fully completed!

Common trapped key interlock solution interlocking conveyor system with multiple access points and hopper doors to mitigate confined space hazards:

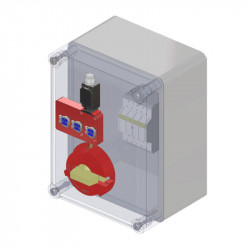

Step 1: Power Isolation MS Bolt Lock installed on main breaker for conveyor

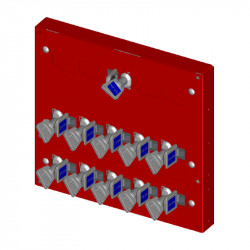

Step 2: Multiple Entry Points STI TMEC key exchange box for access to multiple hopper access doors

Step 3: Safe Access MS30LTC* access lock installed on hopper doors

Связанные продукты

Связанные посты

Now available – DC/DC converters from PREMIUM

Now available – DC/DC converters from PREMIUM

New release in DACPOL lighting for lathes – Kira covers

New release in DACPOL lighting for lathes – Kira covers

Оставить комментарий