Измерители расстояния

Категории

- Основа работы троссового преобразователя длины (расстояния), просмотр доступных типов

- Троссовый преобразователь длины (расстояния) PT1

- Троссовый преобразователь длины (расстояния) PT5

- Троссовый преобразователь длины (расстояния) PT8000

- Троссовый преобразователь длины (расстояния) PT9000

- Троссовый преобразователь длины (расстояния) PT9000EXT

- Троссовый преобразователь длины (расстояния) SP1

- Датчики расстояния линейные серии SM

- Датчики расстояния линейные серии SG

- Датчики линейные серии SR1

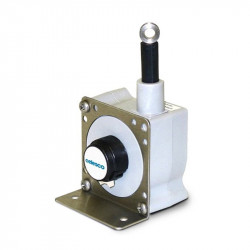

What is a cable length-measuring transducer?

Cable length measuring transducers, also called cable extension transducers or line distance transducers, allow measuring linear change in location and to follow by using track cable of a given object’s movement. Cable transducer is an electromechanical device from the automation sector, working based on a change in linear movement to the proportional to relocation electric signal, that is, a countable change is resistance or number of impulses. They have various ranges of distance, even from 100 mm to several dozens of meters.

Line distance transducer is composed of:

- measuring cable - often made of highly flexible steel sennit,

- drum powered by innerspring engine,

- precise spool,

- innerspring to tighten the spool,

- measuring sensor - multi turn potentiometer or incremental encoder.

How do cable extension transducers work?

Transducer of this type works based on a rolling mechanism, which guarantees stable forward tension strength of the cable. Clutch connects a multi turn potentiometer with a signal formatting electronics. There are also motorized cable transducers, mostly used for very high measurement ranges.

A way of functioning of cable relocation and reposition sensor is based on placing the end of the cable on a moving measured object, while the transducer has to be connected to a stable base. The movement of an object makes the spool move and the rotation reader transfers this activity as a proportional output signal, which later can be transferred to the control or display on a reader.

Types of transducers:

Transducers with a potentiometer or encoder sensors - in case of using the encoder (rotation incremental or code) the absolute output with Gray’s code are used or serial outputs in SSI/CANopen standard.

Transducers with resistance output (sensor is the potentiometer) - precise potentiometer provides absolute signal.

Pulse transducers (in case of an incremental encoder) and cable output transducers with voltage or current signal.

In which applications cable extension transducers can be beneficial?

- Assets of cable extension transducers:

- Measurements in hard to reach places,

- Simplicity of montage,

- Resilience to vibrations,

- Possibility of usage in harsh environments e.g. with high temperatures.

Applications of cable length measuring transducers:

- Cable length measuring transducers can be used in sectors like industrial automatics, medical technology, control of materials, building and vehicle safety, and control over hydraulics.

- Some of the most common applications are:

- Control of the extension of telescopic lift arms or lift trucks.

- Testing devices in automotive.

- Injection molding machines, printers, cutting machines, plane lifts.

- Medical and rehabilitation devices, X-ray devices.

- Control over relocation of pipe connections, measuring liquid’s level.