Category

Фотографии предназначены только для информационных целей. Посмотреть спецификацию продукта

please use latin characters

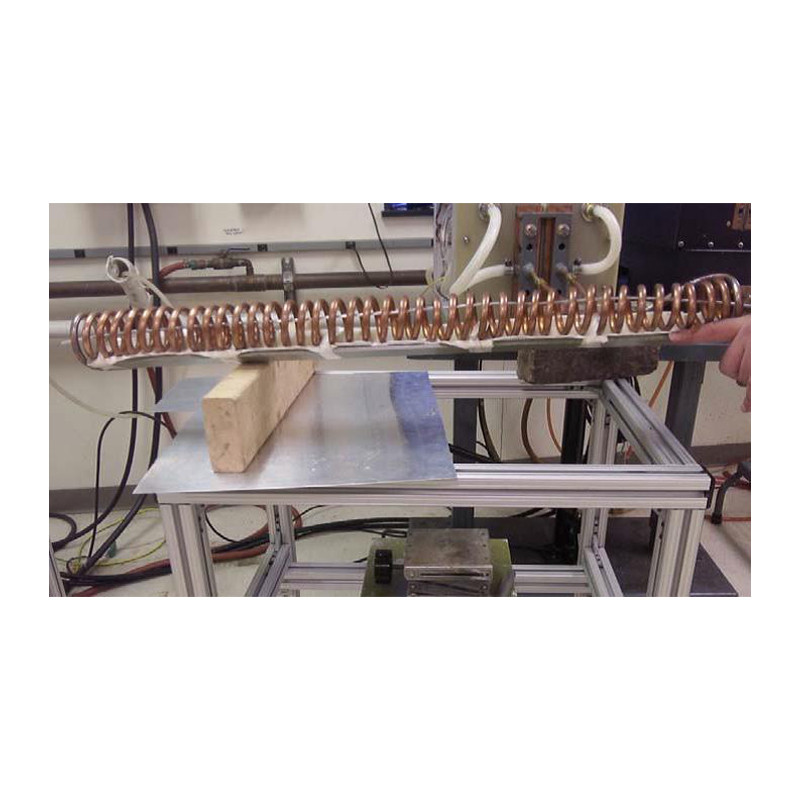

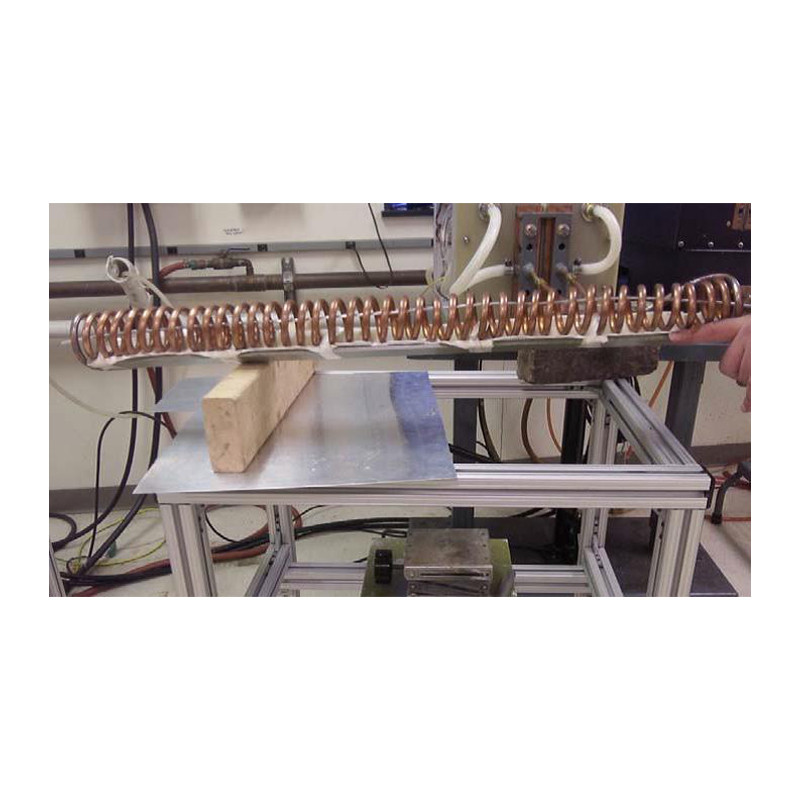

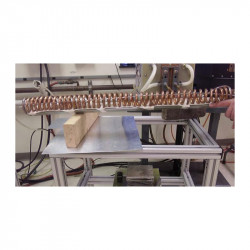

Objective: Heating the aluminum wire to achieve a temperature equal to that of the plastic coating applied to the wire

Material: Aluminum cable (diameter: 3.7 mm)

Temperature: 232 ºC

Frequency: 18 kHz

System: Ambrell EKOHEAT 50kW Induction heating system, 15-45 kHz with remote head, inductor consisting of 40 coils (length 0.8 m)

Process: It took 3 seconds to heat the wire to 232 ºC.

Results:

Вы заинтересованы в этом продукте? Вам нужна дополнительная информация или индивидуальные расценки?

Вы должны быть зарегистрированы

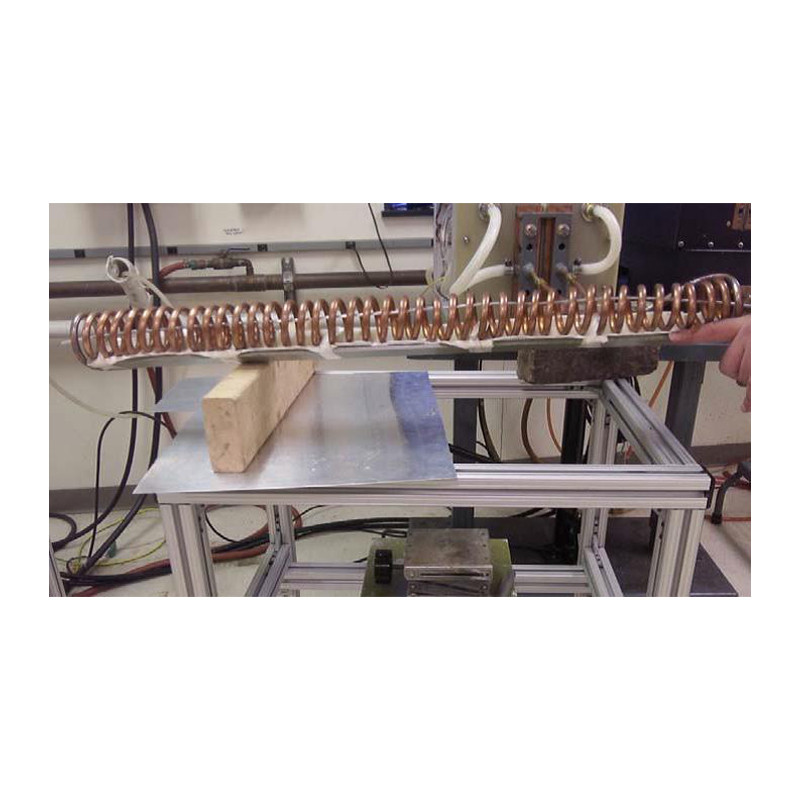

Objective: Heating the aluminum wire to achieve a temperature equal to that of the plastic coating applied to the wire

Material: Aluminum cable (diameter: 3.7 mm)

Temperature: 232 ºC

Frequency: 18 kHz

System: Ambrell EKOHEAT 50kW Induction heating system, 15-45 kHz with remote head, inductor consisting of 40 coils (length 0.8 m)

Process: It took 3 seconds to heat the wire to 232 ºC.

Results:

Не удаётся отправить вашу оценку отзыва

Пожаловаться на комментарий

Жалоба отправлена

Не удаётся отправить вашу жалобу

Оставьте свой отзыв

Отзыв отправлен

Не удаётся отправить отзыв