Морате бити пријављени да

Category

Фотографије су само у информативне сврхе. Погледајте спецификацију производа

please use latin characters

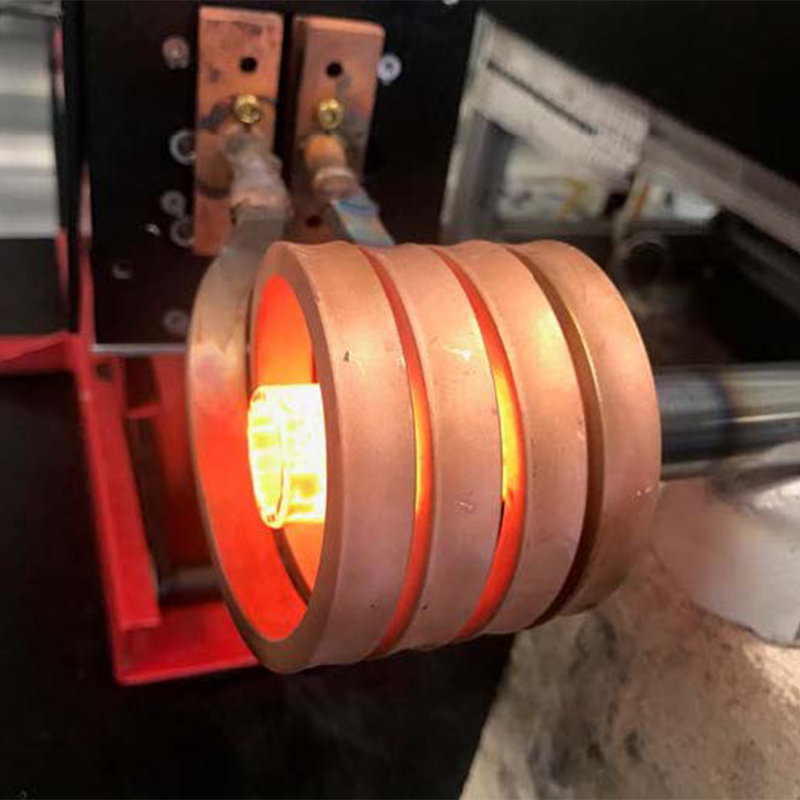

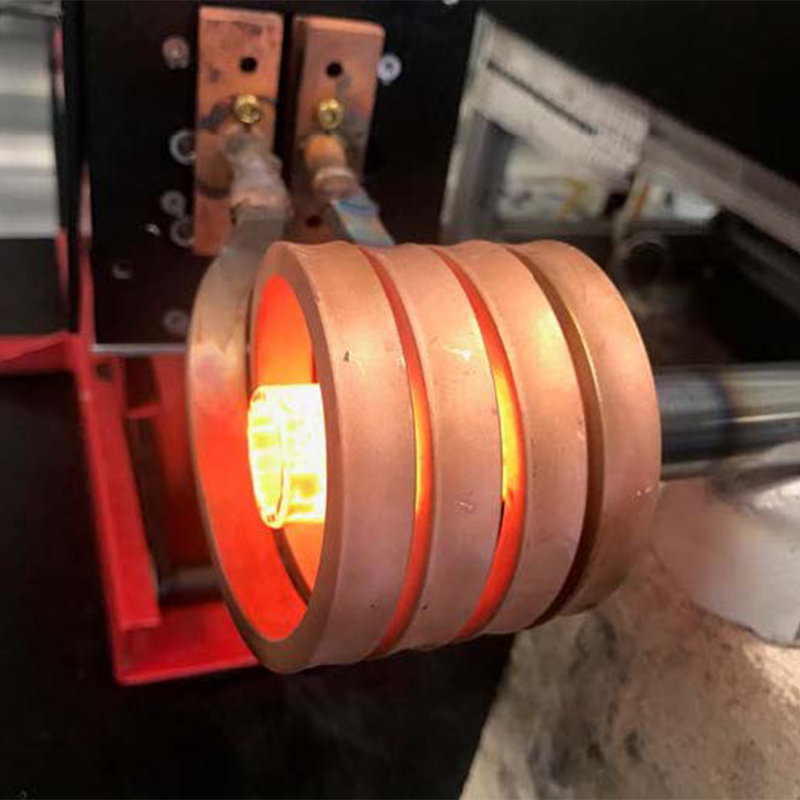

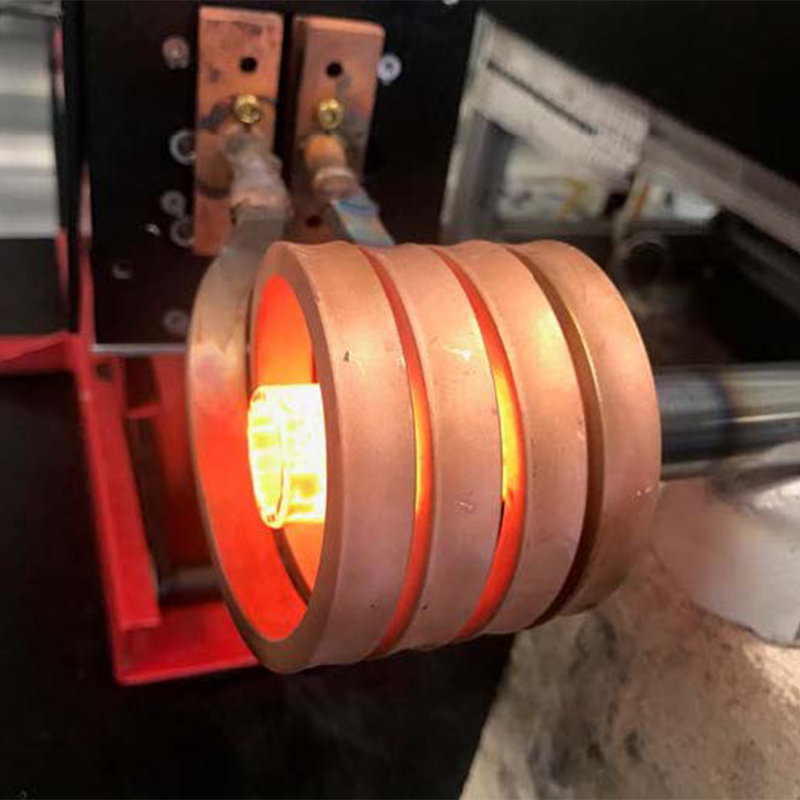

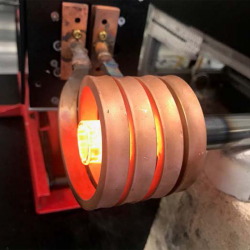

Objective: To heat steel tube ends for a flattening/bending applications; the end customer uses products in the manufacturing industry.

Frequency: 191 kHz

Material: Steel tubes

Temperature: 1600 ºF (871 ºC)

Process: First, temperature indicating paint was applied to the part, which dissolves when the part reaches the target temperature. It took less than 20 seconds to heat the provided smaller tube sample to 1600 °F (871 °C) and it took 40 seconds to heat the larger sample tube to temperature. The client was seeing heating times of at least two minutes with an oven, so this is a significant improvement.

Benefits:

Да ли вас занима овај производ? Да ли су вам потребне додатне информације или појединачне цене?

морате бити пријављени

Objective: To heat steel tube ends for a flattening/bending applications; the end customer uses products in the manufacturing industry.

Frequency: 191 kHz

Material: Steel tubes

Temperature: 1600 ºF (871 ºC)

Process: First, temperature indicating paint was applied to the part, which dissolves when the part reaches the target temperature. It took less than 20 seconds to heat the provided smaller tube sample to 1600 °F (871 °C) and it took 40 seconds to heat the larger sample tube to temperature. The client was seeing heating times of at least two minutes with an oven, so this is a significant improvement.

Benefits:

Vaša zahvalnost na komentar ne može biti registrovana

Prijavite nepristojan komentar

Prija nepristojnog komentara registrovana

Vaša prijava nepristojnog komentara ne može biti registrovana

Napišite vaš komentar

Komentar poslat

Vaš komentar ne može biti registrovan