Морате бити пријављени да

Category

Фотографије су само у информативне сврхе. Погледајте спецификацију производа

please use latin characters

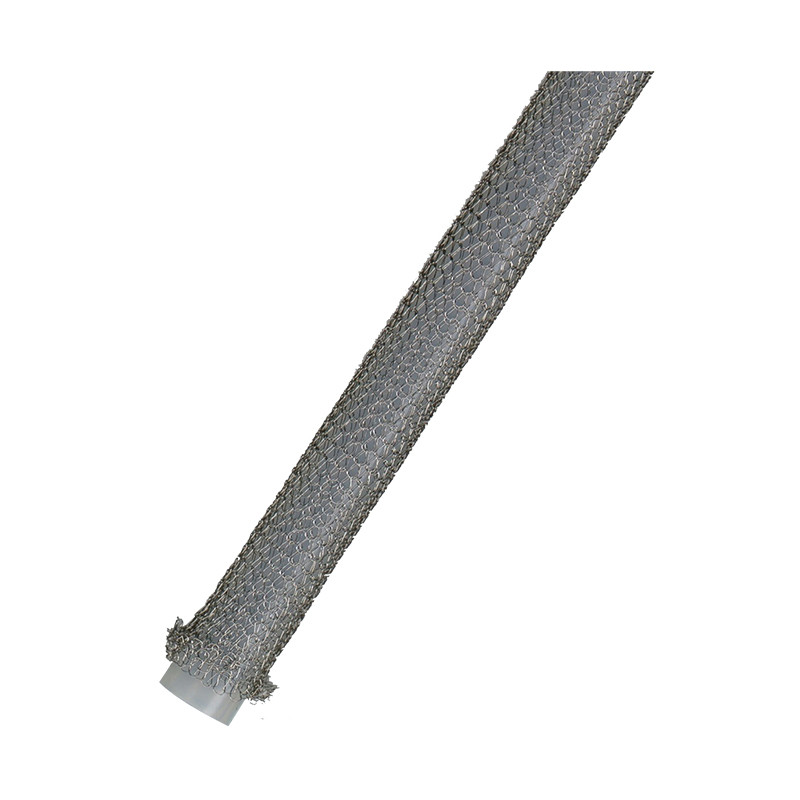

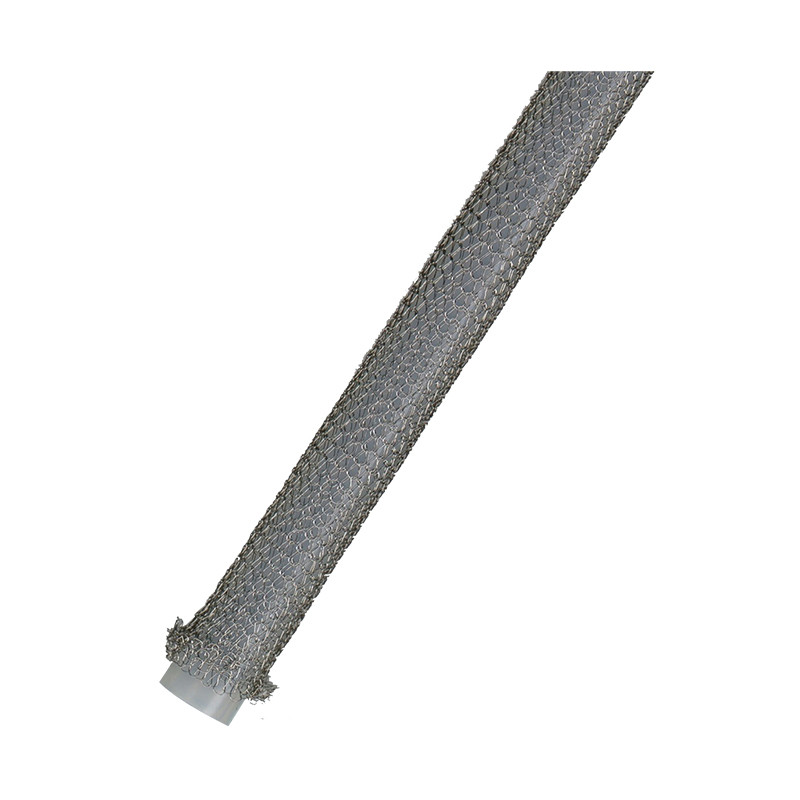

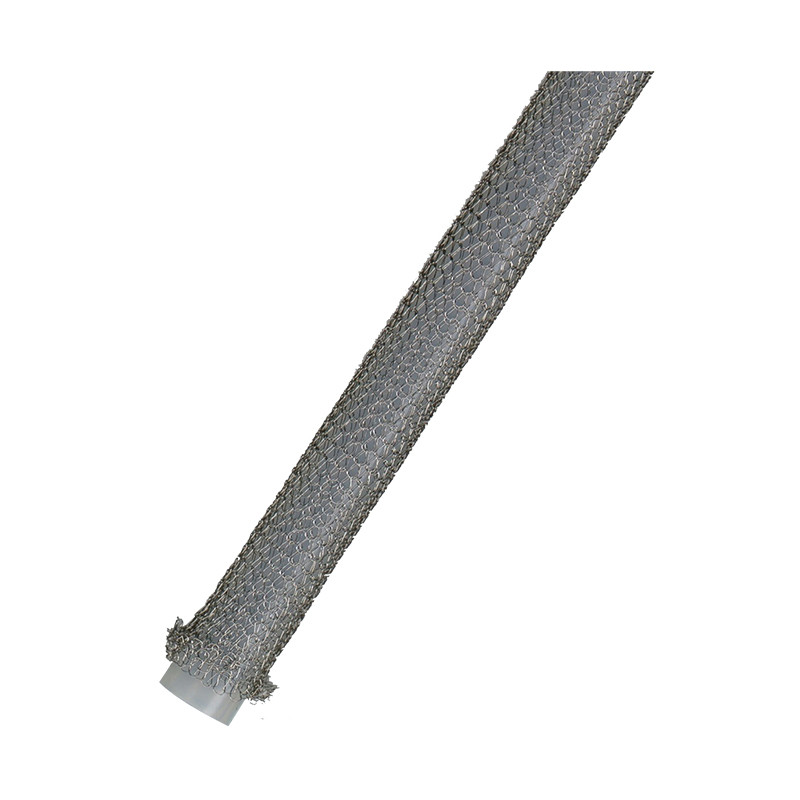

Elastomer core gasketsare made of a resilient rubber core, knitted over by layers of wire mesh (most common istwo layers). The knitted wire element provides EMI shielding effectiveness, while the elastomer core enables the gasket section to recover more quickly, following repeated compressions. Elastomer core gasketsare used where the application requires a conformable EMI seal and even where a dust protection is needed.

Available materials:

Complete the P/N with

2- letters core suffix ; the number of layers (2 is standard) ;

2- letters METAL SUFFIX.

And wire materials:

Mechanical tolerances

1,5-5 mm +0,3 -0,3 mm

5,5-12 mm +0,6 -0,6 mm

>12 mm +0,9 -0,9 mm

BE.048.159.ST.2-MO

double P section, 4.8x15.9 mm , 2 layers of Monel wire over Silicone Tube

Round

| P/N | Diameter [mm] |

|---|---|

TE.016 |

1.6 |

TE.024 |

2.4 |

TE.032 |

3.2 |

TE.048 |

4.8 |

TE.064 |

6.4 |

TE.080 |

8.0 |

TE.095 |

9.5 |

TE.111 |

11.1 |

TE.127 |

12.7 |

TE.159 |

15.9 |

TE.191 |

19.1 |

Rectangular

| P/N | Height [mm] |

Width [mm] |

|---|---|---|

RE.024.024 |

2.4 | 2.4 |

RE.024.048 |

2.4 | 4.8 |

RE.024.064 |

2.4 | 6.4 |

RE.032.032 |

3.2 | 3.2 |

RE.032.064 |

3.2 | 6.4 |

RE.032.080 |

3.2 | 8.0 |

RE.048.048 |

4.8 | 4.8 |

RE.048.080 |

4.8 | 8.0 |

RE.048.127 |

4.8 | 12.7 |

RE.064.064 |

6.4 | 6.4 |

RE.064.127 |

6.4 | 12.7 |

RE.080.127 |

8.0 | 12.7 |

RE.095.127 |

9.5 | 12.7 |

P section

| P/N | Height [mm] |

Width [mm] |

|---|---|---|

PE.032.095 |

3.2 | 9.5 |

PE.032.127 |

3.2 | 12.7 |

PE.032.159 |

3.2 | 15.9 |

PE.032.191 |

3.2 | 19.1 |

PE.048.127 |

4.8 | 12.7 |

PE.048.159 |

4.8 | 15.9 |

PE.048.191 |

4.8 | 19.1 |

PE.048.222 |

4.8 | 22.2 |

PE.080.159 |

8.0 | 15.9 |

PE.080.191 |

8.0 | 19.1 |

PE.080.222 |

8.0 | 22.2 |

PE.080.254 |

8.0 | 25.4 |

PE.095.320 |

9.5 | 32.0 |

DOUBLE P section

| P/N | Height [mm] |

Width [mm] |

|---|---|---|

BE.032.095 |

3.2 | 9.5 |

BE.032.127 |

3.2 | 12.7 |

BE.032.159 |

3.2 | 15.9 |

BE.032.191 |

3.2 | 19.1 |

BE.048.159 |

4.8 | 15.9 |

BE.048.191 |

4.8 | 19.1 |

BE.048.222 |

4.8 | 22.2 |

BE.048.254 |

4.8 | 25.4 |

BE.080.191 |

8.0 | 19.1 |

BE.080.222 |

8.0 | 22.2 |

BE.080.254 |

8.0 | 25.4 |

BE.080.320 |

8.0 | 32.0 |

BE.095.320 |

9.5 | 32.0 |

Shielding performances comparison

This graph compares general performances in E-fieldand H-field screening of four gaskets made of different materials (monel, stainless steel, tinned copper and aluminium). Tests are performed on type T.064.SS.2-XX, with round cross-section and silicone sponge core, in accordance with MIL STD 285

MONEL

Material No. (DIN) 2.4360

Wire Diameter 0,11 mm

Test gasket TE.064.SS.2-MO

Shielding Effectiveness

| Electrical | ||

|---|---|---|

| Frequency [Hz] | Mode | Screening [dB] |

| 1 M | E | 124,5 |

| 10 M | E | 107 |

| 110 M | P | 105,5 |

| 400 M | P | 98 |

| 1 G | P | 82 |

| 10 G | P | 62 |

| Magnetic | ||

| 10 K | H | 37 |

| 100 K | H | 40 |

| 1M | H | 44,5 |

Tinned Copper Clad Steel

ASTM-B-520

Wire Diameter 0,11 mm

Test gasket TE.064.SS.2-TC

Shielding Effectiveness

| Electrical | ||

|---|---|---|

| Frequency [Hz] | Mode | Screening [dB] |

| 1 M | E | 125,5 |

| 10 M | E | 109 |

| 110 M | P | 110 |

| 400 M | P | 99,5 |

| 1 G | P | 63 |

| 10 G | P | 58 |

| Magnetic | ||

| 10 K | H | 38 |

| 100 K | H | 62,5 |

| 1M | H | 79 |

Stainless Steel

AISI 304 , Material (DIN) 1.4301

Wire Diameter 0,11 mm

Test gasket TE.064.SS.2-SL

Shielding Effectiveness

| Electrical | ||

|---|---|---|

| Frequency [Hz] | Mode | Screening [dB] |

| 1 M | E | 125,5 |

| 10 M | E | 109 |

| 110 M | P | 110 |

| 400 M | P | 99,5 |

| 1 G | P | 63 |

| 10 G | P | 58 |

| Magnetic | ||

| 10 K | H | 38 |

| 100 K | H | 62,5 |

| 1M | H | 79 |

Aluminium

Alloy 5056 , AMS-4182

Wire Diameter 0,13 mm

Test gasket TE.064.SS.2-AL

Shielding Effectiveness

| Electrical | ||

|---|---|---|

| Frequency [Hz] | Mode | Screening [dB] |

| 1 M | E | 125,5 |

| 10 M | E | 109 |

| 110 M | P | 110 |

| 400 M | P | 99,5 |

| 1 G | P | 63 |

| 10 G | P | 58 |

| Magnetic | ||

| 10 K | H | 38 |

| 100 K | H | 62,5 |

| 1M | H | 79 |

Tests performed in accordance with MIL STD 285

Да ли вас занима овај производ? Да ли су вам потребне додатне информације или појединачне цене?

морате бити пријављени

Elastomer core gasketsare made of a resilient rubber core, knitted over by layers of wire mesh (most common istwo layers). The knitted wire element provides EMI shielding effectiveness, while the elastomer core enables the gasket section to recover more quickly, following repeated compressions. Elastomer core gasketsare used where the application requires a conformable EMI seal and even where a dust protection is needed.

Available materials:

Complete the P/N with

2- letters core suffix ; the number of layers (2 is standard) ;

2- letters METAL SUFFIX.

And wire materials:

Mechanical tolerances

1,5-5 mm +0,3 -0,3 mm

5,5-12 mm +0,6 -0,6 mm

>12 mm +0,9 -0,9 mm

BE.048.159.ST.2-MO

double P section, 4.8x15.9 mm , 2 layers of Monel wire over Silicone Tube

Round

| P/N | Diameter [mm] |

|---|---|

TE.016 |

1.6 |

TE.024 |

2.4 |

TE.032 |

3.2 |

TE.048 |

4.8 |

TE.064 |

6.4 |

TE.080 |

8.0 |

TE.095 |

9.5 |

TE.111 |

11.1 |

TE.127 |

12.7 |

TE.159 |

15.9 |

TE.191 |

19.1 |

Rectangular

| P/N | Height [mm] |

Width [mm] |

|---|---|---|

RE.024.024 |

2.4 | 2.4 |

RE.024.048 |

2.4 | 4.8 |

RE.024.064 |

2.4 | 6.4 |

RE.032.032 |

3.2 | 3.2 |

RE.032.064 |

3.2 | 6.4 |

RE.032.080 |

3.2 | 8.0 |

RE.048.048 |

4.8 | 4.8 |

RE.048.080 |

4.8 | 8.0 |

RE.048.127 |

4.8 | 12.7 |

RE.064.064 |

6.4 | 6.4 |

RE.064.127 |

6.4 | 12.7 |

RE.080.127 |

8.0 | 12.7 |

RE.095.127 |

9.5 | 12.7 |

P section

| P/N | Height [mm] |

Width [mm] |

|---|---|---|

PE.032.095 |

3.2 | 9.5 |

PE.032.127 |

3.2 | 12.7 |

PE.032.159 |

3.2 | 15.9 |

PE.032.191 |

3.2 | 19.1 |

PE.048.127 |

4.8 | 12.7 |

PE.048.159 |

4.8 | 15.9 |

PE.048.191 |

4.8 | 19.1 |

PE.048.222 |

4.8 | 22.2 |

PE.080.159 |

8.0 | 15.9 |

PE.080.191 |

8.0 | 19.1 |

PE.080.222 |

8.0 | 22.2 |

PE.080.254 |

8.0 | 25.4 |

PE.095.320 |

9.5 | 32.0 |

DOUBLE P section

| P/N | Height [mm] |

Width [mm] |

|---|---|---|

BE.032.095 |

3.2 | 9.5 |

BE.032.127 |

3.2 | 12.7 |

BE.032.159 |

3.2 | 15.9 |

BE.032.191 |

3.2 | 19.1 |

BE.048.159 |

4.8 | 15.9 |

BE.048.191 |

4.8 | 19.1 |

BE.048.222 |

4.8 | 22.2 |

BE.048.254 |

4.8 | 25.4 |

BE.080.191 |

8.0 | 19.1 |

BE.080.222 |

8.0 | 22.2 |

BE.080.254 |

8.0 | 25.4 |

BE.080.320 |

8.0 | 32.0 |

BE.095.320 |

9.5 | 32.0 |

Shielding performances comparison

This graph compares general performances in E-fieldand H-field screening of four gaskets made of different materials (monel, stainless steel, tinned copper and aluminium). Tests are performed on type T.064.SS.2-XX, with round cross-section and silicone sponge core, in accordance with MIL STD 285

MONEL

Material No. (DIN) 2.4360

Wire Diameter 0,11 mm

Test gasket TE.064.SS.2-MO

Shielding Effectiveness

| Electrical | ||

|---|---|---|

| Frequency [Hz] | Mode | Screening [dB] |

| 1 M | E | 124,5 |

| 10 M | E | 107 |

| 110 M | P | 105,5 |

| 400 M | P | 98 |

| 1 G | P | 82 |

| 10 G | P | 62 |

| Magnetic | ||

| 10 K | H | 37 |

| 100 K | H | 40 |

| 1M | H | 44,5 |

Tinned Copper Clad Steel

ASTM-B-520

Wire Diameter 0,11 mm

Test gasket TE.064.SS.2-TC

Shielding Effectiveness

| Electrical | ||

|---|---|---|

| Frequency [Hz] | Mode | Screening [dB] |

| 1 M | E | 125,5 |

| 10 M | E | 109 |

| 110 M | P | 110 |

| 400 M | P | 99,5 |

| 1 G | P | 63 |

| 10 G | P | 58 |

| Magnetic | ||

| 10 K | H | 38 |

| 100 K | H | 62,5 |

| 1M | H | 79 |

Stainless Steel

AISI 304 , Material (DIN) 1.4301

Wire Diameter 0,11 mm

Test gasket TE.064.SS.2-SL

Shielding Effectiveness

| Electrical | ||

|---|---|---|

| Frequency [Hz] | Mode | Screening [dB] |

| 1 M | E | 125,5 |

| 10 M | E | 109 |

| 110 M | P | 110 |

| 400 M | P | 99,5 |

| 1 G | P | 63 |

| 10 G | P | 58 |

| Magnetic | ||

| 10 K | H | 38 |

| 100 K | H | 62,5 |

| 1M | H | 79 |

Aluminium

Alloy 5056 , AMS-4182

Wire Diameter 0,13 mm

Test gasket TE.064.SS.2-AL

Shielding Effectiveness

| Electrical | ||

|---|---|---|

| Frequency [Hz] | Mode | Screening [dB] |

| 1 M | E | 125,5 |

| 10 M | E | 109 |

| 110 M | P | 110 |

| 400 M | P | 99,5 |

| 1 G | P | 63 |

| 10 G | P | 58 |

| Magnetic | ||

| 10 K | H | 38 |

| 100 K | H | 62,5 |

| 1M | H | 79 |

Tests performed in accordance with MIL STD 285

Vaša zahvalnost na komentar ne može biti registrovana

Prijavite nepristojan komentar

Prija nepristojnog komentara registrovana

Vaša prijava nepristojnog komentara ne može biti registrovana

Napišite vaš komentar

Komentar poslat

Vaš komentar ne može biti registrovan