Морате бити пријављени да

Category

Фотографије су само у информативне сврхе. Погледајте спецификацију производа

please use latin characters

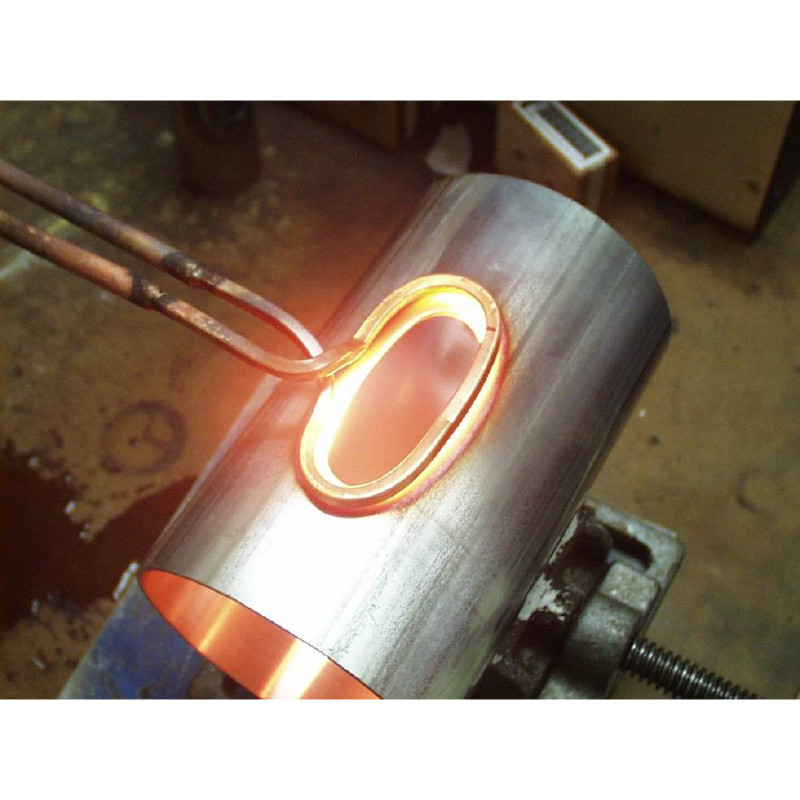

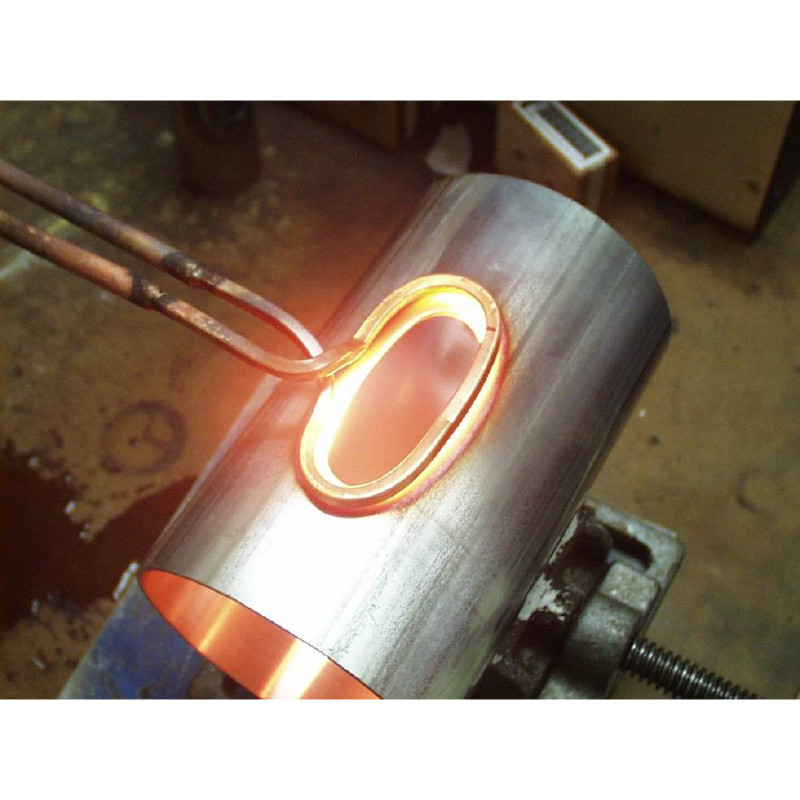

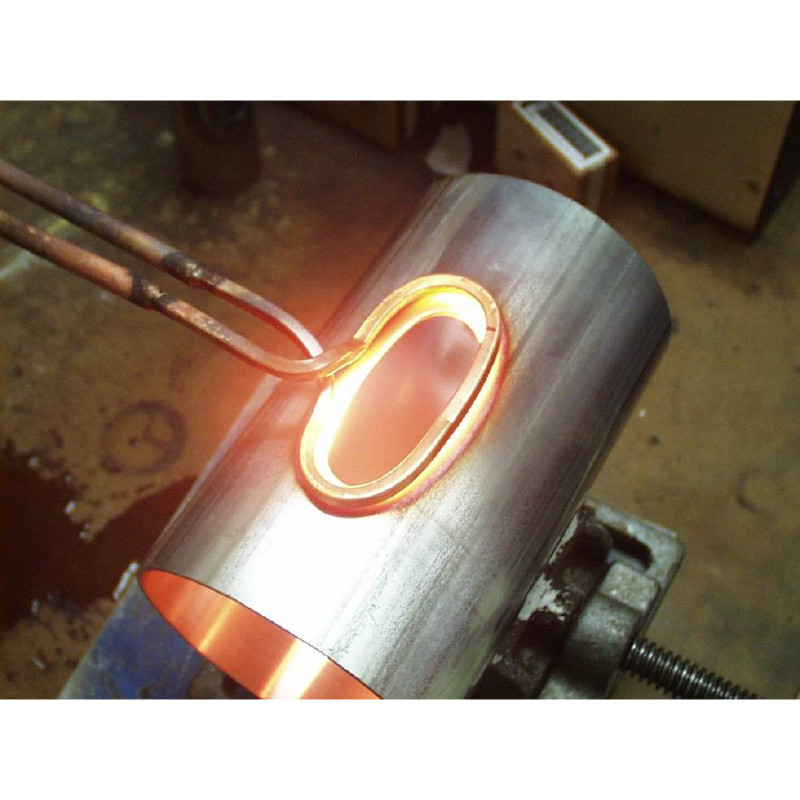

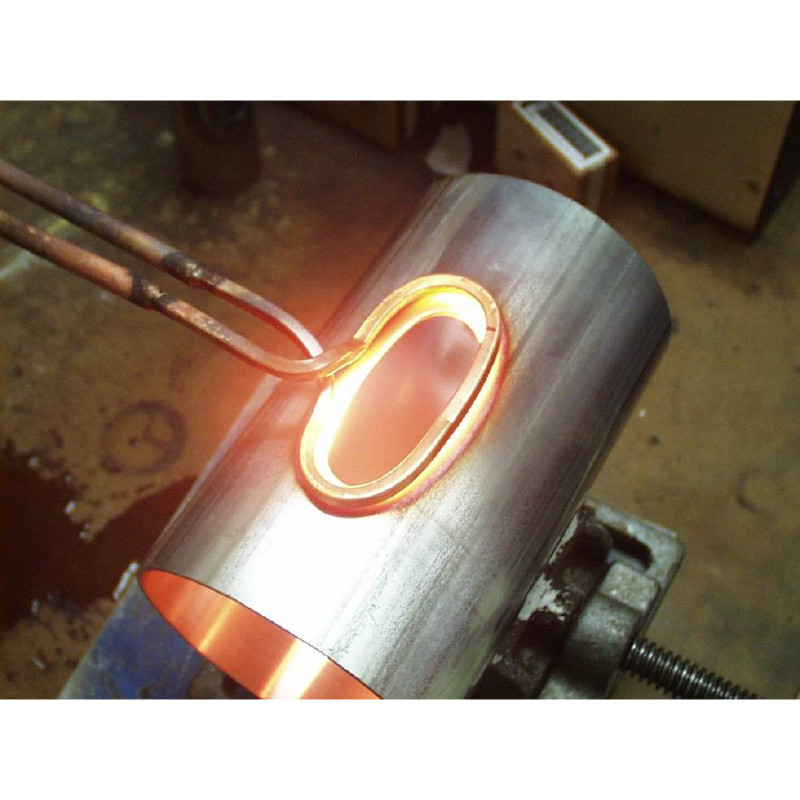

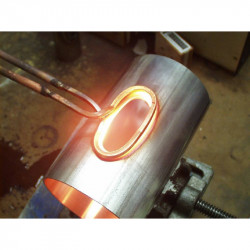

Objective: To anneal a ¼” area around an oval cutout on a stainless steel tube prior to extrusion.

Frequency: 300 kHz

Material: .75” (19mm), 1.5” (38.1mm) and 4” (101.6mm) diameter steel tubes

Temperature: 1900 °F (1038 °C)

A single turn helical coil is used on the 4” (101.6mm) diameter tubes and a two turn helical coil is used on the smaller diameters. The coil is placed over the oval cutout and power is supplied for 15 seconds to anneal a 0.25" (6.35mm) diameter around the cutout.

Да ли вас занима овај производ? Да ли су вам потребне додатне информације или појединачне цене?

морате бити пријављени

Objective: To anneal a ¼” area around an oval cutout on a stainless steel tube prior to extrusion.

Frequency: 300 kHz

Material: .75” (19mm), 1.5” (38.1mm) and 4” (101.6mm) diameter steel tubes

Temperature: 1900 °F (1038 °C)

A single turn helical coil is used on the 4” (101.6mm) diameter tubes and a two turn helical coil is used on the smaller diameters. The coil is placed over the oval cutout and power is supplied for 15 seconds to anneal a 0.25" (6.35mm) diameter around the cutout.

Vaša zahvalnost na komentar ne može biti registrovana

Prijavite nepristojan komentar

Prija nepristojnog komentara registrovana

Vaša prijava nepristojnog komentara ne može biti registrovana

Napišite vaš komentar

Komentar poslat

Vaš komentar ne može biti registrovan