Морате бити пријављени да

Category

Фотографије су само у информативне сврхе. Погледајте спецификацију производа

please use latin characters

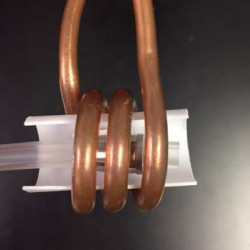

Objective: To heat steel tubes for an adhesive bonding application for a medical industry part.

Frequency: 230 kHz

Material: A stainless steel tube on a plastic tube

Temperature: 392 °F (200 °C)

Initial tests were conducted to optimize the power delivered to the plastic tube assembly. Temperature indicating paint was then applied to the part, which dissolves when the part reaches the target temperature. It was observed that it took 5.0 seconds to heat the sample to temperature. After the part cooled to room temperature, it was compared to the customer-provided finished assemblies to confirm that the plastic was sufficiently bonded to the inside of the steel tube. Five assemblies were heated and the application was successfully proven out.

Да ли вас занима овај производ? Да ли су вам потребне додатне информације или појединачне цене?

морате бити пријављени

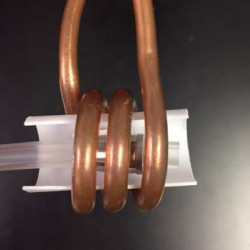

Objective: To heat steel tubes for an adhesive bonding application for a medical industry part.

Frequency: 230 kHz

Material: A stainless steel tube on a plastic tube

Temperature: 392 °F (200 °C)

Initial tests were conducted to optimize the power delivered to the plastic tube assembly. Temperature indicating paint was then applied to the part, which dissolves when the part reaches the target temperature. It was observed that it took 5.0 seconds to heat the sample to temperature. After the part cooled to room temperature, it was compared to the customer-provided finished assemblies to confirm that the plastic was sufficiently bonded to the inside of the steel tube. Five assemblies were heated and the application was successfully proven out.

Vaša zahvalnost na komentar ne može biti registrovana

Prijavite nepristojan komentar

Prija nepristojnog komentara registrovana

Vaša prijava nepristojnog komentara ne može biti registrovana

Write your review

Komentar poslat

Vaš komentar ne može biti registrovan