Морате бити пријављени да

Category

Фотографије су само у информативне сврхе. Погледајте спецификацију производа

please use latin characters

|

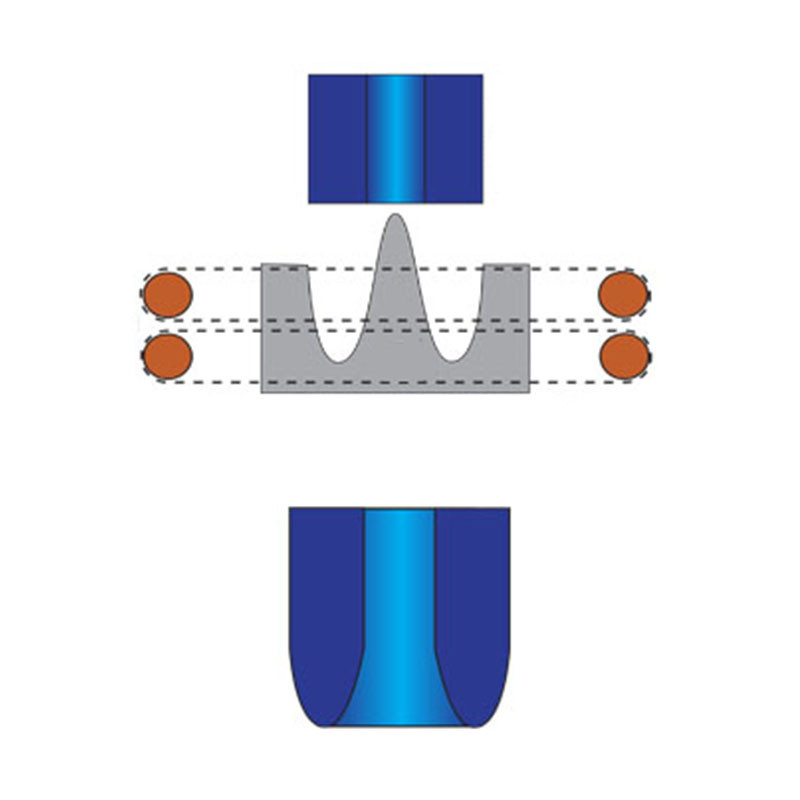

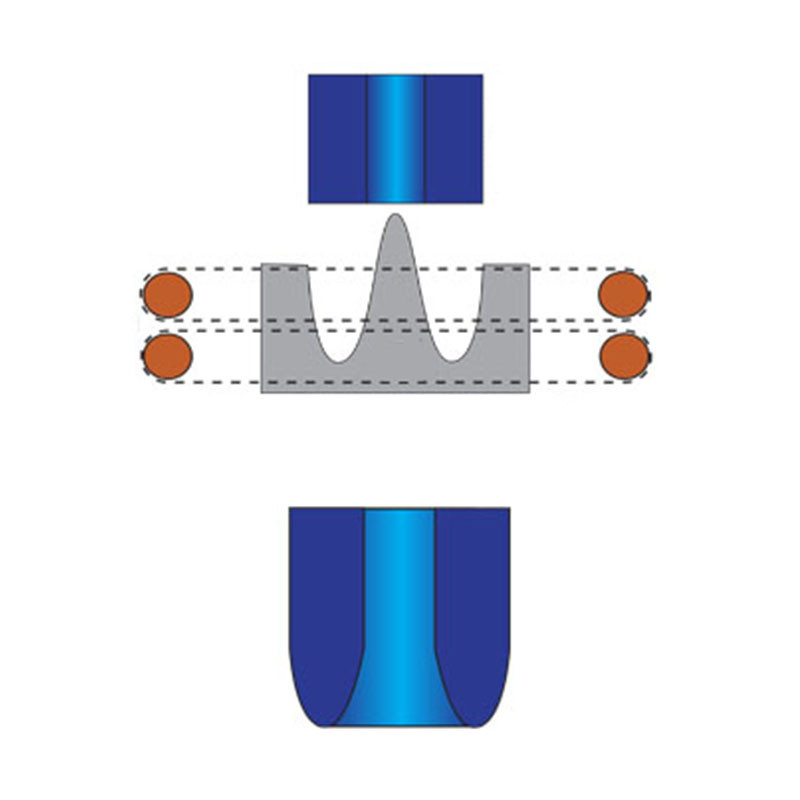

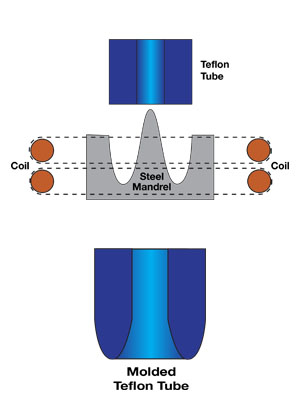

Objective: Heat a water-cooled steel mandrel to 700°F (371ºC) to form a high quality Teflon catheter tip. Material: Teflon catheter tubing, mandrel assembly Temperature: 600-700°F (315.6-371ºC) Frequency: 376 kHz Equipment:

Process: A two turn coil is used to heat the steel mandrel to 660ºF (371.1ºC) in 2.7 seconds. To form the catheter tip, RF power is applied while the catheter is held over the mandrel. The tubing is then pushed on to the mandrel to form a consistent, even tip. Benefits:

|

|

Да ли вас занима овај производ? Да ли су вам потребне додатне информације или појединачне цене?

морате бити пријављени

|

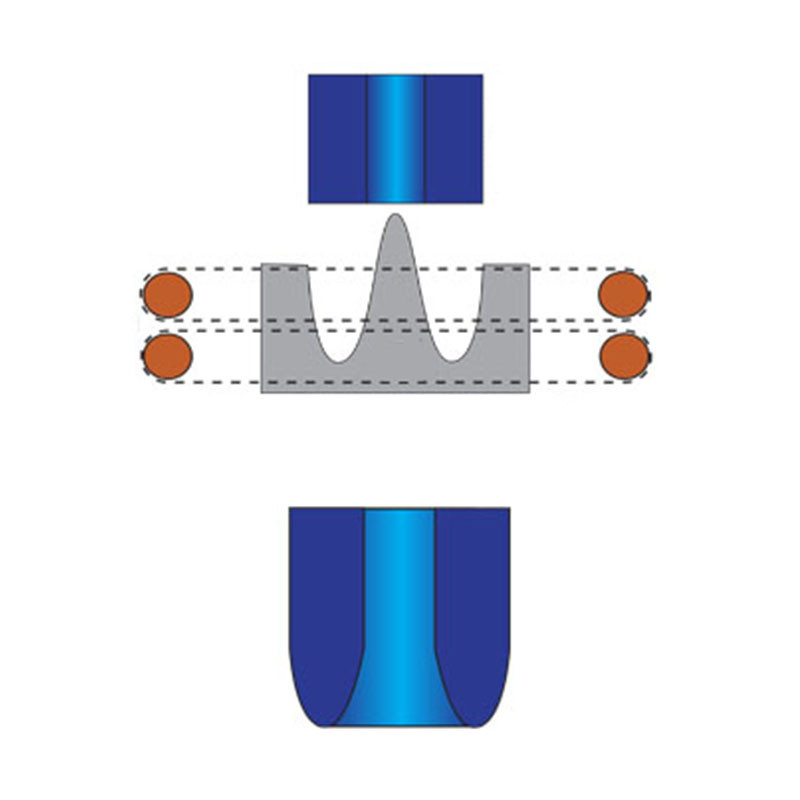

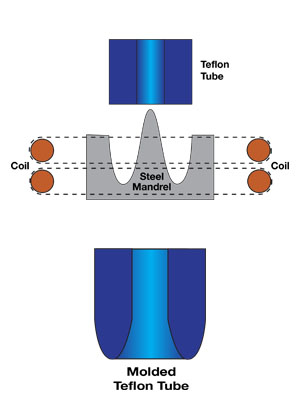

Objective: Heat a water-cooled steel mandrel to 700°F (371ºC) to form a high quality Teflon catheter tip. Material: Teflon catheter tubing, mandrel assembly Temperature: 600-700°F (315.6-371ºC) Frequency: 376 kHz Equipment:

Process: A two turn coil is used to heat the steel mandrel to 660ºF (371.1ºC) in 2.7 seconds. To form the catheter tip, RF power is applied while the catheter is held over the mandrel. The tubing is then pushed on to the mandrel to form a consistent, even tip. Benefits:

|

|

Vaša zahvalnost na komentar ne može biti registrovana

Prijavite nepristojan komentar

Prija nepristojnog komentara registrovana

Vaša prijava nepristojnog komentara ne može biti registrovana

Napišite vaš komentar

Komentar poslat

Vaš komentar ne može biti registrovan