Морате бити пријављени да

-

moreX

-

Компоненте

-

-

Category

-

Полупроводници

- диоде

- Тиристори

-

Електро изоловани модули

- Електро изоловани модули | ВИСХАИ (ИР)

- Електро изоловани модули | ИНФИНЕОН (ЕУПЕЦ)

- Електро изоловани модули | Семикрон

- Електро изоловани модули | ПОВЕРЕКС

- Електро изоловани модули | ИКСИС

- Електро изоловани модули | ПОСЕИЦО

- Електро изоловани модули | АББ

- Електро изоловани модули | ТЕЦХСЕМ

- Go to the subcategory

- Мостовни исправљачи

-

Транзистори

- Транзистори | GeneSiC

- SiC MOSFET модули | Mitsubishi

- SiC MOSFET модули | STARPOWER

- АББ СиЦ МОСФЕТ модули

- IGBT модули | MITSUBISHI

- Транзисторски модули | MITSUBISHI

- MOSFET модули | MITSUBISHI

- Транзисторски модули | ABB

- ИГБТ модули | POWEREX

- ИГБТ модули | ИНФИНЕОН (ЕУПЕЦ)

- Silicijum-karbidni poluprovodnički elementi

- Go to the subcategory

- Гате Дриверс

- Блокови напајања

- Go to the subcategory

- Električni pretvarači

-

Пасивне компоненте (кондензатори, отпорници, осигурачи, филтери)

- Otpornici

-

Osigurači

- Minijaturni osigurači za elektronske sisteme serije ABC i AGC

- Cilindrični brzi osigurači

- Osigurači sa odloženim delovanjem GL/GG i AM karakteristika

- Ultra-brzi osigurači

- Brzi osigurači sa britanskim i američkim standardom

- Brzi osigurači sa evropskim standardom

- Vučni osigurači

- Visokonaponski osigurači

- Go to the subcategory

-

Kondenzatori

- Motorni kondenzatori

- Elektrolitski kondenzatori

- Kondenzatori - snubberi

- Energetski kondenzatori

- Kondenzatori za DC kola

- kondenzatori za kompenzaciju snage

- Visokonaponski kondenzatori

- Kondenzatori za indukciono grejanje

- Impulsni kondenzatori

- ДЦ ЛИНК кондензатори

- Кондензатори за АЦ/ДЦ кола

- Go to the subcategory

- EMI filtri

- Superkondenzatori

- Заштита од пренапона

- Go to the subcategory

-

Releji i kontaktori

- Теорија релеја и склопника

- Trofazni poluprovodnički releji

- Трофазни полупроводнички релеји наизменичне струје

- Регулатори, команде и додаци

- Sistemi za meki sart i reverziblni kontaktori

- Elektromehanički releji

- Kontaktori

- Rotacioni prekidači

-

Једнофазни полупроводнички релеји наизменичне струје

- Једнофазни релеји наизменичне струје, 1 серија | Д2425 | Д2450

- Jednofazni poluvodički izmjenični releji CWA i CWD serije

- Jednofazni poluvodički izmjenični releji CMRA i CMRD serije

- Jednofazni poluvodički izmjenični releji - serija PS

- Двоструки и четвороструки полупроводнички релеји наизменичне струје, серије Д24 Д, ТД24 К, Х12Д48 Д.

- Jednofazni poluvodički releji - gn serije

- Jednofazni kružni releji Ckr serije

- Jednofazni AC poluvodički releji za DIN sabirnice - ERDA I ERAA serija

- 150A AC jednofazni releji

- Čvrsti releji s ugrađenim hladnjakom na šini - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Monofazni poluprovodnički releji za štampane ploče

- Интерфејс релеји

- Go to the subcategory

- Indukcione komponenete

- Radijatori, Varistori, Termička zaštita

- Ventilatori

- Klimatizacija, Pribor za industrijska kućišta, Kuleri

-

Батерије, пуњачи, бафер напајања и претварачи

- Батерије, пуњачи - теоријски опис

- Litijum-jonske baterije. Nestandardne baterije. Sistem za upravljanje baterijom (BMS)

- Baterije

- Punjači i dodaci za baterije

- UPS i puferski izvori napajanja

- Pretvarači i dodaci- fotonaponski

- Складиште енергије

- Гориве ћелије

- Литијум-јонске батерије

- Go to the subcategory

-

Automatika

- Futaba Drone Parts

- Крајњи прекидачи, микро прекидачи

- Сензори, претварачи

- Пирометрија

- Бројачи, тајмери, панел мерачи

- Индустријски заштитни уређаји

- Светлосна и звучна сигнализација

- Термовизијска камера

- ЛЕД дисплеји

- Тастери и прекидачи

-

Снимачи

- Снимач АЛ3000

- КР2000 снимач

- Снимач КР5000

- ХН-ЦХ мерач са функцијом регистрације влажности и температуре

- Потрошни материјал за снимаче

- 71ВР1 снимач

- Снимач КР 3000

- ПЦ снимачи серије Р1М

- ПЦ снимачи серије Р2М

- ПЦ снимач, 12 изолованих улаза - РЗМС-У9

- ПЦ снимач, УСБ, 12 изолованих улаза - РЗУС

- Go to the subcategory

- Go to the subcategory

-

Kablovi, Licnaste žice, Kablovski kanali, Fleksibilne veze

- жице

- лицнастим жице

- Каблови за специјалне намене

- схиртс

-

плетенице

- браидс флат

- плетенице коло

- Врло флексибилан плетеница - стан

- Врло флексибилан плетеница - коло

- Бакар плетена цилиндрични

- Бакра плетеница штит и цилиндрични

- Флексибилни уземљење траке

- Плетенице ЦИЛИНДРИЦАЛ поцинковани и нерђајућег челика

- ПВЦ изолацијом бакарне плетенице - Температура 85 ° Ц

- Стан плетени алуминијум

- Цоннецтион Кит - плетенице и цеви

- Go to the subcategory

- Прибор за вучу

- папучица

- Флексибилни исолатед сабирнице

- Вишеслојна флексибилан шина

- системи за управљање кабл

- Водове, цеви

- Go to the subcategory

- View all categories

-

Полупроводници

-

-

- Suppliers

-

Applications

- Automatika industrijska

- CNC alatni strojevi

- DC i izmjenični pogoni (pretvarači)

- Energy bank

- Indukciono grejanje

- Industrijski zaštitni uređaji

- Istraživanje i laboratorijska merenja

- Mašine za sušenje i obradu drveta

- Mašine za termoformiranje

- Merenje i regulacija temperature

- Motori i transformatori

- Oprema i dijelovi za opasna područja (EX)

- Oprema za centrale, kontrolne ormare i telekomunikacije

- Poligrafija

- Rudarstvo, metalurgija i livnica

- Tramvajska i železnička vuča

- UPS i ispravljački sistemi

- Апарати за заваривање и апарати за заваривање

- Индустријска аутоматизација

- ХВАЦ аутоматизација

-

Инсталација

-

-

Индуктори

-

-

Индукциони уређаји

-

-

https://www.dacpol.eu/pl/naprawy-i-modernizacje

-

-

Услуга

-

- Kontakt

- Zobacz wszystkie kategorie

Optimizacija napajanja: izazovi, tehnologije i rešenja

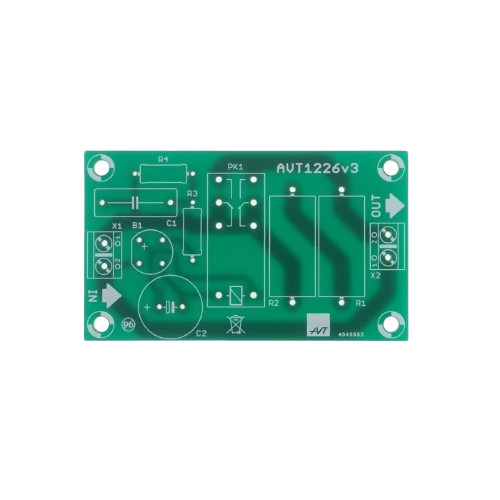

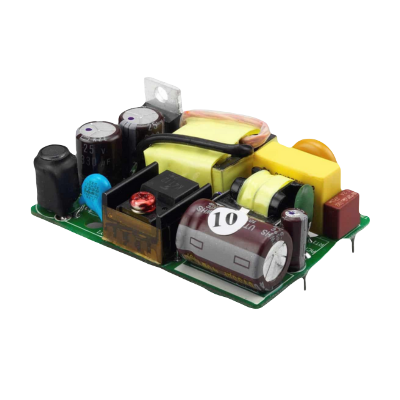

Contemporary power supply systems on PCBs (Printed Circuit Board) are a crucial element in the development of new electronic devices. Requirements related to miniaturization, energy efficiency, and operational stability pose significant challenges for designers. Products such as power supplies, converters, and voltage regulation systems must meet increasingly stringent standards regarding energy, space, and performance[1].

Challenges in Power Supply Design

The challenges related to power supply design encompass technical, economic, and environmental aspects. Notable difficulties include:

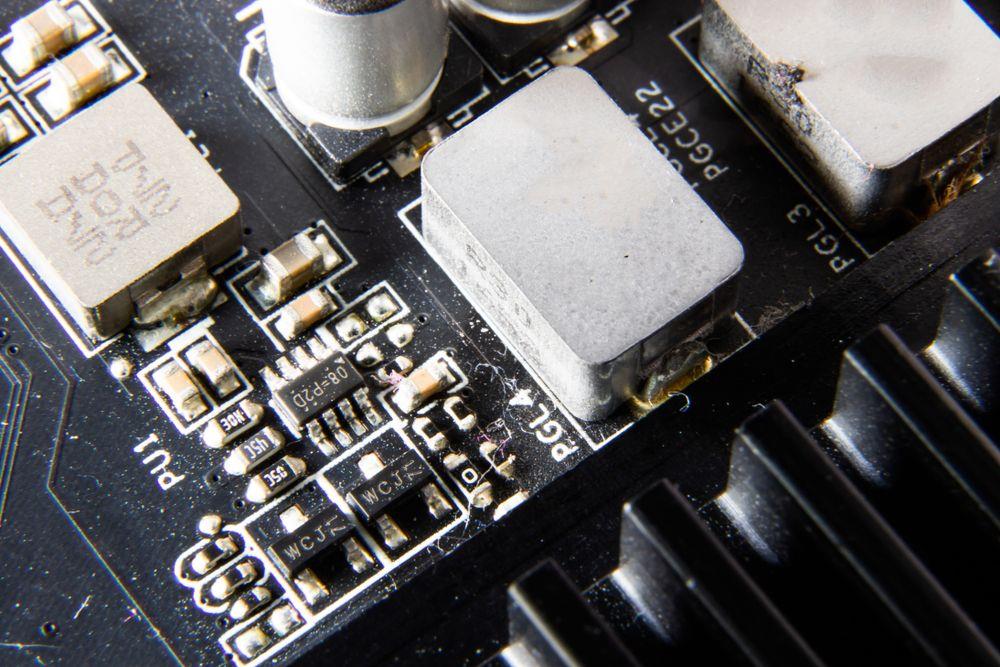

- Miniaturization of components - Devices are becoming smaller, requiring power supply designs with high efficiency in limited space[2].

- Heat management - Improper design can lead to overheating of the system, resulting in failure. The use of heat sinks and fans is crucial for the stability of systems[1].

- Increased energy requirements - Modern technologies require the supply of proper voltage with minimal energy losses[2].

Technologies Used in Power Supply Systems

R&D engineers utilize various technologies to address design challenges:

- DC-DC converters: Enable voltage adjustment to meet component requirements. Buck and boost technologies allow for lowering or increasing the voltage, while buck-boost models offer flexibility with various input voltages[3].

- AC-DC converters: Provide conversion of energy from alternating current to direct current, which is essential for applications powered by the electrical grid[4].

- Voltage regulators: Crucial for ensuring proper power quality for sensitive components[1].

Miniaturization and Space Optimization

In the context of miniaturization, new techniques for space optimization on PCBs are emerging:

- System on a Chip (SoC): Allows for reduced PCB size and improved energy efficiency[2].

- Increased operating frequency: Enables reduction in the size of passive components such as capacitors and transformers[3].

- New materials: The use of graphene and advanced magnetic materials contributes to improved energy efficiency and heat management[4].

Prototyping and Diagnostics

Prototypes in R&D require flexible and reliable power systems. Typical challenges include:

- Voltage flexibility: Modular voltage converters allow for quick adaptation of parameters to changing project needs[1].

- Diagnostics: Oscilloscopes and electronic load simulators are used to analyze system performance and identify anomalies[2].

Aerospace, Medical, and Military Industries

In projects related to the aerospace, medical, and military industries, the reliability of power supply systems is critical. In these cases, solutions that minimize the risk of failure are applied, such as power redundancy and advanced cooling technologies[4].

The Future of Power Supply Systems

Looking to the future, R&D engineers must stay updated with new technologies and materials. Power supplies based on Gallium Nitride (GaN) offer significantly higher energy efficiency than traditional silicon components, allowing for the development of smaller converters. Dynamic energy management and miniaturization through multilayer technology (LTCC) are other development trends in the industry[3][4].

All these aspects highlight the importance of solutions in power supply design and their impact on the development of modern electronic devices.

Bibliography:

[1] https://resources.altium.com/pl/p/guide-pcb-power-supply-layout

[2] https://evertiq.pl/design/19262

[3] https://www.tcl.com/pl/pl/blog/guides/what-is-pcb-the-advantages-of-using-it-in-ac

[4] https://forbot.pl/blog/katalog-firm/montaz-plytek-drukowanych-pcb-co-warto-wiedziec

[5] https://propcb.pl/technologie/

[6] https://elektronikab2b.pl/technika/54036-projektowanie-pcb-dla-ukladow-duzej-mocy

[7] https://hilelectronic.com/pl/design-power-pcb/

[8] https://home.agh.edu.pl/~ggora/lectures/ProjektowaniePCB.pdf

Related products

Related posts

Thermally conductive materials in power storages

Thermally conductive materials in power storages

Folia samoprzylepna z wypełnieniem ceramicznym

Folia samoprzylepna z wypełnieniem ceramicznym

Управљање топлотом – Изазови за електрична возила

Управљање топлотом – Изазови за електрична возила

Leave a comment