Морате бити пријављени да

-

moreX

-

Компоненте

-

-

Category

-

Полупроводници

- диоде

- Тиристори

-

Електро изоловани модули

- Електро изоловани модули | ВИСХАИ (ИР)

- Електро изоловани модули | ИНФИНЕОН (ЕУПЕЦ)

- Електро изоловани модули | Семикрон

- Електро изоловани модули | ПОВЕРЕКС

- Електро изоловани модули | ИКСИС

- Електро изоловани модули | ПОСЕИЦО

- Електро изоловани модули | АББ

- Електро изоловани модули | ТЕЦХСЕМ

- Go to the subcategory

- Мостовни исправљачи

-

Транзистори

- Транзистори | GeneSiC

- SiC MOSFET модули | Mitsubishi

- SiC MOSFET модули | STARPOWER

- АББ СиЦ МОСФЕТ модули

- IGBT модули | MITSUBISHI

- Транзисторски модули | MITSUBISHI

- MOSFET модули | MITSUBISHI

- Транзисторски модули | ABB

- ИГБТ модули | POWEREX

- ИГБТ модули | ИНФИНЕОН (ЕУПЕЦ)

- Silicijum-karbidni poluprovodnički elementi

- Go to the subcategory

- Гате Дриверс

- Блокови напајања

- Go to the subcategory

- Električni pretvarači

-

Пасивне компоненте (кондензатори, отпорници, осигурачи, филтери)

- Otpornici

-

Osigurači

- Minijaturni osigurači za elektronske sisteme serije ABC i AGC

- Cilindrični brzi osigurači

- Osigurači sa odloženim delovanjem GL/GG i AM karakteristika

- Ultra-brzi osigurači

- Brzi osigurači sa britanskim i američkim standardom

- Brzi osigurači sa evropskim standardom

- Vučni osigurači

- Visokonaponski osigurači

- Go to the subcategory

-

Kondenzatori

- Motorni kondenzatori

- Elektrolitski kondenzatori

- Kondenzatori - snubberi

- Energetski kondenzatori

- Kondenzatori za DC kola

- kondenzatori za kompenzaciju snage

- Visokonaponski kondenzatori

- Kondenzatori za indukciono grejanje

- Impulsni kondenzatori

- ДЦ ЛИНК кондензатори

- Кондензатори за АЦ/ДЦ кола

- Go to the subcategory

- EMI filtri

- Superkondenzatori

- Заштита од пренапона

- TEMPEST филтери за откривање емисије

- Одводник пренапона

- Go to the subcategory

-

Releji i kontaktori

- Теорија релеја и склопника

- Trofazni poluprovodnički releji

- Трофазни полупроводнички релеји наизменичне струје

- Регулатори, команде и додаци

- Sistemi za meki sart i reverziblni kontaktori

- Elektromehanički releji

- Kontaktori

- Rotacioni prekidači

-

Једнофазни полупроводнички релеји наизменичне струје

- Једнофазни релеји наизменичне струје, 1 серија | Д2425 | Д2450

- Jednofazni poluvodički izmjenični releji CWA i CWD serije

- Jednofazni poluvodički izmjenični releji CMRA i CMRD serije

- Jednofazni poluvodički izmjenični releji - serija PS

- Двоструки и четвороструки полупроводнички релеји наизменичне струје, серије Д24 Д, ТД24 К, Х12Д48 Д.

- Jednofazni poluvodički releji - gn serije

- Jednofazni kružni releji Ckr serije

- Jednofazni AC poluvodički releji za DIN sabirnice - ERDA I ERAA serija

- 150A AC jednofazni releji

- Čvrsti releji s ugrađenim hladnjakom na šini - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Monofazni poluprovodnički releji za štampane ploče

- Интерфејс релеји

- Go to the subcategory

- Indukcione komponenete

- Radijatori, Varistori, Termička zaštita

- Ventilatori

- Klimatizacija, Pribor za industrijska kućišta, Kuleri

-

Батерије, пуњачи, бафер напајања и претварачи

- Батерије, пуњачи - теоријски опис

- Litijum-jonske baterije. Nestandardne baterije. Sistem za upravljanje baterijom (BMS)

- Baterije

- Punjači i dodaci za baterije

- UPS i puferski izvori napajanja

- Pretvarači i dodaci- fotonaponski

- Складиште енергије

- Гориве ћелије

- Литијум-јонске батерије

- Go to the subcategory

- Automatika

-

Kablovi, Licnaste žice, Kablovski kanali, Fleksibilne veze

- жице

- Кабловски уводи и спојнице

- лицнастим жице

- Каблови за специјалне намене

- схиртс

-

плетенице

- браидс флат

- плетенице коло

- Врло флексибилан плетеница - стан

- Врло флексибилан плетеница - коло

- Бакар плетена цилиндрични

- Бакра плетеница штит и цилиндрични

- Флексибилни уземљење траке

- Плетенице ЦИЛИНДРИЦАЛ поцинковани и нерђајућег челика

- ПВЦ изолацијом бакарне плетенице - Температура 85 ° Ц

- Стан плетени алуминијум

- Цоннецтион Кит - плетенице и цеви

- Go to the subcategory

- Прибор за вучу

- папучица

- Флексибилни исолатед сабирнице

- Вишеслојна флексибилан шина

- системи за управљање кабл

- Go to the subcategory

- View all categories

-

Полупроводници

-

-

- Suppliers

-

Applications

- Automatika industrijska

- CNC alatni strojevi

- DC i izmjenični pogoni (pretvarači)

- Energy bank

- Indukciono grejanje

- Industrijski zaštitni uređaji

- Istraživanje i laboratorijska merenja

- Mašine za sušenje i obradu drveta

- Mašine za termoformiranje

- Merenje i regulacija temperature

- Motori i transformatori

- Oprema i dijelovi za opasna područja (EX)

- Oprema za centrale, kontrolne ormare i telekomunikacije

- Poligrafija

- Rudarstvo, metalurgija i livnica

- Tramvajska i železnička vuča

- UPS i ispravljački sistemi

- Апарати за заваривање и апарати за заваривање

- Индустријска аутоматизација

- ХВАЦ аутоматизација

-

Инсталација

-

-

Индуктори

-

-

Индукциони уређаји

-

-

Услуга

-

- Kontakt

- Zobacz wszystkie kategorie

Vodonične gorivne ćelije - ključne informacije

The technological development and changes in the global industry force the continuous need to search for new energy sources. When it comes to batteries, the focus is not only on high efficiency, capacity, or performance but also on ecology and the ability to operate in various conditions. Therefore, the problem boils down to balancing many factors, and the solutions proposed by manufacturers focus on delivering specialized devices to the market. The electrolyte or the use of substances with properties and parameters that will influence the effectiveness of energy sources is also essential.

A breakthrough in this field has been fuel cells, which, as electrochemical devices, allow the generation of electrical energy and heat from the reactions occurring within them. In short: in fuel cells, the conversion of chemical energy from fuels such as hydrogen, methane, butane, methanol, or gasoline into electrical energy takes place.

DACPOL, addressing these needs and responding to market expectations, has introduced hydrogen-based solutions into its offer, which will be expanded in the future to include other energy sources. Currently, we offer PEM fuel cells of various power ratings, as well as complete power systems containing a ventilation system, converter, and housing.

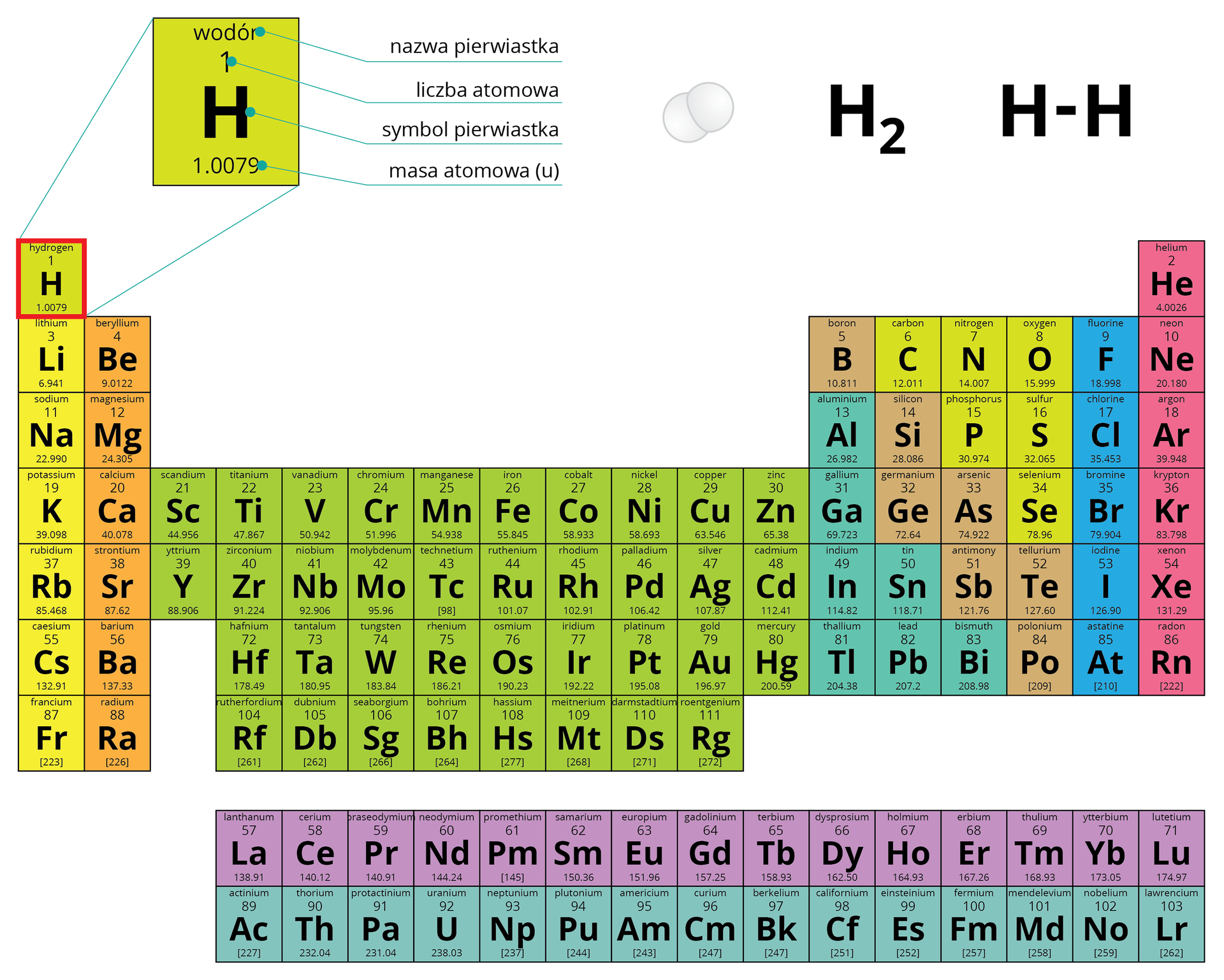

Hydrogen - The simplest and lightest element

It is the simplest (composed of one proton and one electron) and lightest (14 times lighter than air) chemical element that starts the periodic table and accounts for about three-fourths of the mass of the Universe. Hydrogen is contained in water covering about 70% of the Earth's surface, as well as in all organic matter. Under normal conditions, hydrogen is a colorless, tasteless, and odorless gas, slightly soluble in water (0.021 vol. H2 in 1 vol. H2O at 0°C). The low critical temperature of hydrogen (-239.9°C) makes its liquefaction more difficult than that of air and most other gases. Liquefied hydrogen is a colorless liquid with a specific gravity of 0.07 g/cm3. Due to its small molecular mass (2.0158), hydrogen gas exhibits the lowest specific gravity among all gases - 0.08988 g/l at 0°C and 1 atm. Compared to other gases, it also has a high diffusion speed and is the best thermal conductor among them. It is a flammable gas, burning with a clean, carbon- and soot-free flame. In comparison with other popular fuels like gasoline, methane, and propane, hydrogen has a clearly higher calorific value, heat of combustion, ignition energy, and flame speed.

Hydrogen storage

High shares of renewable energy sources in the power system can require long-term and seasonal storage, for example, to provide electricity for several days during periods of very low wind and sunlight.

Hydrogen and hydrogen fuels, such as methane, liquid organic hydrogen carriers (LOHCs), and ammonia produced by electricity through electrolysis, are potential options for long-term and large-scale energy storage. Salt caverns are the best choice for underground storage of pure hydrogen due to their tightness and low risk of contamination. Alternative underground hydrogen storage options are also being explored, such as caves, aquifers, and places left after oil and gas extraction.

Converting electrical energy into methane using energy produced from natural gas is another option for long-term hydrogen storage.

Pure hydrogen is mostly stored in pressure vessels. Few construction materials are used for manufacturing hydrogen storage tanks, as hydrogen significantly increases their brittleness. The best current solution is ultralight composite materials that withstand pressures above 20 bar. These materials are used in prototypes of cars and buses.

Among them, the following should be mentioned:

- Metal tanks made of steel, capable of withstanding 200 bar, or aluminum tanks, capable of withstanding a maximum pressure of 175 bar.

- Aluminum tanks reinforced with fiberglass, aramid, or carbon fibers, capable of withstanding maximum pressures above 250 bar.

- Bottles made of fiberglass/aramid composites or carbon fiber with a metal liner, capable of withstanding maximum pressures of 305 and 438 bar, respectively.

- Bottles made of typical carbon fiber coated with a polymer layer, capable of withstanding pressures above 661 bar.

Carbon Nanofibers - A material of the future for hydrogen storage tanks

Carbon nanofibers, including carbon nanotubes, are the material of the future for manufacturing hydrogen storage tanks. These structures have exceptional electrical and mechanical properties, resembling, under electron microscopy, a mat made from intertwined carbon threads. They conduct heat well and exhibit high strength, making them one of the strongest and stiffest materials discovered to date.

Some tanks are used for long-term hydrogen storage, while others are designed for continuous filling and emptying.

Hydrogen is also stored in liquid form. Liquid hydrogen tanks can be used in transport and portable devices. However, the technology for producing liquid hydrogen requires significant energy input, as it must be cooled to a very low temperature (-252.87°C) once compressed.

The main advantage of storing hydrogen in liquid form, rather than gas, is that it occupies a much smaller volume.

Liquefied hydrogen has found use as rocket fuel in internal combustion engines and fuel cells. During the combustion of hydrogen in a rocket engine, large amounts of energy are generated, releasing water along with trace amounts of ozone and hydrogen peroxide.

Typical hydrogen applications

- Mixtures of argon with hydrogen are used as shielding gases in plasma welding and TIG welding. These mixtures are primarily used when welding austenitic stainless steel and some nickel alloys.

- Hydrogen, combined with argon, can also be used to produce mixtures for plasma cutting (mainly for stainless steel and aluminum). In glass manufacturing, hydrogen is used to polish edges.

- Hydrogen is also used in the production of carbon steels, special metals, and semiconductors.

- In electronics, hydrogen is commonly used as a reducing agent and carrier gas.

- Other processes involving hydrogen include hydrofining of petroleum products, desulfurization of exhaust gases, heat treatment of metals, and leak testing. Hydrogen is also used in various petrochemical and chemical processes.

- Hydrogen is used to power flames in industrial and laboratory burners.

PEM Fuel Cells - How Do Hydrogen Fuel Cells Work?

The PEM (Proton Exchange Membrane or Polymer Electrolyte Membrane) technology involves supplying fuel cells with pure hydrogen or reformate. The membrane in this case is a polymer material such as Nafion. A characteristic feature of PEM fuel cells is their high efficiency in generating electricity – up to 65% – and the low amount of heat generated. Another advantage is the good responsiveness of the cell in systems subjected to varying loads, as well as the short startup time. These properties result from the low reaction temperature within the fuel cell: 60 – 100°C.

The electrolyte allows the flow of cations while preventing the flow of electrons. The chemical reaction within the fuel cell involves splitting hydrogen into protons and electrons at the anode, followed by combining the reaction substrates at the cathode. Electrochemical processes are accompanied by the flow of electrons from the anode to the cathode, bypassing the impermeable membrane. As a result of the electrochemical reaction between hydrogen and oxygen, electric current, water, and heat are produced. The fuel – hydrogen in its pure form or mixed with other gases – is continuously supplied to the anode, and the oxidizer – oxygen in its pure form or a mixture (air) – is continuously supplied to the cathode.

Fuel cells theoretically do not discharge. In practice, degradation or malfunction of components limits their lifespan. The main applications of PEM fuel cells are vehicle propulsion and the construction of stationary or portable power generators.

Advantages of Hydrogen Fuel Cells

High reliability – no moving parts, high quality of the energy supplied. The energy delivered by fuel cells is highly resistant to interference.

Hydrogen fuel cells are an ideal power source for medical devices, measuring equipment, computers, etc. Fuel cells are characterized by high efficiency and energy density.

A fuel cell is always smaller and lighter than other energy sources with comparable power.

Fuel cell efficiency in generating electricity can reach up to 50%. In the process of cogeneration, producing both electricity and heat, fuel cells achieve an efficiency of up to 85%. Various types of fuels can be used in fuel cells.

Fuel cells can be powered by any fuel rich in hydrogen. Hydrogen can be obtained from fuel either inside the fuel cell, through internal reforming, or outside the cell using an external device called a fuel reformer.

Thanks to electrolysis, hydrogen for fuel cells can be produced using alternative energy sources. Pollution resulting from the production of energy using "conventional" methods is a cause of environmental degradation and the emergence of new civilization diseases. A fuel cell produces 25 times fewer pollutants compared to internal combustion generators.

When the fuel cell is powered by hydrogen, the amount of pollutants produced is minimal. Individual fuel cells can be combined to achieve the desired power generation level (scalability). Fuel cell assemblies of different shapes are used to power everything from a single light bulb to industrial machinery. PEM fuel cell applications also include vehicle propulsion and the construction of stationary or portable power generators.

The principle of operation of the hydrogen fuel cell is well known, and progress is currently being made in the development of materials for electrodes, membranes, seals, and catalysts. The goal of research is to extend the lifespan and efficiency of the cell while reducing production costs. Additionally, new technologies for manufacturing fuel cell components are being developed by replacing mechanical processing with precise spray technologies. The effects of this research are already visible to end-users: the lifespan of fuel cells is increasing, and the cost of produced energy is decreasing.

DACPOL's offer includes not only the delivery of fuel cells themselves but also complete systems and support for working with hydrogen technology.

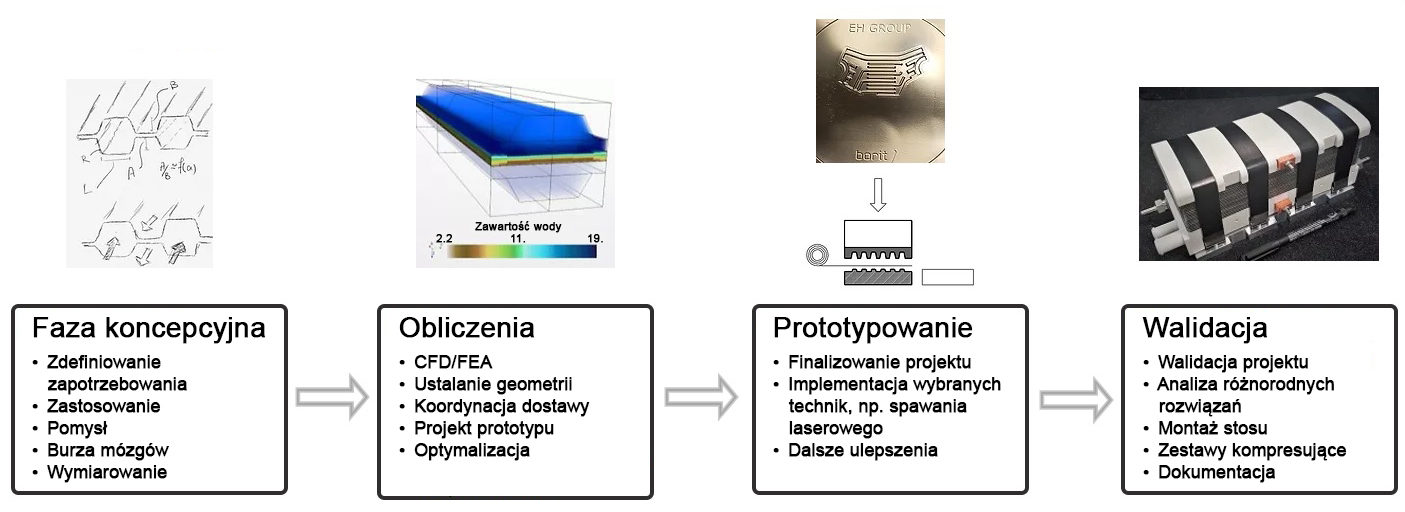

The simplest form of cooperation is the design and construction of a hydrogen fuel cell tailored to the user's individual needs. The requirements may concern not only electrical parameters but also environmental conditions, working conditions, application, or special construction. The production phase is actually the final stage of the entire process, which begins with a thorough understanding of the customer's needs and the establishment of subsequent design steps.

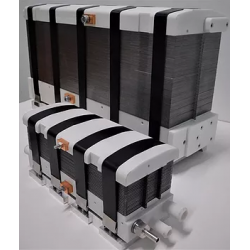

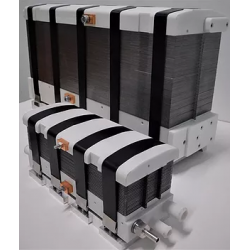

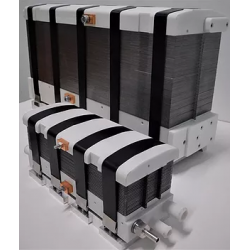

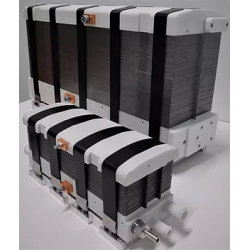

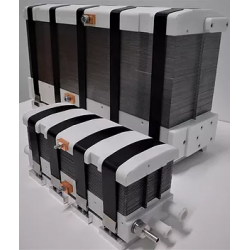

Key characteristics of fuel cells supplied by DACPOL are:

- High energy density, related to the appropriately designed microstructure of the elements comprising the stack,

- Simplified construction making the stack more compact, lighter, and more efficient than similar solutions,

- Scalability enabling the construction of larger solutions (with higher power).

In addition to supplying hydrogen fuel cells as energy sources, DACPOL also offers the possibility of building a complete hydrogen-based power system for the customer. This solution includes the fuel cell, heat exchanger, inverter, and housing for mechanical protection along with assembly. We will also assist in selecting appropriate components if the user already has some of the elements of the above system.

Related products

Related posts

Now available – DC/DC converters from PREMIUM

Now available – DC/DC converters from PREMIUM

New release in DACPOL lighting for lathes – Kira covers

New release in DACPOL lighting for lathes – Kira covers

Leave a comment

Comments

Ogniwa wodorowe

By: Łukasz Konieczniak On 29. 07. 2025.Dzień dobry

Mam prośbę o wycenę paliwa wodorowego22kW z linku: https://www.dacpol.eu/pl/ogniwa-paliwowe-wodorowe/product/ogniwa-paliwowe-wodorowe-eh-81-moc-22-kw

Dodatkowo prośba o podanie wytycznych jakie musze byc parametry zasilania wodorem oraz jakie parametry elektryczne uzyskujemy na wyjściu z ogniwa.

Pozdrawiam

Łukasz Konieczniak

Replied by: Michał DACPOL On 01. 09. 2025.

Pytanie o cenę ogniwa paliwowego o mocy 5.5kW , 12 kW oraz 25kW

By: Tomasz On 15. 11. 2024.Dobieram ogniwo paliwowe do instalacji wodorowej dla zasilania obiektu w zimę. Pozdrawiam,

Replied by: Michał DACPOL On 15. 11. 2024.