Морате бити пријављени да

Category

Фотографије су само у информативне сврхе. Погледајте спецификацију производа

please use latin characters

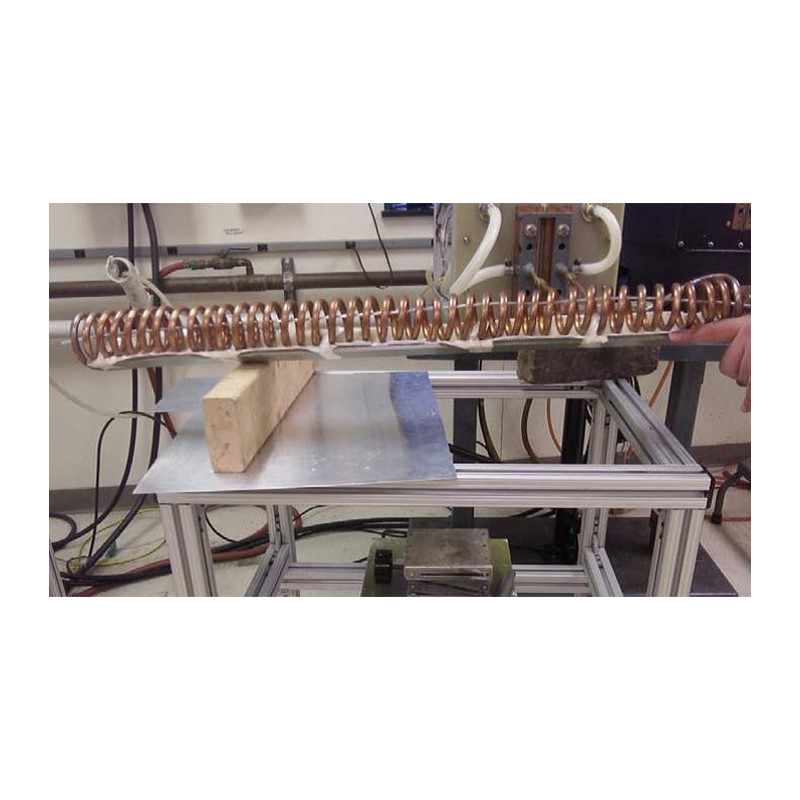

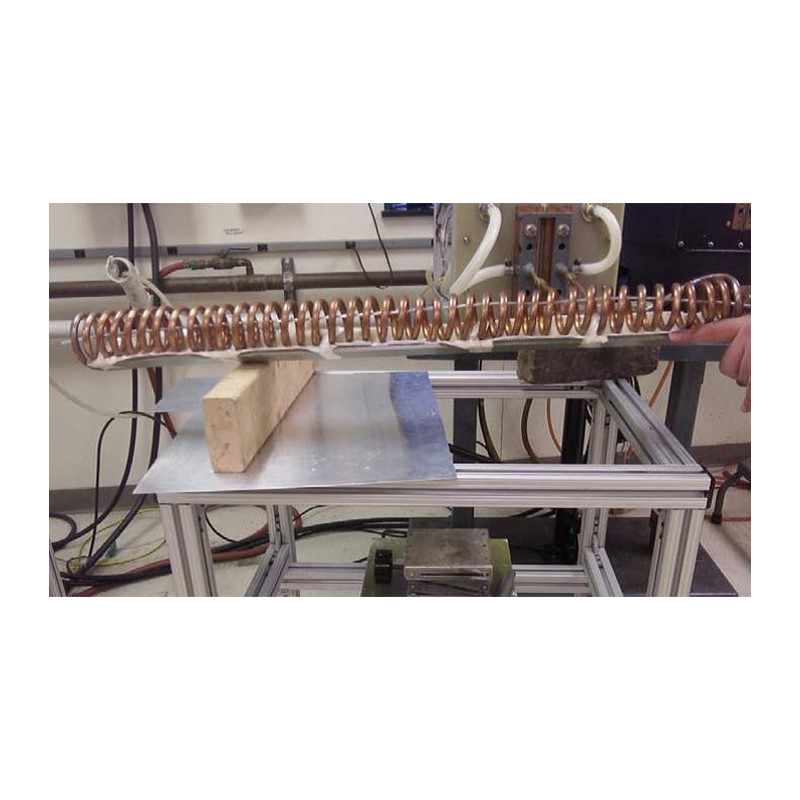

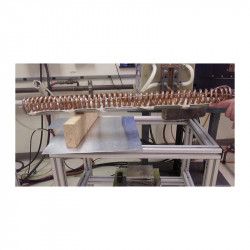

Objective: Heating the aluminum wire to achieve a temperature equal to that of the plastic coating applied to the wire

Material: Aluminum cable (diameter: 3.7 mm)

Temperature: 232 ºC

Frequency: 18 kHz

System: Ambrell EKOHEAT 50kW Induction heating system, 15-45 kHz with remote head, inductor consisting of 40 coils (length 0.8 m)

Process: It took 3 seconds to heat the wire to 232 ºC.

Results:

Да ли вас занима овај производ? Да ли су вам потребне додатне информације или појединачне цене?

морате бити пријављени

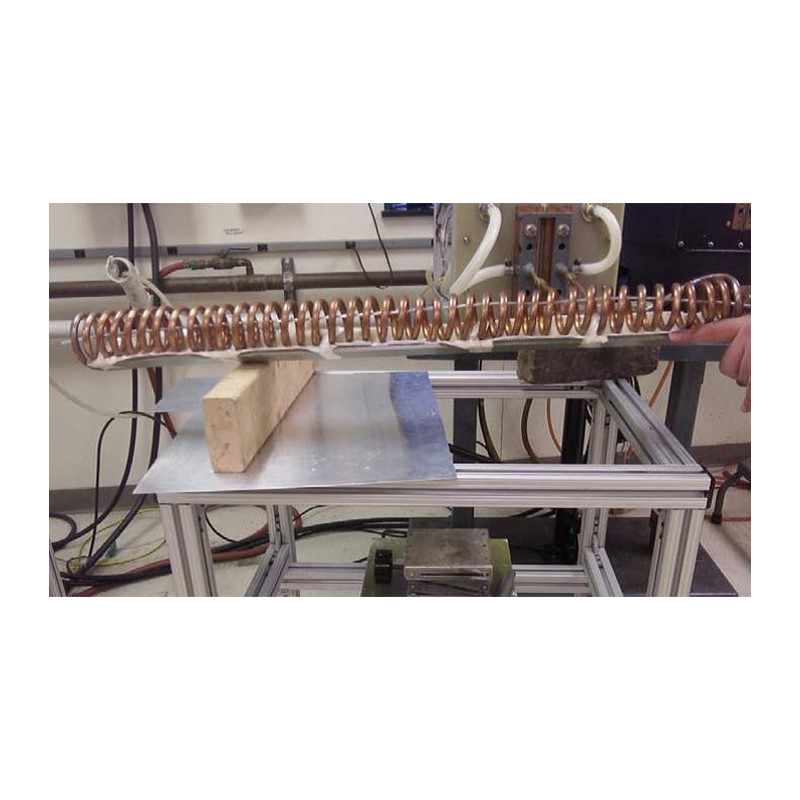

Objective: Heating the aluminum wire to achieve a temperature equal to that of the plastic coating applied to the wire

Material: Aluminum cable (diameter: 3.7 mm)

Temperature: 232 ºC

Frequency: 18 kHz

System: Ambrell EKOHEAT 50kW Induction heating system, 15-45 kHz with remote head, inductor consisting of 40 coils (length 0.8 m)

Process: It took 3 seconds to heat the wire to 232 ºC.

Results:

Vaša zahvalnost na komentar ne može biti registrovana

Prijavite nepristojan komentar

Prija nepristojnog komentara registrovana

Vaša prijava nepristojnog komentara ne može biti registrovana

Write your review

Komentar poslat

Vaš komentar ne može biti registrovan