Морате бити пријављени да

Category

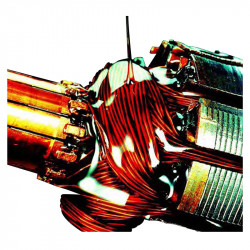

Фотографије су само у информативне сврхе. Погледајте спецификацију производа

please use latin characters

Application:

- electro-technical equipment.

- transformers,

- hermetic motors.

Impregnation:

By immersion, by atmosphere pressure.

It is recommended to use impregnation cylindrical ladle from stainless steel or plastic mass. For exemple: for lacquer WE 203-70 , obtain viscosity 30 s ±10 s by adding 200g of water and 100g of lacquer.

Water should be added progressively, and lacquer should be mechanically mixed.

Polymerisation:

- Preliminary heat up of the elements up to 60°C

- Immerse element until air bulbs stop showing.

- Rise temperature up to 95°C and stabilise.

- drying:3 - 4 hours @ 150°C or 1,3 hours. @ 180°C.

Storage requirements:

4 months in original and closed package, far away from the sun and heat source.

Packing:

Containers 1, 5 and 30l. or barrels 200 l.

Hygiene and protection

Lacquer is not toxic, delivered without label.

| Characteristic | Standards | WE 203-50 | WE 203-70 |

|---|---|---|---|

| Chemical origins | Alkyd modified | Alkyd modified | |

| Thermal class | F155°C | F155°C | |

| pseudo-viscosity @ 23°C CPE 6 | ISO 2431 | 35 s ±5 s | 240 s ±40 s |

| density @20°C | NFT30020 | 1,06 | 1,08 |

| Ignition point - crucible closed | NFT30050 | 52°C | 44°C |

| Dry extract | NSEG 00001 | 70% ±2% | 70% ±2% |

| Colour | natural | natural | |

| Drying on a plate | NSEG | @150°C 20 min | @ 150°C 20min |

| Diluent | water | water | |

| polymerisation | 3 + 4 h @150°C | 3 + 4 h @150°C | |

| polymerisation | 1 + 1,5 h @180°C | 1 + 1,5 h @180°C | |

| pH | 8,5 ±1 | 8,5 ±1 |

Да ли вас занима овај производ? Да ли су вам потребне додатне информације или појединачне цене?

морате бити пријављени

Application:

- electro-technical equipment.

- transformers,

- hermetic motors.

Impregnation:

By immersion, by atmosphere pressure.

It is recommended to use impregnation cylindrical ladle from stainless steel or plastic mass. For exemple: for lacquer WE 203-70 , obtain viscosity 30 s ±10 s by adding 200g of water and 100g of lacquer.

Water should be added progressively, and lacquer should be mechanically mixed.

Polymerisation:

- Preliminary heat up of the elements up to 60°C

- Immerse element until air bulbs stop showing.

- Rise temperature up to 95°C and stabilise.

- drying:3 - 4 hours @ 150°C or 1,3 hours. @ 180°C.

Storage requirements:

4 months in original and closed package, far away from the sun and heat source.

Packing:

Containers 1, 5 and 30l. or barrels 200 l.

Hygiene and protection

Lacquer is not toxic, delivered without label.

| Characteristic | Standards | WE 203-50 | WE 203-70 |

|---|---|---|---|

| Chemical origins | Alkyd modified | Alkyd modified | |

| Thermal class | F155°C | F155°C | |

| pseudo-viscosity @ 23°C CPE 6 | ISO 2431 | 35 s ±5 s | 240 s ±40 s |

| density @20°C | NFT30020 | 1,06 | 1,08 |

| Ignition point - crucible closed | NFT30050 | 52°C | 44°C |

| Dry extract | NSEG 00001 | 70% ±2% | 70% ±2% |

| Colour | natural | natural | |

| Drying on a plate | NSEG | @150°C 20 min | @ 150°C 20min |

| Diluent | water | water | |

| polymerisation | 3 + 4 h @150°C | 3 + 4 h @150°C | |

| polymerisation | 1 + 1,5 h @180°C | 1 + 1,5 h @180°C | |

| pH | 8,5 ±1 | 8,5 ±1 |

Vaša zahvalnost na komentar ne može biti registrovana

Prijavite nepristojan komentar

Prija nepristojnog komentara registrovana

Vaša prijava nepristojnog komentara ne može biti registrovana

Napišite vaš komentar

Komentar poslat

Vaš komentar ne može biti registrovan