Морате бити пријављени да

Category

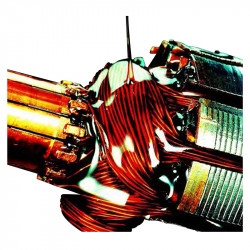

Фотографије су само у информативне сврхе. Погледајте спецификацију производа

please use latin characters

Material is one component, for electrical insulation class F 155°C dry in drier.

Application:

- electro technical material class B and F,

Main preferences:

- impregnation lacquer made from modified alkyd - epoxide resin, great dielectric withstand and elastic preferences.

- it is resistant for humidity and transformer oils.

- it is compatible with cables in enamel class B, F and H,

- E521 T (tropical version) meets requirements 41514 NFX.

Material impregnation:

-By immersion, or vacuum. Its good stability allows to impregnate electrical devices, which are hot. However, it cannot be generalised to all motor types.

-lacquer hardens when polymerisation occurs without any oxidation. It is recommended to check if the diluent is removed when the drying begins.

Polymerisation :

- preliminary component drying (40 4 50°C max.),

- immersion unit air blisters disappear

- drying depends on the weight of impregnated material.

- rise temperature up to 130°C,

- drying:

class B: 4 hours in temp. 130 4 140°C,

class F: 4 hours in temp. 150 4 160°C,

- Dry time can be changed according to the component weight,

Storage conditions:

12 months in original and closed package, far away from the sun and heat source

Packing:

-containers 1, 5 , 30 l or barrels 200 l.

Hygiene and protection:

Lacquer consists ksylen.

| Lacquer | Standard | E521TE521AT | E 521 ATX |

|---|---|---|---|

| Chemical origins | modified alkyd - epoxide | modified alkyd - epoxide | |

| Thermal class | (F)/155°C | (F)/155°C | |

| viscosity | ISO 2431 | 40s +/-10s | 40s+/-10s |

| density @ 20°C | NFT30020 | 0,98 | 0,98 |

| Ignition point - crucible closed | NFT30020 | 26°C | 26°C |

| Dry extract | NSEG 0001 | 45% +/- 2 | 45% +/- 2 |

| Colour | Orange | Pomarańczowy | |

| Drying on a plate | NSEG 0002w150°C2 | @ 150°C 2 h | w 150°C45 min. |

| Diluent | 37022 | 37022 |

Preferences:

| Breakdown on a copper plate [thickness 0,01 mm] | Volt |

|---|---|

| natural state | 1400 |

| After 8 days in humid air: | 1250 |

| After 8 days in destilated water: | 1200 |

| After 8 days in oil: | 1430 |

Да ли вас занима овај производ? Да ли су вам потребне додатне информације или појединачне цене?

морате бити пријављени

Material is one component, for electrical insulation class F 155°C dry in drier.

Application:

- electro technical material class B and F,

Main preferences:

- impregnation lacquer made from modified alkyd - epoxide resin, great dielectric withstand and elastic preferences.

- it is resistant for humidity and transformer oils.

- it is compatible with cables in enamel class B, F and H,

- E521 T (tropical version) meets requirements 41514 NFX.

Material impregnation:

-By immersion, or vacuum. Its good stability allows to impregnate electrical devices, which are hot. However, it cannot be generalised to all motor types.

-lacquer hardens when polymerisation occurs without any oxidation. It is recommended to check if the diluent is removed when the drying begins.

Polymerisation :

- preliminary component drying (40 4 50°C max.),

- immersion unit air blisters disappear

- drying depends on the weight of impregnated material.

- rise temperature up to 130°C,

- drying:

class B: 4 hours in temp. 130 4 140°C,

class F: 4 hours in temp. 150 4 160°C,

- Dry time can be changed according to the component weight,

Storage conditions:

12 months in original and closed package, far away from the sun and heat source

Packing:

-containers 1, 5 , 30 l or barrels 200 l.

Hygiene and protection:

Lacquer consists ksylen.

| Lacquer | Standard | E521TE521AT | E 521 ATX |

|---|---|---|---|

| Chemical origins | modified alkyd - epoxide | modified alkyd - epoxide | |

| Thermal class | (F)/155°C | (F)/155°C | |

| viscosity | ISO 2431 | 40s +/-10s | 40s+/-10s |

| density @ 20°C | NFT30020 | 0,98 | 0,98 |

| Ignition point - crucible closed | NFT30020 | 26°C | 26°C |

| Dry extract | NSEG 0001 | 45% +/- 2 | 45% +/- 2 |

| Colour | Orange | Pomarańczowy | |

| Drying on a plate | NSEG 0002w150°C2 | @ 150°C 2 h | w 150°C45 min. |

| Diluent | 37022 | 37022 |

Preferences:

| Breakdown on a copper plate [thickness 0,01 mm] | Volt |

|---|---|

| natural state | 1400 |

| After 8 days in humid air: | 1250 |

| After 8 days in destilated water: | 1200 |

| After 8 days in oil: | 1430 |

Vaša zahvalnost na komentar ne može biti registrovana

Prijavite nepristojan komentar

Prija nepristojnog komentara registrovana

Vaša prijava nepristojnog komentara ne može biti registrovana

Napišite vaš komentar

Komentar poslat

Vaš komentar ne može biti registrovan