Морате бити пријављени да

Category

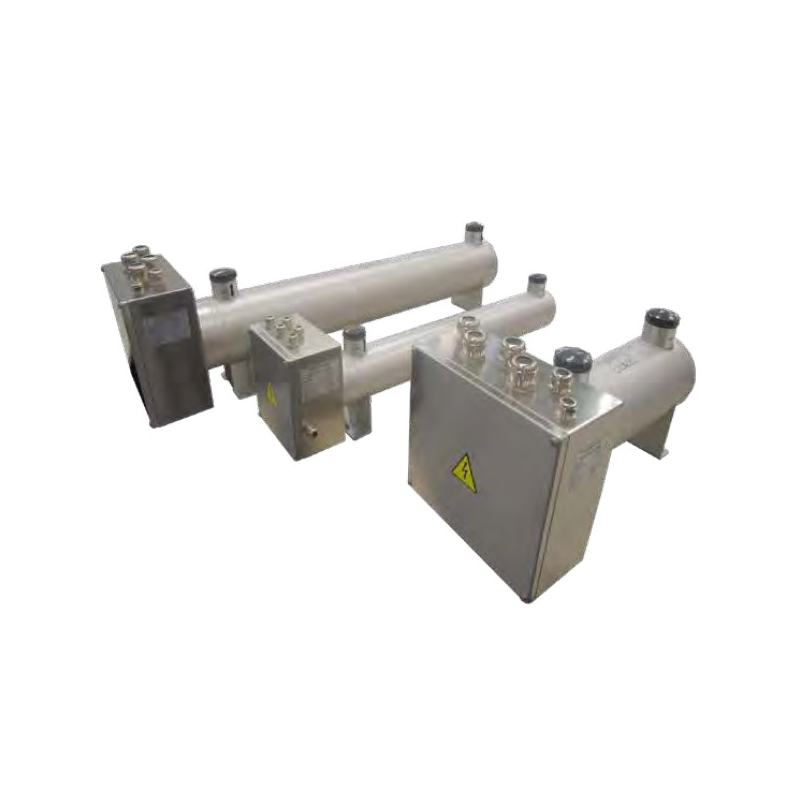

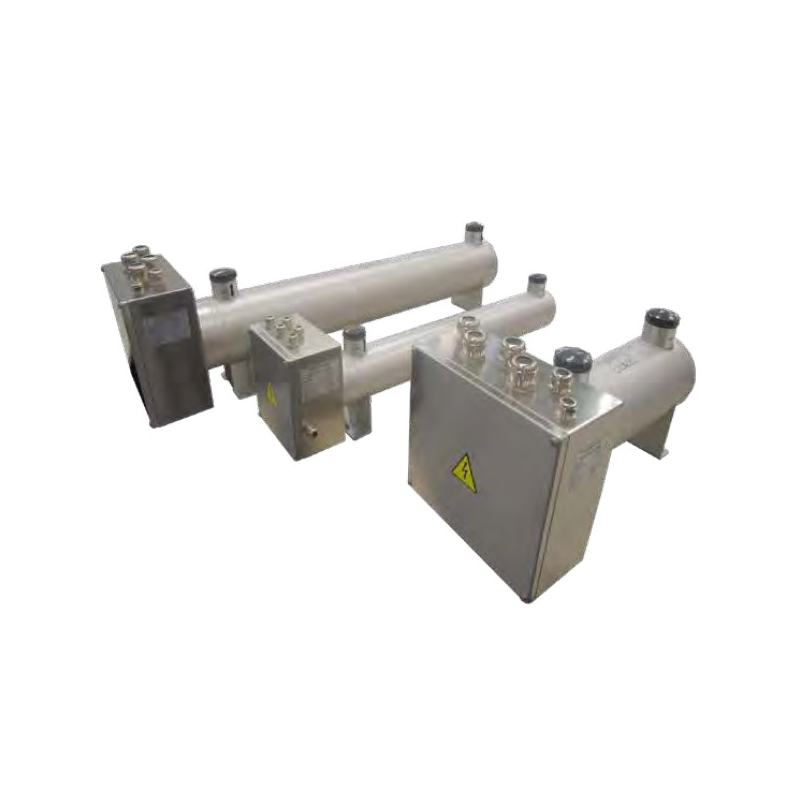

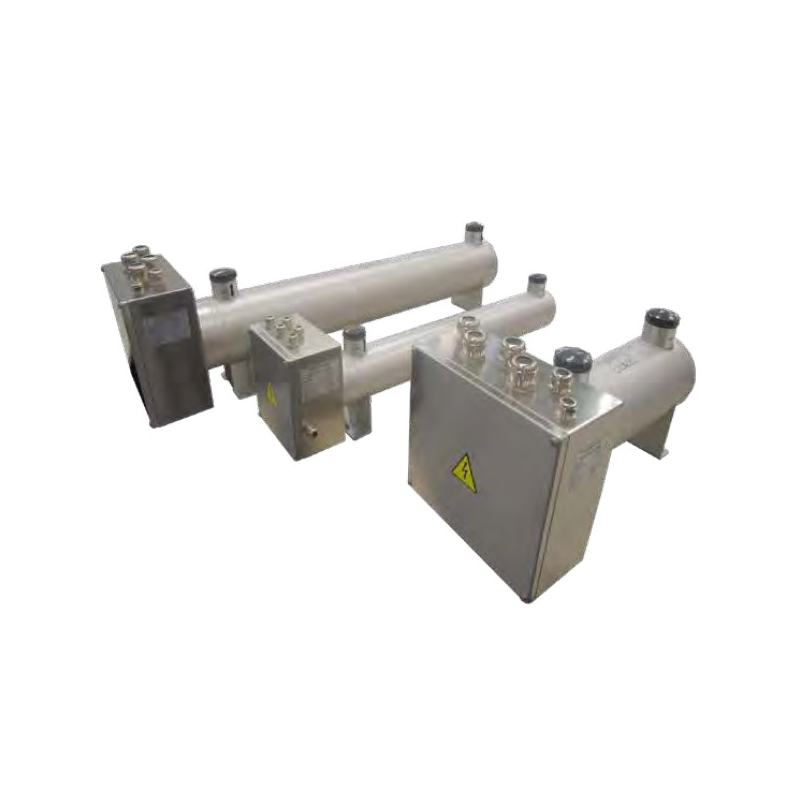

Фотографије су само у информативне сврхе. Погледајте спецификацију производа

please use latin characters

| Type | Power | Operating Voltage | Protection Level | Cooling |

|---|---|---|---|---|

| WHDN | 40 - 1,450 kW | 1kVAC / 1.4 kVDC | IP65/IP66 | Liquid |

| WHHB | 5 - 25 kW | 4.7 kVAC / 6.6 kVDC | IP00/IP65 | Liquid |

| WHBS | 6 - 100 kW | 1kVAC / 1.4 kVDC | IP00/IP66 | Liquid |

| WHB | 6 - 23 kW | 1kVAC / 1.4 kVDC | IP00/IP65 | Liquid |

| HVB | 0.6 – 1.2 kW | 4.5 kVAC / 6.41kVDC | IP65 | Air |

| HVBW | 0.6 – 1.2 kW | 4.5 kVAC / 6.41kVDC | IP65 | Air |

| TRV | 50 - 275 kW | 1kVAC / 1.4 kVDC | IP65/IP66 | Forced air |

| GxxRT | 3 - 32 kW | 1kVAC / 1.4 kVDC | IP65/IP66 | Air |

Fully welded, steel tank WHDN resistors are offered with tanks ranging in diameter from 100mm to 300mm.

A single resistor consists of steel elements with a diameter of 16mm, which are welded to a ring that is positioned within the tank. Different alloys can be used for the resistor elements, tank, and also the junction box. The resistor is positioned within the ring and sealed with a gasket. This design enables the resistor to be opened and the tank to be cleaned from the inside.

The electrical connection can be single, star/delta, or multiple. Inside the junction box, there are main terminals and auxiliary circuits, such as junction box heating, thermal protection circuits, and air bubble detection.

The resistor can be equipped with drainage, closing, or pressure relief valves. The standard mounting position is horizontal, but vertical mounting options are also possible (with height limitations).

| Rated Power | 40 kW - 1450 kW | |

|---|---|---|

| Operating Voltage | 1000 VAC / 1400 VDC | |

| Dielectric Strength at 5 Hz 1 min | 3,500 VAC | |

| Insulation Resistance at 5000 VDC | Dry Conditions | > 20 MΩ |

| Overload at One-Second Pulse per Hour | 8 x Pn (depends on Ω value) | |

| Overload at Five-Second Pulse per Hour | 4 x Pn (depends on Ω value) | |

| Resistance Tolerance | Standard | ± 10% |

| Optional | ± 5% / ± 3% | |

| Temperature Coefficient | 20 °C - 400 °C | 100 ppm/K |

| Resistor Heating Time Constant | 30 s | |

| Protection Level | IP65 / IP66 | |

| Cooling Liquid | Water/water-glycol | |

| Maximum Inlet Coolant Temperature | No Value Loss | * 60 °C |

| ∆T Input/Output (Recommended) | 10 K - 20 K | |

| Pressure Drop at Pn and ∆20K | 0.3 bar | |

| Materials | ||

| Container | Standard | AISI 304 |

| Optional | AISI 316 | |

| Junction Box | Standard | AISI 304 |

| Optional | AISI 316 | |

| Resistance Elements | Standard | AISI 304 |

| Optional | AISI 316 & 321, incoloy800 &825 | |

| Choke | Standard | Plate without holes |

| Optional | Nickel-plated brass/ AISI 304 | |

| Installation, Maintenance, and Storage Instructions | Available document | |

| Water Temperature Protection | Thermostat | |

| -Range (recommended 10K + Outlet water temperature) | 0 °C - 150 °C | |

| -Contact | Variable contact | |

| -Maximum Current | 16 A | |

| Air Bubble Protection | Thermostat | |

| -Range (recommended 180°C) | 50 °C - 300 °C | |

| -Contact | Variable contact | |

| -Maximum Current | 16 A | |

| Moisture Protection | Heating Cable 20-30W 230V | |

| -Voltage | Optional | 115 V |

| Factory Approval Tests | Setting/Dimension Inspection | |

| Resistance Value | ||

| Insulation Resistance | ||

| Dieletric Strength | ||

| Pressure Test | ||

| Optional | Certified Whole Test | |

| PT100 + Transducer | Optional | |

| Pressure Sensor 4-20mA | Optional |

* Depends on cooling fluid pressure and additives

Aluminum-cased WHBH resistors have high operating voltage. The active resistor wire has direct contact with the cooling fluid and must be cooled with demineralized water with or without glycol. Water input and output are located on the back side, opposite to the electrical connections.

Fully welded WHBH 16 resistor can have 3 or 6 steel tubes with a diameter of 16mm, welded to a steel tank. The water input and output can be on the top or on the back of the resistor. The connection can be open style with M6 threaded rods, IP00, or the resistor can be equipped with a junction box IP65/IP66.

Fully welded WHBH 32.4 resistor has mica-insulated elements. It has high operating voltage. Water output and input are located on the back side.

All fully welded resistors have undergone a pressure test of 12 psi according to EN 13445.

Resistor WHB 16.3 has an aluminum casing with seals. It has three tubular resistor elements and can be with or without a junction box. Water output and input are located on the back side.

HVB resistors are aluminum-cased resistors for applications with high energy surges. They have high operating voltage. The resistor is insulated and filled with sand (SiO) or magnesium oxide (MgO) to withstand energy surges.

| Rated Power | Standard | 25 kW |

|---|---|---|

| Operating Voltage | 4.7 kVAC / 6.6 kVDC | |

| Dielectric Strength at 50 Hz for 1 min | 20 kVAC | |

| Resistance Tolerance 5000 VDC | ± 10% | |

| ± 5% | ||

| Maximum Current | 160 A | |

| 500 A | ||

| Protection Degree | IP00 / IP65 | |

| Coolant | Demineralized water or Demineralized water/glycol | |

| -fluid conductivity | ≤ 2 µS/cm | |

| -maximum inlet coolant temperature | * 60 °C | |

| -ΔT inlet/outlet (recommended) | ≤15 K | |

| -pressure drop at 30L/min | ≤ 0.5 bar | |

| Materials | ||

| -housing (non-contact with fluid) | Anodized aluminum | |

| -resistive elements | Nickel-chrome alloy | |

| Operating Pressure | 6 bars at 55 °C | |

| Test Pressure | 10 bars at 20°C |

* Depends on the coolant pressure and additives

| Rated Power | 6 kW - 200 kW | |

|---|---|---|

| Operating Voltage | 1000 VAC / 1400 VDC | |

| Dielectric Strength at 50 Hz for 1 min | 3,500 VAC | |

| Insulation Resistance at 5000 VDC | Dry conditions | > 20 MΩ |

| Overload for one-second pulse per hour | 8 x Pn (depends on Ω value) | |

| Overload for five-second pulse per hour | 4 x Pn (depends on Ω value) | |

| Resistance Tolerance | Standard | ± 10% |

| Optional | ± 5% / ± 3% | |

| Temperature Coefficient | 20 °C - 400 °C | 100 ppm/K |

| Resistance Heating Time Constant | 30 s | |

| Protection Degree | IP00 / IP65 / IP66 | |

| Maximum Inlet Coolant Temperature | * 60 °C | |

| ΔT Inlet/Outlet (recommended) | 10 - 20 K | |

| Operating Pressure | 6 bars at 55 °C | |

| Test Pressure | 12 bars at 20 °C | |

| According to EN 13445 | 16 bars at 20 °C | |

| Coolant | Water/water-glycol | |

| Materials | ||

| Tank | Standard | AISI 304 |

| Optional | AISI 316 | |

| Terminal Box | Standard | AISI 304 |

| Optional | AISI 316 | |

| Resistive Elements | Standard | AISI 304 |

| Optional | AISI 316 & 321, incoloy800 &825 | |

| Drain/Air Vent | Optional | |

| Temperature Protection | Standard | Thermostat |

| -normally closed | 16 A at 230 VAC | |

| PT100 Temperature Sensor | Optional | |

| Air Bubble Protection | Optional | Thermostat |

| Moisture Protection | Optional | Heating Cable 15-30W |

| -voltage | optional | 115 V or 230 V |

* Depends on the coolant pressure and additives

| Rated Power | 3 kW - 6 kW | |

|---|---|---|

| Operating Voltage | 1000 VAC - 3000 VAC | |

| Dielectric Strength at 50Hz for 1 min | 10 kVAC | |

| Insulation Resistance at 5000 VDC | Dry conditions | >> 20 MΩ |

| Overload for one-second pulse per hour | 20 x Pn (depends on Ω value) | |

| Overload for five-second pulse per hour | 10 x Pn (depends on Ω value) | |

| Resistance Tolerance | Standard | ± 10% |

| Optional | ± 5% / ± 3% | |

| Resistance Heating Time Constant | 60 s | |

| Protection Degree | IP00 | |

| Maximum Inlet Coolant Temperature | * 60 °C | |

| ΔT Inlet/Outlet (recommended) | 10 - 20 K | |

| Operating Pressure | 6 bars at 55 °C | |

| Test Pressure | 12 bars at 20 °C | |

| According to EN 13445 | 16 bars at 20 °C | |

| Pressure Drop at 9L/min | 0.5 bar | |

| Coolant | Water/water-glycol | |

| Material (fully welded tank) | Standard | AIS 304 |

* Depends on the coolant pressure and additives

| Rated Power | 6 kW - 23 kW | |

|---|---|---|

| Operating Voltage | 1000 VAC / 1400 VDC | |

| Dielectric Strength at 50Hz for 1 min | 3,500 VAC | |

| Insulation Resistance at 5000 VDC | Dry conditions | > 20 MΩ |

| Overload for one-second pulse per hour | 8 x Pn (depends on Ω value) | |

| Overload for five-second pulse per hour | 4 x Pn (depends on Ω value) | |

| Resistance Tolerance | Standard | ± 10% |

| Optional | ± 5% / ± 3% | |

| Temperature Coefficient | 20 °C - 400 °C | 100 ppm/K |

| Resistance Heating Time Constant | 30 s | |

| Maximum Inlet Coolant Temperature | * 60 °C | |

| ΔT Inlet/Outlet (recommended) | 10 - 20 K | |

| Operating Pressure | 6 bars at 55 °C | |

| Test Pressure | 10 bars at 20 °C | |

| According to EN 13445 | 11 bars at 20 °C | |

| Pressure Drop at 9L/min | 0.5 bar | |

| Cooling Connection | ¼" / ½" | |

| Enclosure Material | Anodized Aluminium | |

| - Junction Box | Optional | Aluminium |

| Energy Range 5s* | HVB 70.400.1 | 150 kJ – 285 kJ |

|---|---|---|

| HVB 70.400.2 | 300 kJ – 570 kJ | |

| Resistance Tolerance | ± 10% | |

| Temperature Coefficient | 100 ppm/K | |

| Operating Voltage | 4,500 VAC / 6,360 VDC | |

| Dielectric Strength at 50Hz for 1 min | 10 kV | |

| Insulation Resistance at 5000 VDC | Dry conditions | > 20 MΩ |

| Connection | Standard | Radox Cable 1000mm |

| Protection Degree | IP65 | |

| Cooling | Natural Air | |

| Enclosure Material | Anodized Aluminium |

*Depends on resistance

| Energy Range 5s* | HVBW 70.400.1 | 150 kJ – 285 kJ |

|---|---|---|

| HVBW 70.400.2 | 300 kJ – 570 kJ | |

| Resistance Tolerance | ± 10% | |

| Temperature Coefficient | 100 ppm/K | |

| Operating Voltage | 4,500 VAC / 6,360 VDC | |

| Dielectric Strength at 50Hz for 1 min | 10 kV | |

| Insulation Resistance at 5000 VDC | Dry conditions | > 20 MΩ |

| Connection | Standard | Radox Cable 1000mm |

| Protection Degree | IP65 | |

| Cooling | Natural Air | |

| Enclosure Material | Stainless Steel AISI 316L |

Steel tube resistors, actively cooled by air, have two or four powerful fans as active cooling. Tubes can be made from various alloys to match environmental conditions. The housing and junction box are offered in AISI304 and ASIS316. Inside the junction box are main terminals, cabin heater, and all secondary circuits. The protection degree is IP65 or IP66.

GxxRT are naturally cooled steel tube resistors. They can have three, nine, ten, or twelve tubes welded to the housing. The junction box contains main terminals and all auxiliary circuits. The protection degree is IP65. A protective grille is optional.

| Power Range | 50kW – 275kW | |

|---|---|---|

| Temperature Coefficient | 20 °C - 400 °C | 85 ppm/K |

| Operating Voltage | 1000 VAC / 1400 VDC | |

| Dielectric Strength at 50 Hz for 1 min | 3,500 VAC | |

| Insulation Resistance at 5000 VDC | Dry conditions | >> 10 MΩ |

| Overload at 5-second pulse per hour | 7 x Pn (depends on Ω value) | |

| Overload at 10-second pulse per hour | 5 x Pn (depends on Ω value) | |

| Resistance Tolerance | standard | ± 10% |

| optional | ± 5% / ± 3% | |

| Electrical Circuit Connection | standard | Single Resistor Unit |

| optional | Star/Delta/Separation | |

| Environmental Conditions | Temperature Range | -20 °C - 40 °C |

| Altitude | 1000m | |

| Resistance Heating Time Constant | 60 s | |

| Protection Degree | IP65/IP66 | |

| Fans | Standard Voltage | 415 V, 3-phase, 50 Hz |

| Optional Voltage | 430 V, 3-phase, 60 Hz | |

| Power | 1.5 kW per motor | |

| Protection Degree | IP66 | |

| Air Flow | 5000 m3/h per motor | |

| Motor | Steel | |

| Air Inlet/Outlet ΔT | ≈ 50 K | |

| Materials | ||

| -Brackets/Panels | Standard | AISI 304 |

| optional | AISI 316L | |

| -Junction Box | Standard | AISI 304 |

| optional | AISI 316L | |

| -Resistance Elements | Standard | AISI 321 |

| optional | AISI 304, AISI 316L, incoloy800 and 825 | |

| -Choke | Standard | Nickel-Plated Brass/ AISI 304 |

| optional | Plate without holes | |

| Moisture Protection | Heating Wire 100-120W 230V | |

| -Voltage | Optional | 115 V |

| Factory Approval Tests | Setting/Dimension Inspection | |

| Resistance Value | ||

| Insulation Resistance | ||

| Dielectric Strength | ||

| Optional | Certified Whole Test |

| Power Range | 3kW – 32kW | |

|---|---|---|

| Operating Voltage | 1000 VAC / 1400 VDC | |

| Dielectric Strength at 50 Hz for 1 min | 3,500 VAC | |

| Insulation Resistance at 5000 VDC | Dry conditions | > 20 MΩ |

| Overload at 5-second pulse per hour | 10 x Pn (depends on Ω value) | |

| Overload at 10-second pulse per hour | 7 x Pn (depends on Ω value) | |

| Resistance Tolerance | standard | ± 10% |

| Optional | ± 5% / ± 3% | |

| Temperature Coefficient | 20 °C - 400 °C | 100 ppm/K |

| Resistance Heating Time Constant | ||

| Protection Degree | IP65 | |

| Cooling | Natural Air | |

| Configuration | Standard | Single Phase |

| Optional | Star/Delta 3-phase | |

| Optional | Multi-segment | |

| Thermal Protection | Standard | Thermal Switch |

| -Normally Closed Connection | 2 A at 250 VAC, 50 Hz, cos 0.95 | |

| Moisture Protection | Heating Wire 100-120W 230V | |

| -Voltage | Optional | 115 V |

| Mechanical Protection from Direct Contact with Hot Elements | Optional | Protective Grid |

| Materials | ||

| -Housing | Standard | AISI 304 |

| Optional | AISI 316 | |

| -Junction Box | Standard | AISI 304 |

| Optional | AISI 316 | |

| -Resistance Elements | Standard | AISI 304 |

| Optional | AISI 304, AISI 316L, incoloy800 and 825 | |

| Factory Approval Tests | Setting/Dimension Inspection | |

| Resistance Value | ||

| Insulation Resistance | ||

| Dielectric Strength |

Да ли вас занима овај производ? Да ли су вам потребне додатне информације или појединачне цене?

морате бити пријављени

| Type | Power | Operating Voltage | Protection Level | Cooling |

|---|---|---|---|---|

| WHDN | 40 - 1,450 kW | 1kVAC / 1.4 kVDC | IP65/IP66 | Liquid |

| WHHB | 5 - 25 kW | 4.7 kVAC / 6.6 kVDC | IP00/IP65 | Liquid |

| WHBS | 6 - 100 kW | 1kVAC / 1.4 kVDC | IP00/IP66 | Liquid |

| WHB | 6 - 23 kW | 1kVAC / 1.4 kVDC | IP00/IP65 | Liquid |

| HVB | 0.6 – 1.2 kW | 4.5 kVAC / 6.41kVDC | IP65 | Air |

| HVBW | 0.6 – 1.2 kW | 4.5 kVAC / 6.41kVDC | IP65 | Air |

| TRV | 50 - 275 kW | 1kVAC / 1.4 kVDC | IP65/IP66 | Forced air |

| GxxRT | 3 - 32 kW | 1kVAC / 1.4 kVDC | IP65/IP66 | Air |

Fully welded, steel tank WHDN resistors are offered with tanks ranging in diameter from 100mm to 300mm.

A single resistor consists of steel elements with a diameter of 16mm, which are welded to a ring that is positioned within the tank. Different alloys can be used for the resistor elements, tank, and also the junction box. The resistor is positioned within the ring and sealed with a gasket. This design enables the resistor to be opened and the tank to be cleaned from the inside.

The electrical connection can be single, star/delta, or multiple. Inside the junction box, there are main terminals and auxiliary circuits, such as junction box heating, thermal protection circuits, and air bubble detection.

The resistor can be equipped with drainage, closing, or pressure relief valves. The standard mounting position is horizontal, but vertical mounting options are also possible (with height limitations).

| Rated Power | 40 kW - 1450 kW | |

|---|---|---|

| Operating Voltage | 1000 VAC / 1400 VDC | |

| Dielectric Strength at 5 Hz 1 min | 3,500 VAC | |

| Insulation Resistance at 5000 VDC | Dry Conditions | > 20 MΩ |

| Overload at One-Second Pulse per Hour | 8 x Pn (depends on Ω value) | |

| Overload at Five-Second Pulse per Hour | 4 x Pn (depends on Ω value) | |

| Resistance Tolerance | Standard | ± 10% |

| Optional | ± 5% / ± 3% | |

| Temperature Coefficient | 20 °C - 400 °C | 100 ppm/K |

| Resistor Heating Time Constant | 30 s | |

| Protection Level | IP65 / IP66 | |

| Cooling Liquid | Water/water-glycol | |

| Maximum Inlet Coolant Temperature | No Value Loss | * 60 °C |

| ∆T Input/Output (Recommended) | 10 K - 20 K | |

| Pressure Drop at Pn and ∆20K | 0.3 bar | |

| Materials | ||

| Container | Standard | AISI 304 |

| Optional | AISI 316 | |

| Junction Box | Standard | AISI 304 |

| Optional | AISI 316 | |

| Resistance Elements | Standard | AISI 304 |

| Optional | AISI 316 & 321, incoloy800 &825 | |

| Choke | Standard | Plate without holes |

| Optional | Nickel-plated brass/ AISI 304 | |

| Installation, Maintenance, and Storage Instructions | Available document | |

| Water Temperature Protection | Thermostat | |

| -Range (recommended 10K + Outlet water temperature) | 0 °C - 150 °C | |

| -Contact | Variable contact | |

| -Maximum Current | 16 A | |

| Air Bubble Protection | Thermostat | |

| -Range (recommended 180°C) | 50 °C - 300 °C | |

| -Contact | Variable contact | |

| -Maximum Current | 16 A | |

| Moisture Protection | Heating Cable 20-30W 230V | |

| -Voltage | Optional | 115 V |

| Factory Approval Tests | Setting/Dimension Inspection | |

| Resistance Value | ||

| Insulation Resistance | ||

| Dieletric Strength | ||

| Pressure Test | ||

| Optional | Certified Whole Test | |

| PT100 + Transducer | Optional | |

| Pressure Sensor 4-20mA | Optional |

* Depends on cooling fluid pressure and additives

Aluminum-cased WHBH resistors have high operating voltage. The active resistor wire has direct contact with the cooling fluid and must be cooled with demineralized water with or without glycol. Water input and output are located on the back side, opposite to the electrical connections.

Fully welded WHBH 16 resistor can have 3 or 6 steel tubes with a diameter of 16mm, welded to a steel tank. The water input and output can be on the top or on the back of the resistor. The connection can be open style with M6 threaded rods, IP00, or the resistor can be equipped with a junction box IP65/IP66.

Fully welded WHBH 32.4 resistor has mica-insulated elements. It has high operating voltage. Water output and input are located on the back side.

All fully welded resistors have undergone a pressure test of 12 psi according to EN 13445.

Resistor WHB 16.3 has an aluminum casing with seals. It has three tubular resistor elements and can be with or without a junction box. Water output and input are located on the back side.

HVB resistors are aluminum-cased resistors for applications with high energy surges. They have high operating voltage. The resistor is insulated and filled with sand (SiO) or magnesium oxide (MgO) to withstand energy surges.

| Rated Power | Standard | 25 kW |

|---|---|---|

| Operating Voltage | 4.7 kVAC / 6.6 kVDC | |

| Dielectric Strength at 50 Hz for 1 min | 20 kVAC | |

| Resistance Tolerance 5000 VDC | ± 10% | |

| ± 5% | ||

| Maximum Current | 160 A | |

| 500 A | ||

| Protection Degree | IP00 / IP65 | |

| Coolant | Demineralized water or Demineralized water/glycol | |

| -fluid conductivity | ≤ 2 µS/cm | |

| -maximum inlet coolant temperature | * 60 °C | |

| -ΔT inlet/outlet (recommended) | ≤15 K | |

| -pressure drop at 30L/min | ≤ 0.5 bar | |

| Materials | ||

| -housing (non-contact with fluid) | Anodized aluminum | |

| -resistive elements | Nickel-chrome alloy | |

| Operating Pressure | 6 bars at 55 °C | |

| Test Pressure | 10 bars at 20°C |

* Depends on the coolant pressure and additives

| Rated Power | 6 kW - 200 kW | |

|---|---|---|

| Operating Voltage | 1000 VAC / 1400 VDC | |

| Dielectric Strength at 50 Hz for 1 min | 3,500 VAC | |

| Insulation Resistance at 5000 VDC | Dry conditions | > 20 MΩ |

| Overload for one-second pulse per hour | 8 x Pn (depends on Ω value) | |

| Overload for five-second pulse per hour | 4 x Pn (depends on Ω value) | |

| Resistance Tolerance | Standard | ± 10% |

| Optional | ± 5% / ± 3% | |

| Temperature Coefficient | 20 °C - 400 °C | 100 ppm/K |

| Resistance Heating Time Constant | 30 s | |

| Protection Degree | IP00 / IP65 / IP66 | |

| Maximum Inlet Coolant Temperature | * 60 °C | |

| ΔT Inlet/Outlet (recommended) | 10 - 20 K | |

| Operating Pressure | 6 bars at 55 °C | |

| Test Pressure | 12 bars at 20 °C | |

| According to EN 13445 | 16 bars at 20 °C | |

| Coolant | Water/water-glycol | |

| Materials | ||

| Tank | Standard | AISI 304 |

| Optional | AISI 316 | |

| Terminal Box | Standard | AISI 304 |

| Optional | AISI 316 | |

| Resistive Elements | Standard | AISI 304 |

| Optional | AISI 316 & 321, incoloy800 &825 | |

| Drain/Air Vent | Optional | |

| Temperature Protection | Standard | Thermostat |

| -normally closed | 16 A at 230 VAC | |

| PT100 Temperature Sensor | Optional | |

| Air Bubble Protection | Optional | Thermostat |

| Moisture Protection | Optional | Heating Cable 15-30W |

| -voltage | optional | 115 V or 230 V |

* Depends on the coolant pressure and additives

| Rated Power | 3 kW - 6 kW | |

|---|---|---|

| Operating Voltage | 1000 VAC - 3000 VAC | |

| Dielectric Strength at 50Hz for 1 min | 10 kVAC | |

| Insulation Resistance at 5000 VDC | Dry conditions | >> 20 MΩ |

| Overload for one-second pulse per hour | 20 x Pn (depends on Ω value) | |

| Overload for five-second pulse per hour | 10 x Pn (depends on Ω value) | |

| Resistance Tolerance | Standard | ± 10% |

| Optional | ± 5% / ± 3% | |

| Resistance Heating Time Constant | 60 s | |

| Protection Degree | IP00 | |

| Maximum Inlet Coolant Temperature | * 60 °C | |

| ΔT Inlet/Outlet (recommended) | 10 - 20 K | |

| Operating Pressure | 6 bars at 55 °C | |

| Test Pressure | 12 bars at 20 °C | |

| According to EN 13445 | 16 bars at 20 °C | |

| Pressure Drop at 9L/min | 0.5 bar | |

| Coolant | Water/water-glycol | |

| Material (fully welded tank) | Standard | AIS 304 |

* Depends on the coolant pressure and additives

| Rated Power | 6 kW - 23 kW | |

|---|---|---|

| Operating Voltage | 1000 VAC / 1400 VDC | |

| Dielectric Strength at 50Hz for 1 min | 3,500 VAC | |

| Insulation Resistance at 5000 VDC | Dry conditions | > 20 MΩ |

| Overload for one-second pulse per hour | 8 x Pn (depends on Ω value) | |

| Overload for five-second pulse per hour | 4 x Pn (depends on Ω value) | |

| Resistance Tolerance | Standard | ± 10% |

| Optional | ± 5% / ± 3% | |

| Temperature Coefficient | 20 °C - 400 °C | 100 ppm/K |

| Resistance Heating Time Constant | 30 s | |

| Maximum Inlet Coolant Temperature | * 60 °C | |

| ΔT Inlet/Outlet (recommended) | 10 - 20 K | |

| Operating Pressure | 6 bars at 55 °C | |

| Test Pressure | 10 bars at 20 °C | |

| According to EN 13445 | 11 bars at 20 °C | |

| Pressure Drop at 9L/min | 0.5 bar | |

| Cooling Connection | ¼" / ½" | |

| Enclosure Material | Anodized Aluminium | |

| - Junction Box | Optional | Aluminium |

| Energy Range 5s* | HVB 70.400.1 | 150 kJ – 285 kJ |

|---|---|---|

| HVB 70.400.2 | 300 kJ – 570 kJ | |

| Resistance Tolerance | ± 10% | |

| Temperature Coefficient | 100 ppm/K | |

| Operating Voltage | 4,500 VAC / 6,360 VDC | |

| Dielectric Strength at 50Hz for 1 min | 10 kV | |

| Insulation Resistance at 5000 VDC | Dry conditions | > 20 MΩ |

| Connection | Standard | Radox Cable 1000mm |

| Protection Degree | IP65 | |

| Cooling | Natural Air | |

| Enclosure Material | Anodized Aluminium |

*Depends on resistance

| Energy Range 5s* | HVBW 70.400.1 | 150 kJ – 285 kJ |

|---|---|---|

| HVBW 70.400.2 | 300 kJ – 570 kJ | |

| Resistance Tolerance | ± 10% | |

| Temperature Coefficient | 100 ppm/K | |

| Operating Voltage | 4,500 VAC / 6,360 VDC | |

| Dielectric Strength at 50Hz for 1 min | 10 kV | |

| Insulation Resistance at 5000 VDC | Dry conditions | > 20 MΩ |

| Connection | Standard | Radox Cable 1000mm |

| Protection Degree | IP65 | |

| Cooling | Natural Air | |

| Enclosure Material | Stainless Steel AISI 316L |

Steel tube resistors, actively cooled by air, have two or four powerful fans as active cooling. Tubes can be made from various alloys to match environmental conditions. The housing and junction box are offered in AISI304 and ASIS316. Inside the junction box are main terminals, cabin heater, and all secondary circuits. The protection degree is IP65 or IP66.

GxxRT are naturally cooled steel tube resistors. They can have three, nine, ten, or twelve tubes welded to the housing. The junction box contains main terminals and all auxiliary circuits. The protection degree is IP65. A protective grille is optional.

| Power Range | 50kW – 275kW | |

|---|---|---|

| Temperature Coefficient | 20 °C - 400 °C | 85 ppm/K |

| Operating Voltage | 1000 VAC / 1400 VDC | |

| Dielectric Strength at 50 Hz for 1 min | 3,500 VAC | |

| Insulation Resistance at 5000 VDC | Dry conditions | >> 10 MΩ |

| Overload at 5-second pulse per hour | 7 x Pn (depends on Ω value) | |

| Overload at 10-second pulse per hour | 5 x Pn (depends on Ω value) | |

| Resistance Tolerance | standard | ± 10% |

| optional | ± 5% / ± 3% | |

| Electrical Circuit Connection | standard | Single Resistor Unit |

| optional | Star/Delta/Separation | |

| Environmental Conditions | Temperature Range | -20 °C - 40 °C |

| Altitude | 1000m | |

| Resistance Heating Time Constant | 60 s | |

| Protection Degree | IP65/IP66 | |

| Fans | Standard Voltage | 415 V, 3-phase, 50 Hz |

| Optional Voltage | 430 V, 3-phase, 60 Hz | |

| Power | 1.5 kW per motor | |

| Protection Degree | IP66 | |

| Air Flow | 5000 m3/h per motor | |

| Motor | Steel | |

| Air Inlet/Outlet ΔT | ≈ 50 K | |

| Materials | ||

| -Brackets/Panels | Standard | AISI 304 |

| optional | AISI 316L | |

| -Junction Box | Standard | AISI 304 |

| optional | AISI 316L | |

| -Resistance Elements | Standard | AISI 321 |

| optional | AISI 304, AISI 316L, incoloy800 and 825 | |

| -Choke | Standard | Nickel-Plated Brass/ AISI 304 |

| optional | Plate without holes | |

| Moisture Protection | Heating Wire 100-120W 230V | |

| -Voltage | Optional | 115 V |

| Factory Approval Tests | Setting/Dimension Inspection | |

| Resistance Value | ||

| Insulation Resistance | ||

| Dielectric Strength | ||

| Optional | Certified Whole Test |

| Power Range | 3kW – 32kW | |

|---|---|---|

| Operating Voltage | 1000 VAC / 1400 VDC | |

| Dielectric Strength at 50 Hz for 1 min | 3,500 VAC | |

| Insulation Resistance at 5000 VDC | Dry conditions | > 20 MΩ |

| Overload at 5-second pulse per hour | 10 x Pn (depends on Ω value) | |

| Overload at 10-second pulse per hour | 7 x Pn (depends on Ω value) | |

| Resistance Tolerance | standard | ± 10% |

| Optional | ± 5% / ± 3% | |

| Temperature Coefficient | 20 °C - 400 °C | 100 ppm/K |

| Resistance Heating Time Constant | ||

| Protection Degree | IP65 | |

| Cooling | Natural Air | |

| Configuration | Standard | Single Phase |

| Optional | Star/Delta 3-phase | |

| Optional | Multi-segment | |

| Thermal Protection | Standard | Thermal Switch |

| -Normally Closed Connection | 2 A at 250 VAC, 50 Hz, cos 0.95 | |

| Moisture Protection | Heating Wire 100-120W 230V | |

| -Voltage | Optional | 115 V |

| Mechanical Protection from Direct Contact with Hot Elements | Optional | Protective Grid |

| Materials | ||

| -Housing | Standard | AISI 304 |

| Optional | AISI 316 | |

| -Junction Box | Standard | AISI 304 |

| Optional | AISI 316 | |

| -Resistance Elements | Standard | AISI 304 |

| Optional | AISI 304, AISI 316L, incoloy800 and 825 | |

| Factory Approval Tests | Setting/Dimension Inspection | |

| Resistance Value | ||

| Insulation Resistance | ||

| Dielectric Strength |

Vaša zahvalnost na komentar ne može biti registrovana

Prijavite nepristojan komentar

Prija nepristojnog komentara registrovana

Vaša prijava nepristojnog komentara ne može biti registrovana

Write your review

Komentar poslat

Vaš komentar ne može biti registrovan