Морате бити пријављени да

Category

Фотографије су само у информативне сврхе. Погледајте спецификацију производа

please use latin characters

The anti-extrusion rings, also known as back-up rings are used in dynamic or static sealing rods or pistons applications. Under high pressures they prevent the penetration (gap extrusion) of the sealing element (O-Ring or X-Ring) in the sealing gap.

In addition to improving the lifetime of an O-ring or a X-ring by protecting them from any impurities, the use of anti-extrusion rings widens their range of applications while remaining very cost effective in the following cases:

There are 3 standard profiles of back-up rings (BAE):

The profiles AEM and AEC are available in slotted design with an angle of 30 or 45°, or special version (20°) upon request.

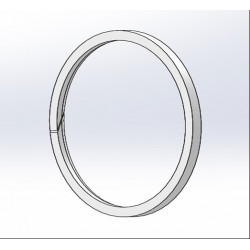

Back-up ring type AES

Back-up ring type AEM

Back-up ring type AEC

The recommendations are identical to those of the installation of the O-ring, however for the non cut back-up rings, the installation in closed grooves should be made with a special tool. The ring must be expanded with a cone and recalibrated after assembly.

| Base material | Type | Pressure | ||

|---|---|---|---|---|

| AES | AEM/F | AEC/F | Bars | |

| PTFE (Virgin) standard | X | X | X | 250 |

| PTFE Glassfibre-filled | X | X | 400 | |

| PTFE Carbon-filled | X | X | 400 | |

| PTFE Bronze-filled | X | 400 | ||

| NBR 90 SH | X | X | 200 | |

| FPM 90 SH | X | X | 200 | |

Да ли вас занима овај производ? Да ли су вам потребне додатне информације или појединачне цене?

морате бити пријављени

The anti-extrusion rings, also known as back-up rings are used in dynamic or static sealing rods or pistons applications. Under high pressures they prevent the penetration (gap extrusion) of the sealing element (O-Ring or X-Ring) in the sealing gap.

In addition to improving the lifetime of an O-ring or a X-ring by protecting them from any impurities, the use of anti-extrusion rings widens their range of applications while remaining very cost effective in the following cases:

There are 3 standard profiles of back-up rings (BAE):

The profiles AEM and AEC are available in slotted design with an angle of 30 or 45°, or special version (20°) upon request.

Back-up ring type AES

Back-up ring type AEM

Back-up ring type AEC

The recommendations are identical to those of the installation of the O-ring, however for the non cut back-up rings, the installation in closed grooves should be made with a special tool. The ring must be expanded with a cone and recalibrated after assembly.

| Base material | Type | Pressure | ||

|---|---|---|---|---|

| AES | AEM/F | AEC/F | Bars | |

| PTFE (Virgin) standard | X | X | X | 250 |

| PTFE Glassfibre-filled | X | X | 400 | |

| PTFE Carbon-filled | X | X | 400 | |

| PTFE Bronze-filled | X | 400 | ||

| NBR 90 SH | X | X | 200 | |

| FPM 90 SH | X | X | 200 | |

Vaša zahvalnost na komentar ne može biti registrovana

Prijavite nepristojan komentar

Prija nepristojnog komentara registrovana

Vaša prijava nepristojnog komentara ne može biti registrovana

Napišite vaš komentar

Komentar poslat

Vaš komentar ne može biti registrovan