Ви повинні увійти в систему

Category

Фотографії призначені тільки для інформаційних цілей. Подивитися специфікацію продукту

please use latin characters

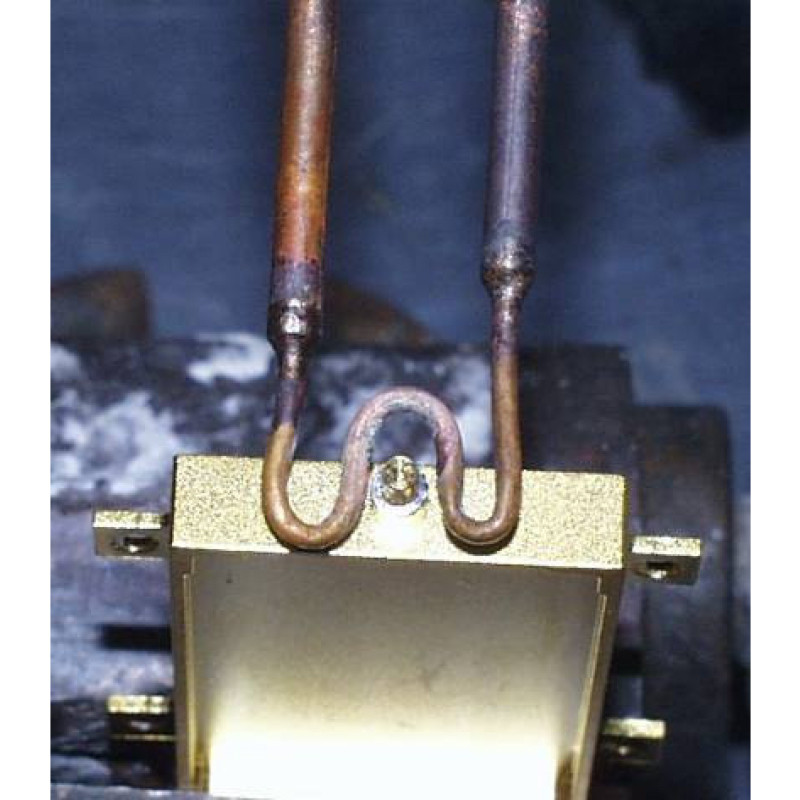

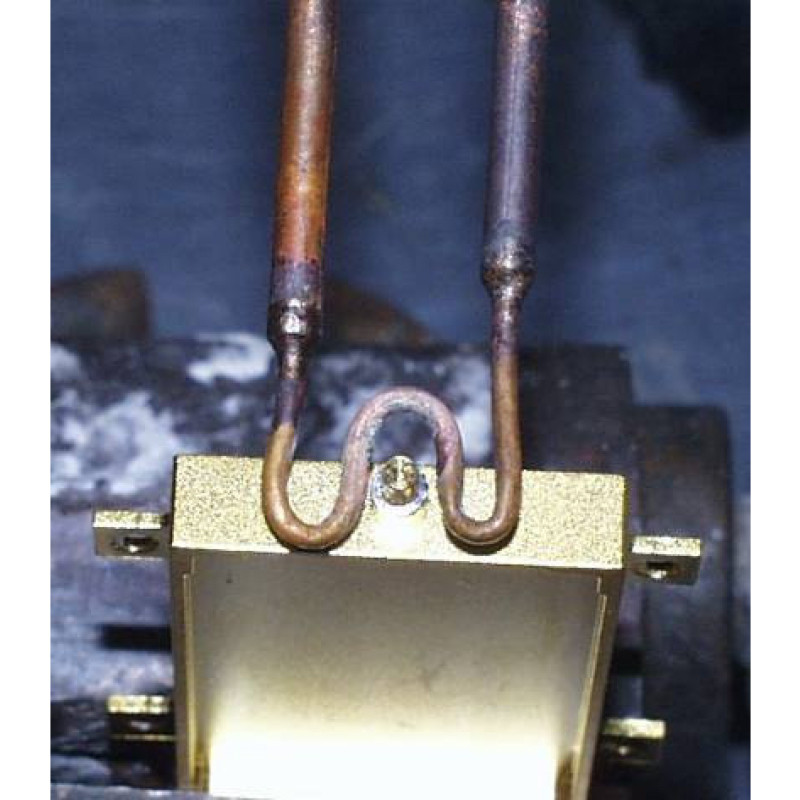

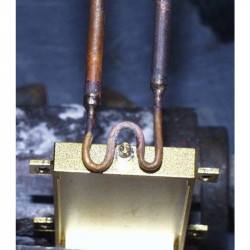

Objective: Soldering a fiber optics cable in a ferrule to form a hermetic seal.

Frequency: 346 kHz

Material: Panda PM fiber 0.0098” (.25mm) dia, kovar ferrule 0.086” (2.2mm) dia and metal enclosure 1.96” x 1.06” x 0.23” thick (50mm x 27mm x 5.9mm thick), solder preforms and flux

Temperature: 450 ºF (232 ºC)

A single turn channel “C” coil is used for this soldering application. Assembly is fluxed at the joint area and power is applied for 15 seconds to create the hermetic seal in the ferrule. The customer chose our solution due to the ability to design the single channel “C” coil. The coil heats quickly so that the heat does not travel to heat sensitive components in the case.

Ви зацікавлені у цьому продукті? Вам потрібна додаткова інформація або індивідуальні розцінки?

Ви повинні увійти в систему

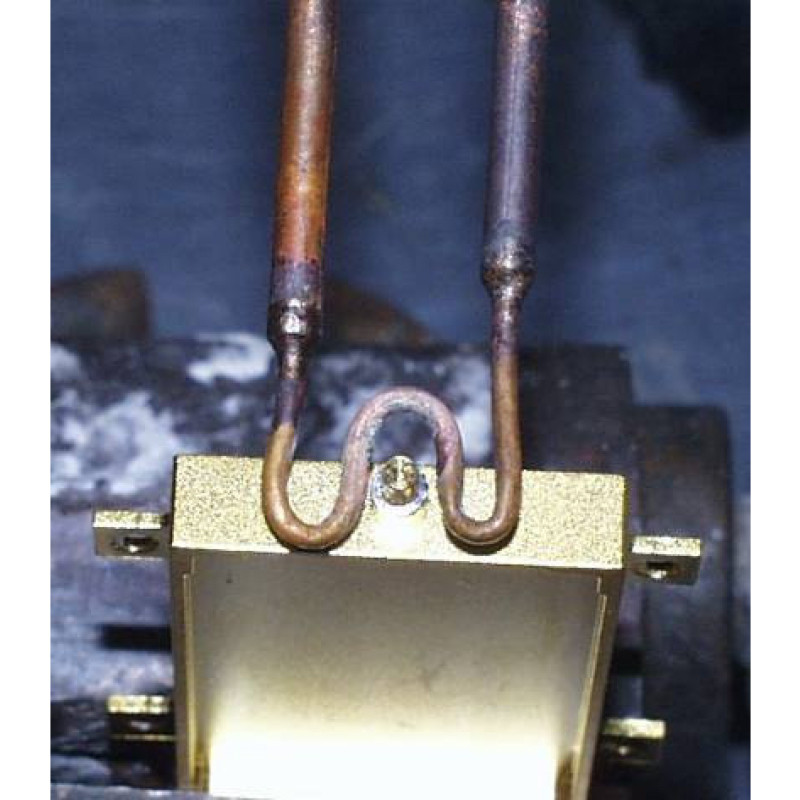

Objective: Soldering a fiber optics cable in a ferrule to form a hermetic seal.

Frequency: 346 kHz

Material: Panda PM fiber 0.0098” (.25mm) dia, kovar ferrule 0.086” (2.2mm) dia and metal enclosure 1.96” x 1.06” x 0.23” thick (50mm x 27mm x 5.9mm thick), solder preforms and flux

Temperature: 450 ºF (232 ºC)

A single turn channel “C” coil is used for this soldering application. Assembly is fluxed at the joint area and power is applied for 15 seconds to create the hermetic seal in the ferrule. The customer chose our solution due to the ability to design the single channel “C” coil. The coil heats quickly so that the heat does not travel to heat sensitive components in the case.

Вашу оцінку відгуку не було надіслано

Поскаржитись на відгук

Скаргу надіслано

Ваш відгук не надіслано

Написати свій відгук

Відгук надіслано

Ваш відгук не надіслано