Ви повинні увійти в систему

Category

Фотографії призначені тільки для інформаційних цілей. Подивитися специфікацію продукту

please use latin characters

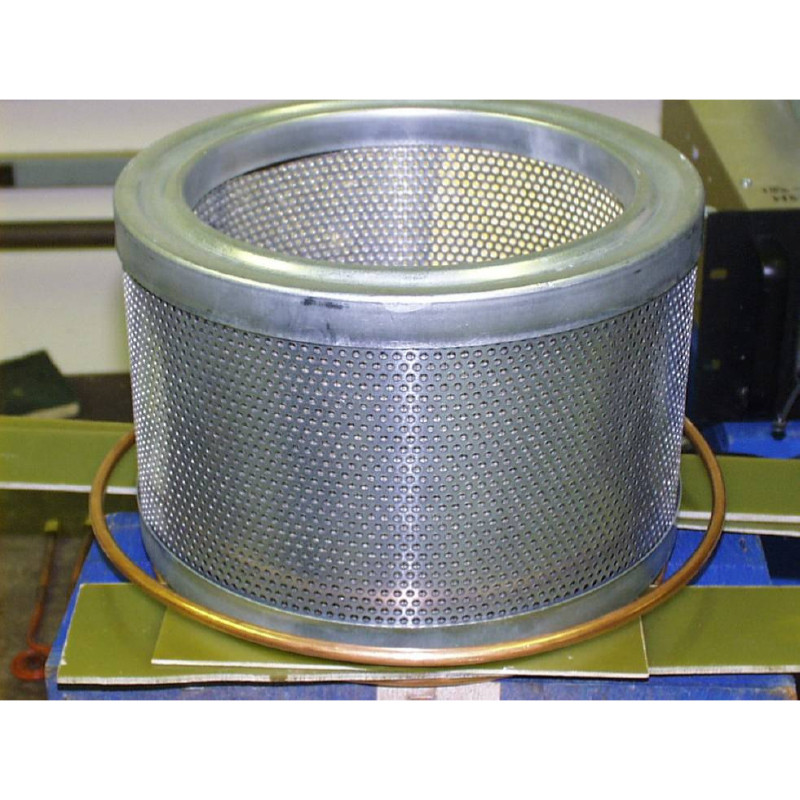

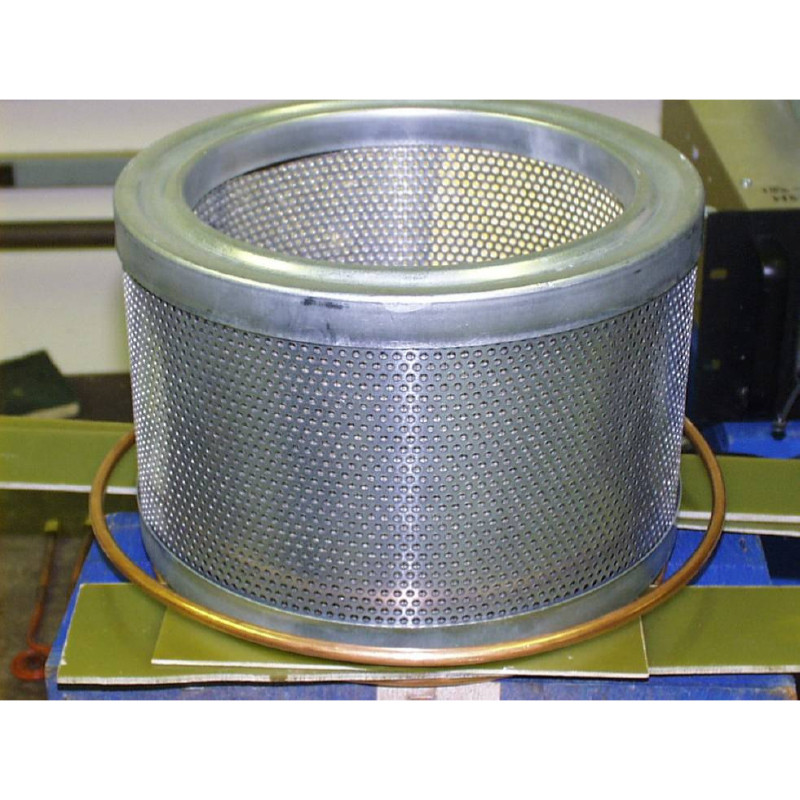

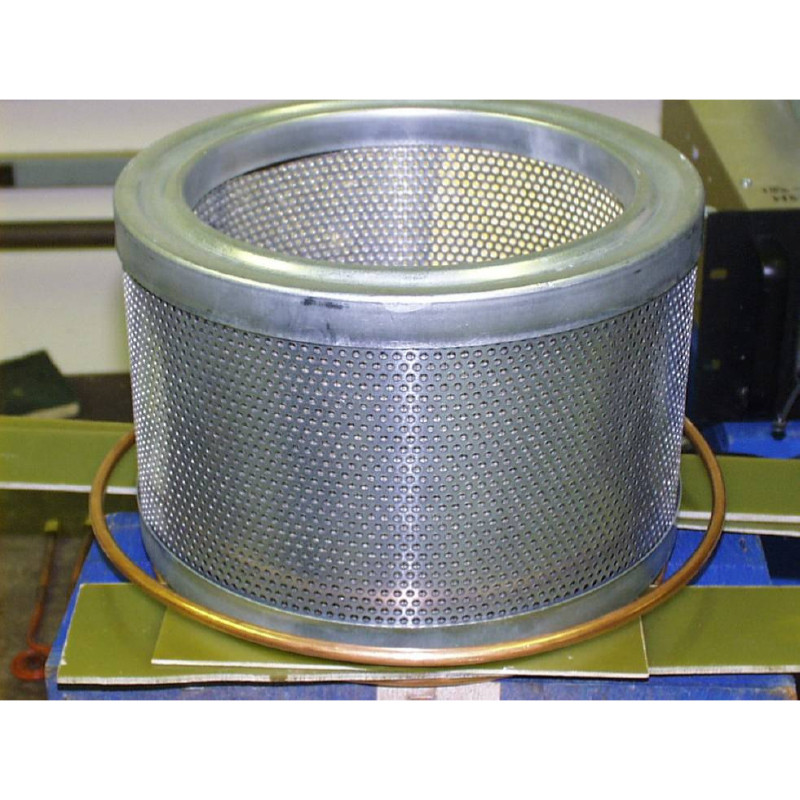

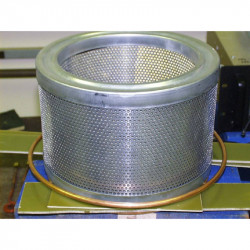

Objective: To cure adhesive in aluminum filter ends.

Frequency: 277 kHz

Material: Aluminum filter, steel end caps & plastisol adhesive

Temperature: 200 °F (94 °C)

A four turn helical coil is used to cure the plastisol adhesive. One filter end cap is filled with adhesive, attached to the filter and heated 90 seconds to cure the adhesive. The filter assembly is then flipped; the second end cap is filled with adhesive and applied to the filter. Heat is applied to that end cap for 90 seconds to cure the adhesive. A second coil is recommended to heat 2 parts at once which would reduce the heat time to 45 seconds per part. The heat time can be further reduced by increasing the number of power supplies and coils.

Ви зацікавлені у цьому продукті? Вам потрібна додаткова інформація або індивідуальні розцінки?

Ви повинні увійти в систему

Objective: To cure adhesive in aluminum filter ends.

Frequency: 277 kHz

Material: Aluminum filter, steel end caps & plastisol adhesive

Temperature: 200 °F (94 °C)

A four turn helical coil is used to cure the plastisol adhesive. One filter end cap is filled with adhesive, attached to the filter and heated 90 seconds to cure the adhesive. The filter assembly is then flipped; the second end cap is filled with adhesive and applied to the filter. Heat is applied to that end cap for 90 seconds to cure the adhesive. A second coil is recommended to heat 2 parts at once which would reduce the heat time to 45 seconds per part. The heat time can be further reduced by increasing the number of power supplies and coils.

Вашу оцінку відгуку не було надіслано

Поскаржитись на відгук

Скаргу надіслано

Ваш відгук не надіслано

Написати свій відгук

Відгук надіслано

Ваш відгук не надіслано