Musisz być zalogowany/a

Category

Zdjęcia mają charakter wyłacznie informacyjny. Zobacz specyfikację produktu

please use latin characters

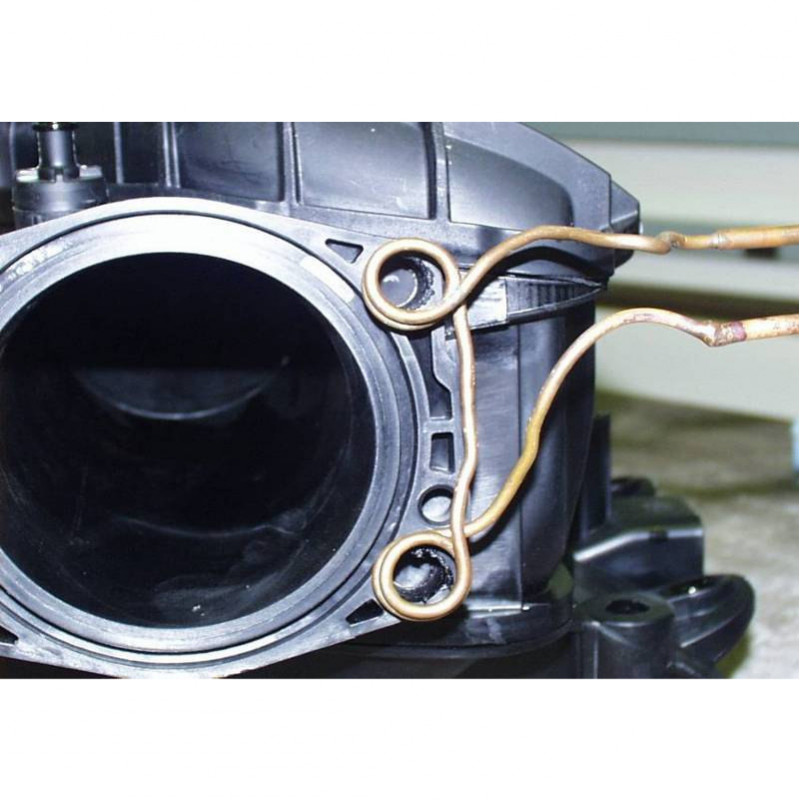

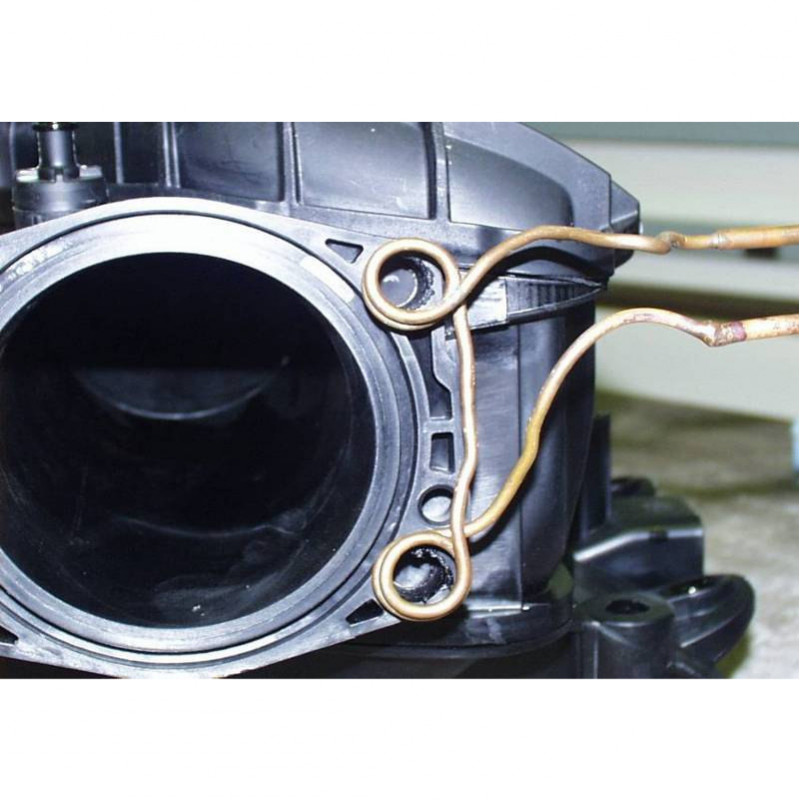

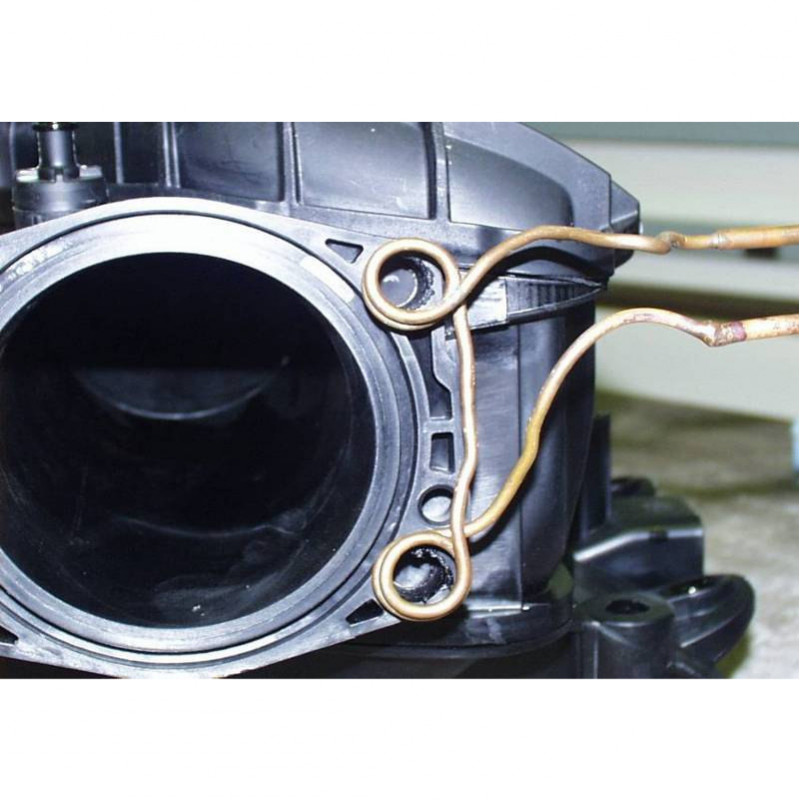

Objective: Heat a 0.50” (12.7)mm brass insert for debonding application.

Frequency: 215 kHz

Material: Intake manifold and 0.50” (12.7)mm diameter brass insert.

Temperature: 500 °F (260 °C)

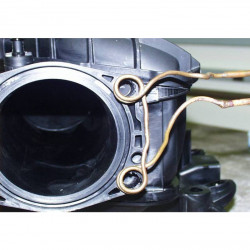

A four-turn two-position helical coil is used to debond the inserts from the plastic. The coil is placed against the manifold and power is applied to the two inserts for 15 seconds to soften the plastic. Power is turned off and a threaded steel screw is inserted into the parts and the inserts are easily removed from the manifold.

This debonding process is for recycling 10,000 defective parts that QES has received the contract for debond the brass from the plastic and recycle the plastic. Induction makes it possible to simultaneously heat both inserts for removal saving time in the recycle process.

Jesteś zainteresowany tym produktem? Potrzebujesz dodatkowych informacji lub indywidualnej wyceny?

Musisz być zalogowany/a

Objective: Heat a 0.50” (12.7)mm brass insert for debonding application.

Frequency: 215 kHz

Material: Intake manifold and 0.50” (12.7)mm diameter brass insert.

Temperature: 500 °F (260 °C)

A four-turn two-position helical coil is used to debond the inserts from the plastic. The coil is placed against the manifold and power is applied to the two inserts for 15 seconds to soften the plastic. Power is turned off and a threaded steel screw is inserted into the parts and the inserts are easily removed from the manifold.

This debonding process is for recycling 10,000 defective parts that QES has received the contract for debond the brass from the plastic and recycle the plastic. Induction makes it possible to simultaneously heat both inserts for removal saving time in the recycle process.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent