Ви повинні увійти в систему

-

WróćX

-

компоненти

-

-

Category

-

Напівпровідники

- Діоди

- Тиристори

-

Електро-ізольовані модулі

- Електроізольовані модулі | ВІШАЙ (ІЧ)

- Електроізольовані модулі | INFINEON (EUPEC)

- Електроізольовані модулі | Семікрон

- Електроізольовані модулі | POWEREX

- Електроізольовані модулі | IXYS

- Електроізольовані модулі | ПОСЕЙКО

- Електроізольовані модулі | ABB

- Електроізольовані модулі | ТЕХСЕМ

- Przejdź do podkategorii

- Випрямні мости

-

Транзистори

- Транзистори | GeneSiC

- Модулі SiC MOSFET | Mitsubishi

- Модулі SiC MOSFET | STARPOWER

- Модулі ABB SiC MOSFET

- Модулі IGBT | MITSUBISHI

- Транзисторні модулі | MITSUBISHI

- Модулі MOSFET | MITSUBISHI

- Транзисторні модулі | ABB

- Модулі IGBT | POWEREX

- Модулі IGBT | INFINEON (EUPEC)

- Напівпровідникові елементи з карбіду кремнію (SiC)

- Przejdź do podkategorii

- Драйвери

- Блоки потужності

- Przejdź do podkategorii

- Електричні перетворювачі

-

Пасивні компоненти (конденсатори, резистори, запобіжники, фільтри)

- Резистори

-

Запобіжники

- Мініатюрні запобіжники для електронних плат серії ABC і AGC

- Швидкі трубчасті запобіжники

- Повільні запобіжники з характеристиками GL / GG і AM

- Ультрашвидкі плавкі запобіжники

- Швидкі запобіжники: британський та американський стандарт

- Швидкі запобіжники. Європейський стандарт

- Тягові запобіжники

- Високовольтні запобіжні

- Przejdź do podkategorii

-

Конденсатори

- Конденсатори для електродвигунів

- Електролітичні конденсатори

- Снабберні конденсатори

- Конденсатори потужності

- Конденсатори для DC ланцюгів

- Конденсатори для компенсації пасивної потужності

- Високовольтні конденсатори

- Конденсатори великої потужності для індукційного нагріву

- Конденсатори для зберігання імпульсів та енергії

- Конденсатори DC LINK

- Конденсатори для ланцюгів змінного / постійного струму

- Przejdź do podkategorii

- EMI фільтри

- Іоністори (супер-конденсатори)

- Захист від стрибків напруги

- Фільтри виявлення випромінювання TEMPEST

- Розрядник

- Przejdź do podkategorii

-

Реле та контактори

- Реле та контактори - теорія

- Напівпровідникові реле AC 3-фазні

- Напівпровідникові реле DC

- Контролери, системи управління та аксесуари

- Системи плавного пуску і реверсивні контактори

- Електромеханічні реле

- Контактори

- Оборотні перемикачі

-

Напівпровідникові реле AC 1-фазні

- РЕЛЕ AC 1-ФАЗНЫЕ СЕРИИ 1 D2425 | D2450

- Однофазное реле AC серии CWA и CWD

- Однофазное реле AC серии CMRA и CMRD

- Однофазное реле AC серии PS

- Реле AC двойное и четверное серии D24 D, TD24 Q, H12D48 D

- Однофазні твердотільні реле серії gn

- Однофазні напівпровідникові реле змінного струму, серія ckr

- Однофазні реле змінного струму ERDA та ERAA для DIN-рейки

- Однофазні реле змінного струму для струму 150А

- Подвійні твердотільні реле, інтегровані з радіатором для DIN-рейки

- Przejdź do podkategorii

- Напівпровідникові реле AC 1-фазні для друкованих плат

- Інтерфейсні реле

- Przejdź do podkategorii

- Індукційні компоненти

- Радіатори, варистори, термічний захист

- Вентилятори

- Кондиціонери, обладнання для шаф електричних, охолоджувачі

-

Батареї, зарядні пристрої, буферні блоки живлення та інвертори

- Батареї, зарядні пристрої - теоретичний опис

- Літій-іонні батареї. Спеціальні батареї. Система управління акумулятором (BMS)

- Батареї

- Зарядні пристрої та аксесуари

- Резервне джерело живлення ДБЖ та буферні джерела живлення

- Перетворювачі та аксесуари для фотоелектрики

- Зберігання енергії

- Паливні елементи

- Літій-іонні акумулятори

- Przejdź do podkategorii

-

Автоматика

- Підйомники Spiralift

- Запчастини для дронів Futaba

- Кінцеві вимикачі, Мікровимикачі

- Датчики Перетворювачі

- Пірометри

- Лічильники, Реле часу, Панельні вимірювальні прилади

- Промислові захисні пристрої

- Світлові і звукові сигнальні установки

- Термокамери, Тепловізори

- LED-екрани

- Керуюча апаратура

- Przejdź do podkategorii

-

Провід, літцендрат, гофровані рукави, гнучкі з'єднання

- Дроти

- Кабельні вводи та муфти

- Багатожильні дроти Lica

-

Кабелі і дроти для спеціальних застосувань

- Подовжувальні та компенсаційні дроти

- Дроти для термопар

- Приєднувальні дроти для датчиків PT

- Багатожильні дроти темп. -60C до +1400C

- Дроти середньої напруги

- Дроти запалювання

- Нагрівальні дроти

- Одножильні дроти темп. -60C до +450C

- Залізничні дроти

- Нагрівальні дроти для вибухонебезпечних зон

- Przejdź do podkategorii

- Оболонки

-

Плетені кабелі

- Плоскі плетені кабелі

- Круглі плетені кабелі

- Дуже гнучкі плетені кабелі - плоскі

- Дуже гнучкі плетені кабелі - круглі

- Мідні циліндричні плетені кабелі

- Мідні циліндричні плетені кабелі і кожуха

- Гнучкі заземлювальні стрічки

- Циліндричні плетені дроти з лудженої і нержавіючої сталі

- Мідні ізольовані плетені дроти PCV - температура до 85 градусів C

- Плоскі алюмінієві плетені дроти

- З'єднувальний набір - плетені дроти і трубки

- Przejdź do podkategorii

- Аксесуари для тяги

- Кабельні наконечники

- Ізольовані еластичні шини

- Багатошарові гнучкі шини

- Системи прокладки кабелю (PESZLE)

- Przejdź do podkategorii

- Zobacz wszystkie kategorie

-

Напівпровідники

-

-

- Постачальники

-

додатки

- Energy bank

- ІНДУКЦІЙНИЙ НАГРІВ

- Автоматизація HVAC

- Верстати з ЧПУ

- ВИМІРЮВАННЯ ТА РЕГУЛЮВАННЯ ТЕМПЕРАТУРИ

- Вимірювання та регулювання температури

- ГІРНИЧОДОБУВНА ПРОМИСЛОВІСТЬ, СТАЛЕЛИВАРНІ КОМБІНАТИ, ГЗК

- ДВИГУНИ І ТРАНСФОРМАТОРИ

- ЕНЕРГЕТИКА

- ЗВАРЮВАЛЬНІ АПАРАТИ

- КОМПЛЕКТУЮЧІ ДЛЯ РОЗПОДІЛЬНИХ, ТЕЛЕКОМУНІКАЦІЙНИХ ШАФ І ШАФ УПРАВЛІННЯ

- МАШИНИ ДЛЯ ДЕРЕВООБРОБКИ ТА СУШІННЯ ДЕРЕВИНИ

- ПОЛІГРАФІЯ

- ПРИВІД ПОСТІЙНОГО І ЗМІННОГО СТРУМУ

- ПРИЛАДИ ТА ОБЛАДНАННЯ ДЛЯ ВИБУХОНЕБЕЗПЕЧНИХ ЗОН (EX)

- ПРИСТРОЇ БЕЗПЕРЕБІЙНОГО ЖИВЛЕННЯ (UPS) І ВИПРЯМЛЯЧІ

- ПРОМИСЛОВІ ЗАСОБИ ЗАХИСТУ

- ПРОМИСЛОВА АВТОМАТИКА

- ТЕРМОФОРМОВОЧНІ МАШИНИ

- ТЯГОВИЙ ПРИВІД

-

монтаж

-

-

Індуктори

-

-

Індукційні прилади

-

-

Сервіс

-

- Контакт

- Zobacz wszystkie kategorie

1700V X-Series HVIGBT Power Modules with Excellent Performance and Reliability

1700V X-Series HVIGBT Power Modules with Excellent Performance and Reliability

High performance 1700V HVIGBT power modules providing reliable solutions for railway applications.

The railway applications require components with high quality and high efficiency, especially the converter drives should have reliable and robust switching devices. It is an established practice to utilize 1700V IGBT modules to operate directly on the catenary with the DC voltages below 1000V or in 3-level configuration with catenary DC voltages above 1000V

By Eugen Wiesner, Dr. Nils Soltau MITSUBISHI ELECTRIC EUROPE B. V. Nobuhiko Tanaka MITSUBISHI ELECTRIC CORPORATION

Mitsubishi Electric continuously improves the quality of the IGBT power modules concerning three key concepts:

- Robust power module design considering high margin of safe operating area

- Low power losses using latest chip generation

- Quality control with dedicated production lines and traceability

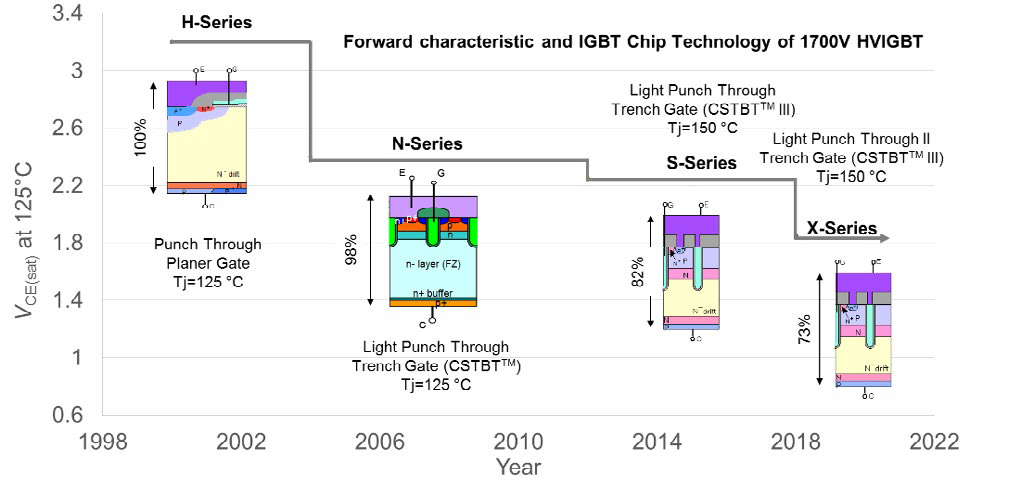

Mitsubishi Electric has several years of experience and a long development history of 1700V modules for railway application from the start of this century. This year MITSUBISHI ELECTRIC has released the latest generation of 1700V IGBT power modules called X-Series that satisfies requirements of railway applications. Fig. 1 shows the historical evolution of the 1700V HVIGBT modules indicating the continuous reduction of the IGBT forward voltage. The IGBT forward voltage contributes to the converter power loss reduction. IGBT forward voltage reduction has continuously been achieved during the development o each series. The remarkable step in the reduction of the forward voltage was the implementation of the trench gate structure in the beginning of 2000s [1].

Figure 1: Chronology of 1700V IGBT chip forward voltage reduction.

For further reducing the forward voltage the IGBT chip structure was optimized and thinner chips were used. In the latest 1700V X-Series the state of the art 7th Generation chip technology is applied in conjunction with a further reduction of IGBT thickness. Additionally, several optimizations on the chip back side (collector side) were carried out.

| Circuit | Foot print | Current rating | Type name |

|---|---|---|---|

| Single 1 in 1 |

190mm x 140mm |

2400A 3600A |

CM2400HCB-34X CM3600HC-34X |

| Single 1 in 1 |

130mm x 140mm |

1600A 2400A |

CM1600HC-34X CM2400HC-34X |

| Chopper | 130mm x 140mm |

1200A | CM1200E4C-34X |

| Dual 2 in 1 |

100mm x 140mm |

1000A 1200A 1200A |

CM1000DC-34X (Si) CM1200DC-34X (Si) CMH1200DC-34X (SiC hybrid) |

Table 1: 1700V X-Series Line-up

The 1700V X-Series contains three module packages. The first is the conventional package with the footprint dimensions of 190mm x 140mm. The second type is also conventional having the footprint size of 130mm x 140mm. The third package is the new standard dual package called LV100 with the footprint of 140mm x 100mm. The complete line-up of the X-Series 1700V IGBT modules is shown in table 1.

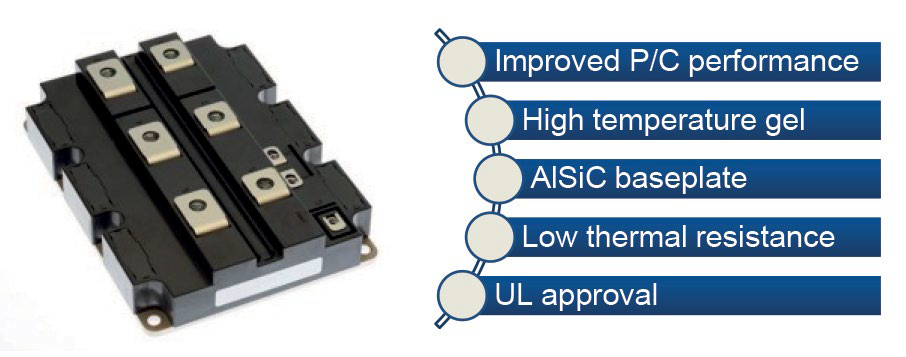

High current 1700V HVIGBT X-Series single modules.

The conventional 1in1 packages were completely reworked compared to the previous N-Series. The chip layout inside the module was optimized for better thermal conductivity and better power cycling life time. Inside the module a newly developed high performance silicone gel is used. The operation temperature now is covering the range from -50°C to 150°C. The new X-series modules will receive the UL certification. Furthermore, these modules were proven during the qualification against the humidity influence. That is an important factor for the operation in the harsh railway environment.

Figure 2: 1700V X-Series single modules features

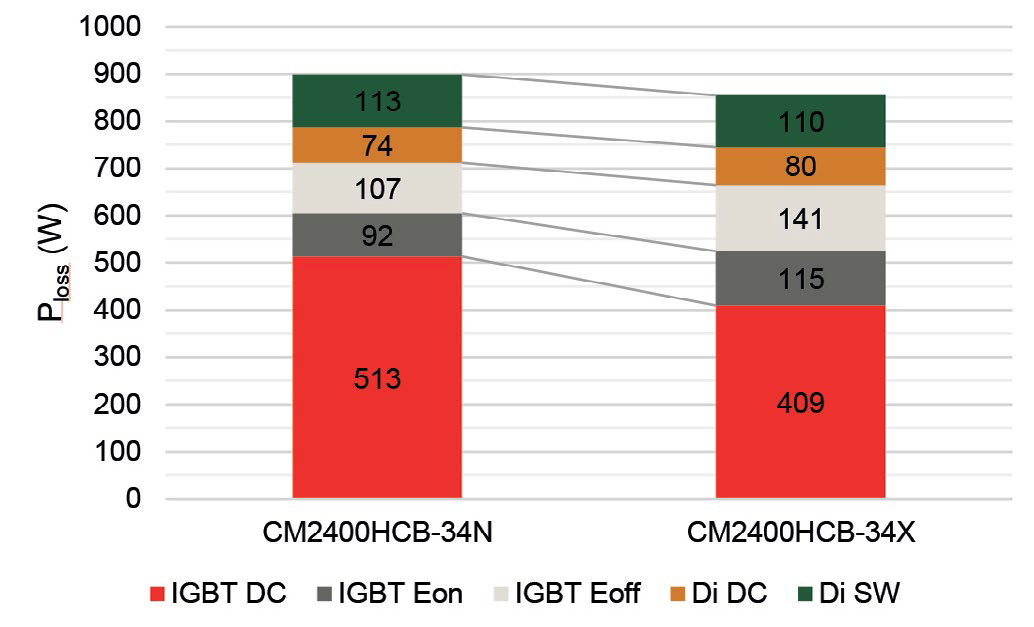

Figure 3: X-Series power loss simulation under the conditions: VCC=850V, Ipeak=1200A, PF=0.85, M=1, fsw=1kHz, fo=60Hz, Tj=125°C.

The standard package type is available since many years on the market. Then converter manufacturers have proven reliability records of the converters having this package type in the field. Now it is possible to boost the converter performance using the cutting edge technology of X-Series modules. The small size package (130mm x140mm) is favorite choice for compact water cooled application. The large package (190mm x 140mm) with its low case to heatsink thermal resistance Rth(c-f) is especially attractive for air cooled applications. In the Figure 3 is shown the potential of the power loss reduction for single X-Series device CM2400HCB-34X compared to the previous N-Series.

Dual LV100 X-Series 1700V modules

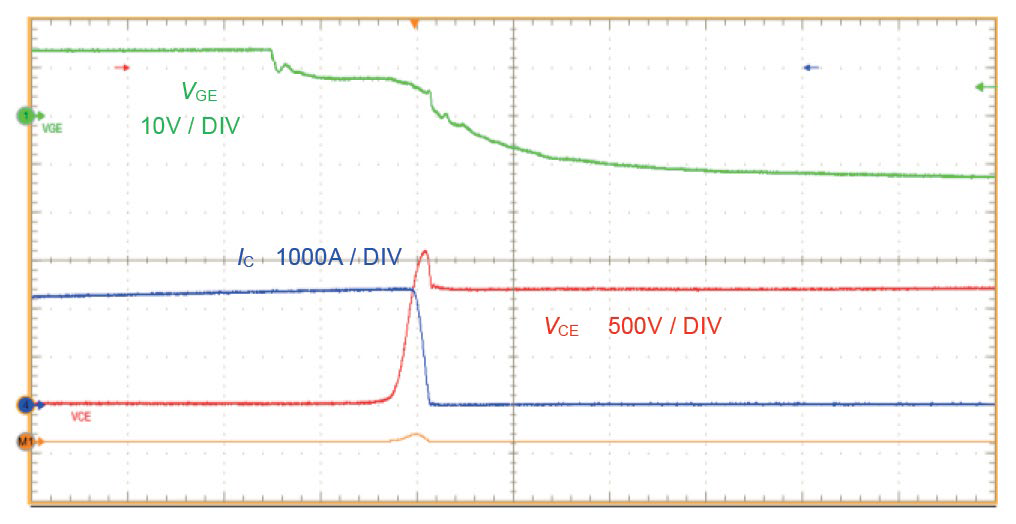

The standard LV100 package was developed with the target to cope with high switching speed devices like 1700V X-series modules and modules having Silicon Carbide technology. The low inductive package structure is one of the key advantages of this device.

Thanks to low package inductance and comfortable construction of the DC-Link connection, it is possible to switch off the device at high current without increasing the turn off gate resistance. The IGBT turn off measurement result at maximum turn off conditions VCC=1200V, IC=2400A, Rg(off)=Rg(nominal), Ls=40nH and TJ=150°C is shown in Figure 4. Even at such conditions the overvoltage spike is below the maximum blocking voltage of 1700V.

Figure 4: CM1200DC-34X turn off event at high current and maximum DC-Link voltage

Furthermore the diode performance was enhanced in the LV100 module. Compared to the previous S-Series the diode forward voltage was reduced by more than 15%. At the same time the reverse recovery energy was reduced by more than 25%.

The current density in the LV100 package was increased by about 30% from 13.2A/cm2 to 17.1A/cm2 for CM1200DC-34X compared to CM2400HC-34N device. To carry the high output current the device has three screws at AC output terminal.

The forward characteristics of IGBT and FWDi has positive temperature coefficients that is essential for good module parallel operation.

Additionally this package provide the flexibility of converter power scaling by module paralleling. This point is also an additional challenge for converter designer. To overcome this challenge the propose reference test setup [2] can be used in combination with these modules.

Conclusion

The introduced 1700V X-Series utilize the cutting edge chip and package technologies. The modules offers the highest reliability combined with low power losses and flexibility.

References

[1] S. Iura, E. Suekawa, K. Morishita, M. Koga, E. Thal. “New 1700V IGBT Modules with CSTBT.” PCIM Europe 2004.

[2] Dr. J. Weigel. “Paralleling of High Power Dual Modules: Standard Building Block Design for Evaluation of Module Related Current Mismatch.” EPE’18 ECCE Europe

Related posts

Now available – DC/DC converters from PREMIUM

Now available – DC/DC converters from PREMIUM

New release in DACPOL lighting for lathes – Kira covers

New release in DACPOL lighting for lathes – Kira covers

Leave a comment