Ви повинні увійти в систему

-

WróćX

-

компоненти

-

-

Category

-

Напівпровідники

- Діоди

- Тиристори

-

Електро-ізольовані модулі

- Електроізольовані модулі | ВІШАЙ (ІЧ)

- Електроізольовані модулі | INFINEON (EUPEC)

- Електроізольовані модулі | Семікрон

- Електроізольовані модулі | POWEREX

- Електроізольовані модулі | IXYS

- Електроізольовані модулі | ПОСЕЙКО

- Електроізольовані модулі | ABB

- Електроізольовані модулі | ТЕХСЕМ

- Przejdź do podkategorii

- Випрямні мости

-

Транзистори

- Транзистори | GeneSiC

- Модулі SiC MOSFET | Mitsubishi

- Модулі SiC MOSFET | STARPOWER

- Модулі ABB SiC MOSFET

- Модулі IGBT | MITSUBISHI

- Транзисторні модулі | MITSUBISHI

- Модулі MOSFET | MITSUBISHI

- Транзисторні модулі | ABB

- Модулі IGBT | POWEREX

- Модулі IGBT | INFINEON (EUPEC)

- Напівпровідникові елементи з карбіду кремнію (SiC)

- Przejdź do podkategorii

- Драйвери

- Блоки потужності

- Przejdź do podkategorii

- Електричні перетворювачі

-

Пасивні компоненти (конденсатори, резистори, запобіжники, фільтри)

- Резистори

-

Запобіжники

- Мініатюрні запобіжники для електронних плат серії ABC і AGC

- Швидкі трубчасті запобіжники

- Повільні запобіжники з характеристиками GL / GG і AM

- Ультрашвидкі плавкі запобіжники

- Швидкі запобіжники: британський та американський стандарт

- Швидкі запобіжники. Європейський стандарт

- Тягові запобіжники

- Високовольтні запобіжні

- Przejdź do podkategorii

-

Конденсатори

- Конденсатори для електродвигунів

- Електролітичні конденсатори

- Снабберні конденсатори

- Конденсатори потужності

- Конденсатори для DC ланцюгів

- Конденсатори для компенсації пасивної потужності

- Високовольтні конденсатори

- Конденсатори великої потужності для індукційного нагріву

- Конденсатори для зберігання імпульсів та енергії

- Конденсатори DC LINK

- Конденсатори для ланцюгів змінного / постійного струму

- Przejdź do podkategorii

- EMI фільтри

- Іоністори (супер-конденсатори)

-

Захист від стрибків напруги

- Захист від перенапруги для коаксіального застосування

- Захист від перенапруг для систем відеоспостереження

- Захист від перенапруги для силових кабелів

- Розрядники перенапруги для світлодіодів

- Розрядники перенапруги для фотоелектрики

- Захист системи зважування

- Захист від перенапруги для Fieldbus

- Przejdź do podkategorii

- Przejdź do podkategorii

-

Реле та контактори

- Реле та контактори - теорія

- Напівпровідникові реле AC 3-фазні

- Напівпровідникові реле DC

- Контролери, системи управління та аксесуари

- Системи плавного пуску і реверсивні контактори

- Електромеханічні реле

- Контактори

- Оборотні перемикачі

-

Напівпровідникові реле AC 1-фазні

- РЕЛЕ AC 1-ФАЗНЫЕ СЕРИИ 1 D2425 | D2450

- Однофазное реле AC серии CWA и CWD

- Однофазное реле AC серии CMRA и CMRD

- Однофазное реле AC серии PS

- Реле AC двойное и четверное серии D24 D, TD24 Q, H12D48 D

- Однофазні твердотільні реле серії gn

- Однофазні напівпровідникові реле змінного струму, серія ckr

- Однофазні реле змінного струму ERDA та ERAA для DIN-рейки

- Однофазні реле змінного струму для струму 150А

- Подвійні твердотільні реле, інтегровані з радіатором для DIN-рейки

- Przejdź do podkategorii

- Напівпровідникові реле AC 1-фазні для друкованих плат

- Інтерфейсні реле

- Przejdź do podkategorii

- Індукційні компоненти

- Радіатори, варистори, термічний захист

- Вентилятори

- Кондиціонери, обладнання для шаф електричних, охолоджувачі

-

Батареї, зарядні пристрої, буферні блоки живлення та інвертори

- Батареї, зарядні пристрої - теоретичний опис

- Літій-іонні батареї. Спеціальні батареї. Система управління акумулятором (BMS)

- Батареї

- Зарядні пристрої та аксесуари

- Резервне джерело живлення ДБЖ та буферні джерела живлення

- Перетворювачі та аксесуари для фотоелектрики

- Зберігання енергії

- Паливні елементи

- Літій-іонні акумулятори

- Przejdź do podkategorii

-

Автоматика

- Futaba Drone Parts

- Кінцеві вимикачі, Мікровимикачі

- Датчики Перетворювачі

- Пірометри

- Лічильники, Реле часу, Панельні вимірювальні прилади

- Промислові захисні пристрої

- Світлові і звукові сигнальні установки

- Термокамери, Тепловізори

- LED-екрани

- Керуюча апаратура

-

Реєстратори

- Реєстратори температури з записом на стрічку і з цифровим індикатором - AL3000

- Мікропроцесорні реєстратори з екраном LCD серія KR2000

- Реєстратор KR5000

- Вимірювач з функцією реєстрації вологості і температури HN-CH

- Експлуатаційні матеріали для реєстраторів

- Компактний графічний реєстратор 71VR1

- Реєстратор KR 3000

- Реєстратор PC серії R1M

- Реєстратор PC серії R2M

- Реєстратор PC, USB, 12 ізольованих входів – RZMS

- Реєстратор PC, USB, 12 ізольованих входів – RZUS

- Przejdź do podkategorii

- Przejdź do podkategorii

-

Провід, літцендрат, гофровані рукави, гнучкі з'єднання

- Дроти

- Багатожильні дроти Lica

-

Кабелі і дроти для спеціальних застосувань

- Подовжувальні та компенсаційні дроти

- Дроти для термопар

- Приєднувальні дроти для датчиків PT

- Багатожильні дроти темп. -60C до +1400C

- Дроти середньої напруги

- Дроти запалювання

- Нагрівальні дроти

- Одножильні дроти темп. -60C до +450C

- Залізничні дроти

- Нагрівальні дроти для вибухонебезпечних зон

- Przejdź do podkategorii

- Оболонки

-

Плетені кабелі

- Плоскі плетені кабелі

- Круглі плетені кабелі

- Дуже гнучкі плетені кабелі - плоскі

- Дуже гнучкі плетені кабелі - круглі

- Мідні циліндричні плетені кабелі

- Мідні циліндричні плетені кабелі і кожуха

- Гнучкі заземлювальні стрічки

- Циліндричні плетені дроти з лудженої і нержавіючої сталі

- Мідні ізольовані плетені дроти PCV - температура до 85 градусів C

- Плоскі алюмінієві плетені дроти

- З'єднувальний набір - плетені дроти і трубки

- Przejdź do podkategorii

- Аксесуари для тяги

- Кабельні наконечники

- Ізольовані еластичні шини

- Багатошарові гнучкі шини

- Системи прокладки кабелю (PESZLE)

- Шланги

- Przejdź do podkategorii

- Zobacz wszystkie kategorie

-

Напівпровідники

-

-

- Постачальники

-

додатки

- Energy bank

- ІНДУКЦІЙНИЙ НАГРІВ

- Автоматизація HVAC

- Верстати з ЧПУ

- ВИМІРЮВАННЯ ТА РЕГУЛЮВАННЯ ТЕМПЕРАТУРИ

- Вимірювання та регулювання температури

- ГІРНИЧОДОБУВНА ПРОМИСЛОВІСТЬ, СТАЛЕЛИВАРНІ КОМБІНАТИ, ГЗК

- ДВИГУНИ І ТРАНСФОРМАТОРИ

- ЕНЕРГЕТИКА

- ЗВАРЮВАЛЬНІ АПАРАТИ

- КОМПЛЕКТУЮЧІ ДЛЯ РОЗПОДІЛЬНИХ, ТЕЛЕКОМУНІКАЦІЙНИХ ШАФ І ШАФ УПРАВЛІННЯ

- МАШИНИ ДЛЯ ДЕРЕВООБРОБКИ ТА СУШІННЯ ДЕРЕВИНИ

- ПОЛІГРАФІЯ

- ПРИВІД ПОСТІЙНОГО І ЗМІННОГО СТРУМУ

- ПРИЛАДИ ТА ОБЛАДНАННЯ ДЛЯ ВИБУХОНЕБЕЗПЕЧНИХ ЗОН (EX)

- ПРИСТРОЇ БЕЗПЕРЕБІЙНОГО ЖИВЛЕННЯ (UPS) І ВИПРЯМЛЯЧІ

- ПРОМИСЛОВІ ЗАСОБИ ЗАХИСТУ

- ПРОМИСЛОВА АВТОМАТИКА

- ТЕРМОФОРМОВОЧНІ МАШИНИ

- ТЯГОВИЙ ПРИВІД

-

монтаж

-

-

Індуктори

-

-

Індукційні прилади

-

-

https://www.dacpol.eu/pl/naprawy-i-modernizacje

-

-

Сервіс

-

- Контакт

- Zobacz wszystkie kategorie

High Power Density, High Performance X-Series 4500V IGBT Power Modules

High Power Density, High Performance X-Series 4500V IGBT Power Modules

Mitsubishi Electric has developed high performance 4500V IGBT power modules providing reliable solutions for medium voltage drive, railway and power transmission applications.

By Eugen Wiesner, Dr. Nils Soltau, Eugen Stumpf, Mitsubishi Electric Europe B. V. and Kenji Hatori, Hitoshi Uemura, Mitsubishi Electric Corporation

Introduction

Originally, Mitsubishi Electric started the development of the 4500V IGBTs in the middle of 90s. The first commercialization of standard IGBT modules in this voltage class was started in beginning of 2000s. It was a more efficient and compact solution compared to existing 4500V GTO press pack devices. Mainly this development was driven by railway and medium-voltage (MV) drive applications. Meanwhile, a wide variation of the 4500V IGBT modules is available, such as: dual diode modules, modules with copper and AlSiC base plate, modules with standard (VISO=6 kV) and high isolation packages (VISO=10.2 kV).

Targets of 4500V X-Series IGBT Modules

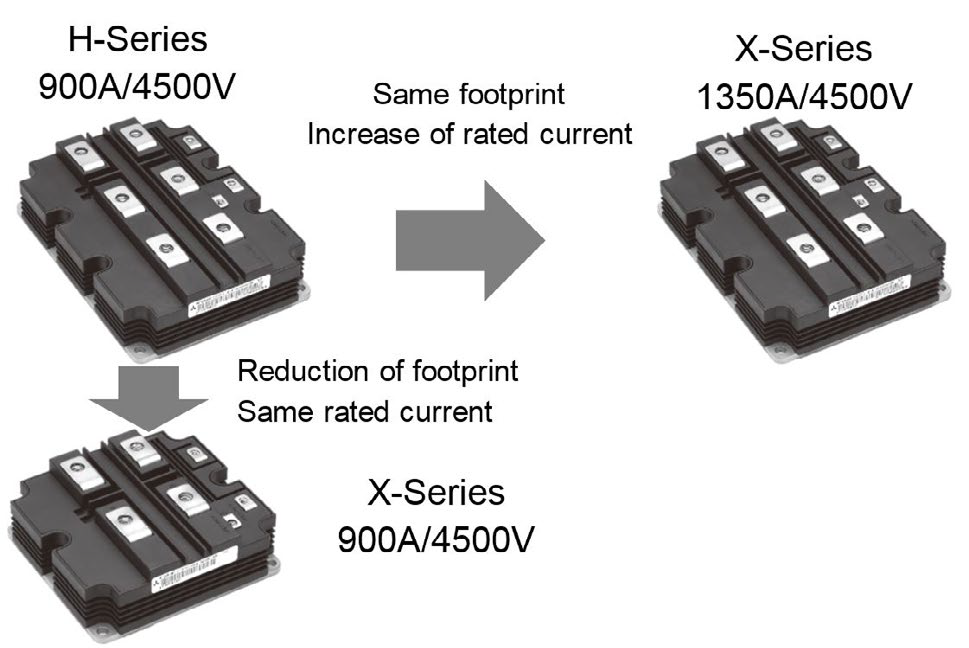

The newly developed 4500V X-Series is already the third series after H-Series and R-Series of MITSUBISHI ELECTRIC IGBT power modules. The line-up of the new X-Series is expanding the existing line-up towards higher power densities (refer Figure 1). The current rating of the large package (footprint: 190mm x 140mm) increases from 900A to 1350A. On the other hand, the 900A rated current also will be made available in smaller package size of 140mm x 130mm.

Figure 1: 4500V X-Series line-up expansion

The standard package type is still very important for different applications due to availability of second source from many IGBT device manufacturers and its proven reliability record in the field for many years. Furthermore, the upgrade or increase of the inverter output power is easily achievable by using the widely commercially available components in the market like heatsinks, gate drivers and bus bars.

The targets for 4500V X-Series device development have been defined based on feedback from customers. These were the following:

- Increasing current rating and module power density

- Reduction of module power losses

- Suitable for various applications having different switching frequency ranges

Six modules have been developed [1] to fulfill the above mentioned market requirements. The overview of the developed 4500V X-Series modules is shown in table 1.

| Isolation voltage | Foot print | Type name |

|---|---|---|

| VISO 10.2 kV | 190mm x 140mm | CM1350HG-90X (VCCmax=3400V) CM1500HG-90X (VCCmax=3200V) |

| 130mm x 140mm | CM900HG-90X (VCCmax=3400V) CM1000HG-90X (VCCmax=3200V) |

|

| VISO 6 kV | 190mm x 140mm | CM1350HC-90X (VCCmax=3400V) CM1500HC-90XA (VCCmax=3000V) |

Table 1: 4500V X-Series Line-up

Improving the Module Power Density

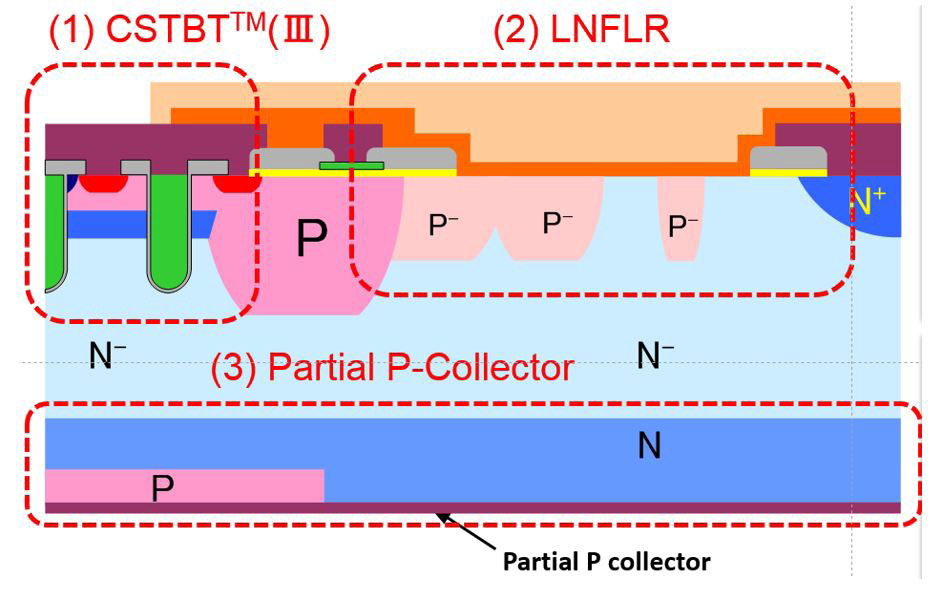

The most challenging requirement was increasing the module power density. The development target was achieved mainly by using the new 7th Gen. Chipset. The 7th Gen. IGBT chip, shown in Figure 2, contributes several significant cutting-edge features. The Carrier Stored Trench-gate Bipolar Transistor structure (CSTBT™) allows reduction of the IGBT forward voltage. The new LNFLR (Linearly- Narrowed Field Limiting Ring) chip termination structure allows for an increase in the active chip area and thereby a reduction of the thermal resistance. Finally, the partial P-Collector technology allows a special capability to manage a wide RBSOA.

Furthermore, the overall packaging technology of 4500V X-Series is improved for managing the increased power density. The optimized internal chip layout reduces the module thermal resistance and increases the power cycling capability. As a result, the junction-tocase thermal resistance was reduced by more than 20% compared to previous R-Series (CM1350HG-90X and CM1200HG-90R). The module performance has been proven and specified for a wide operation temperature range from -50°C to 150°C. The previous 4500V module generations were specified up to 125°C.

Figure 2: 4500V 7th Gen. Chip structure

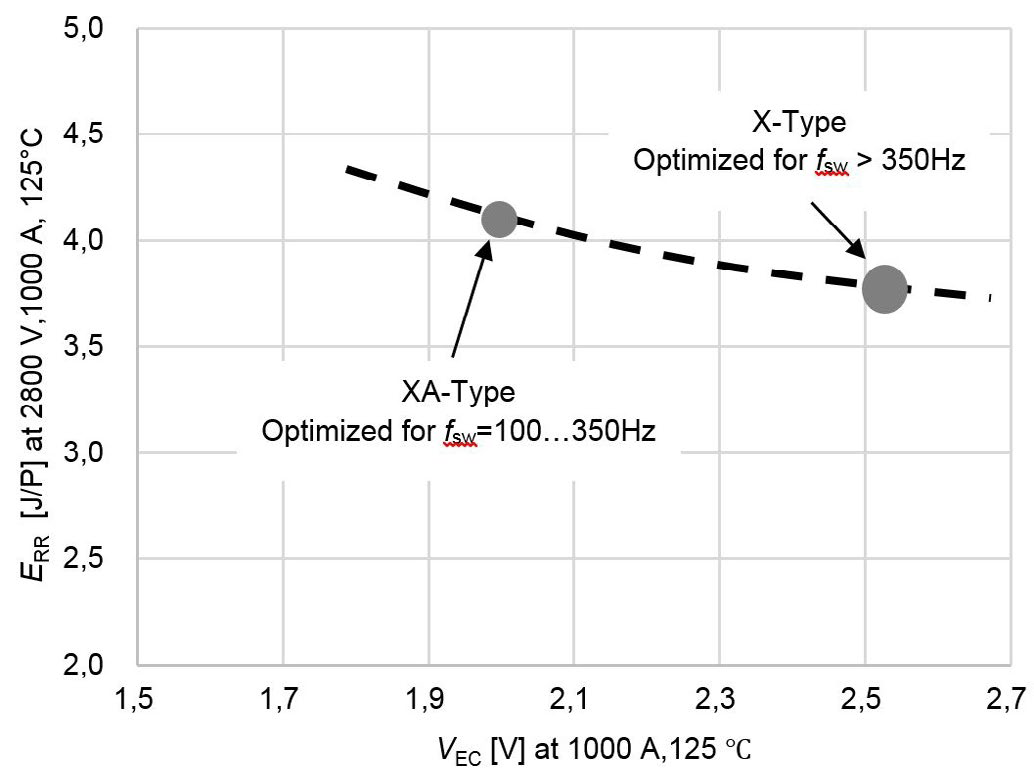

Two different 7th Gen chip set are available, optimized for high and low switching frequency applications respectively. The X-Type chip set is designed for high switching frequency application (> 350Hz). The XA-type chip set achieves the lowest possible forward voltage for the IGBT and the diode. The intended switching frequency ranges from 100Hz to 350Hz. The trade-off between the forward voltage and reverse recovery switching energy for X- and XA- diode is shown in Figure 3.

Figure 3: Diode trade-off between X- and XA device type

Safe Operating Area (SOA) for Each Application

The DC-link voltage is one of the most important stress factors influencing the SOA of IGBT module. Some applications do not require high DC-link voltage. For such cases, the SOA and with it the permitted maximum current rating increase.

The 4500V X-Series device is designed to operate at a maximum DC-link voltage of 3400V. In this case, the module’s rated current is 1350A (CM1350HG-90X). If the required maximum DC-link voltage is reduced to 3200V, the rated current increase up to 1500A (CM1500HG-90X). Both modules have the same electrical characteristics but have different SOA specifications. Each device undergoes shipping tests according to the defined maximum DC-link voltage respectively.

Example of a 3-level NPC Inverter Application

One of the targeted applications for the 4500V modules is the medium voltage (MV) drive application. For these drives, the output voltage range is between 2.3kV and 13.2kV [2]. The most common voltage levels are: 3.3 kV, 4.16kV, 6kV and 6.6kV. For these output voltages, 3-level topology is widely used. For example, these voltages can be covered by devices such as the CM1500(1350)HG-90X (as shown in Table 2). For output voltage levels higher or equal than 4160V - series connection of 4500V modules becomes necessary.

| Inverter output voltage VOUT [Vrms] | Total required inverter DCLink voltage VDC_link [V] | IGBT blocking voltage VCES IGBT [V] | IGBT Series connection | IGBT DC-Link voltage VCC_IGBT [V] |

|---|---|---|---|---|

| 3300 | 4800 | 4500 (CM1500HG-90X) | No | 2400 |

| 4160 | 6200 | 4500 (CM1500HG-90X) | Yes | 1600 |

| 6000 | 8800 | 4500 (CM1500HG-90X) | Yes | 2200 |

| 6600 | 9600 | 4500 (CM1500HG-90X) | Yes | 2400 |

Table 2: Example for 4500V IGBT module based 3-level NPC configurations

Scalability towards lower power ranges can be realized with the CM900HG-90X device or the H- and R-Series modules. The following example shows the potential of the new X-Series compared to the first H-Series in terms of power loss reduction. For the VOUT=3300V output voltage, the necessary DC-Link voltage is about 4800V. In 3-level NPC-configurations, the IGBT module would experience the half the total DC-Link (2400V). In case the heatsink potential would be connected to the middle of the DC-Link the IGBT Module isolation voltage of 10.2 kV(rms) would be sufficient to cover in Table 2 mentioned inverter output voltages.

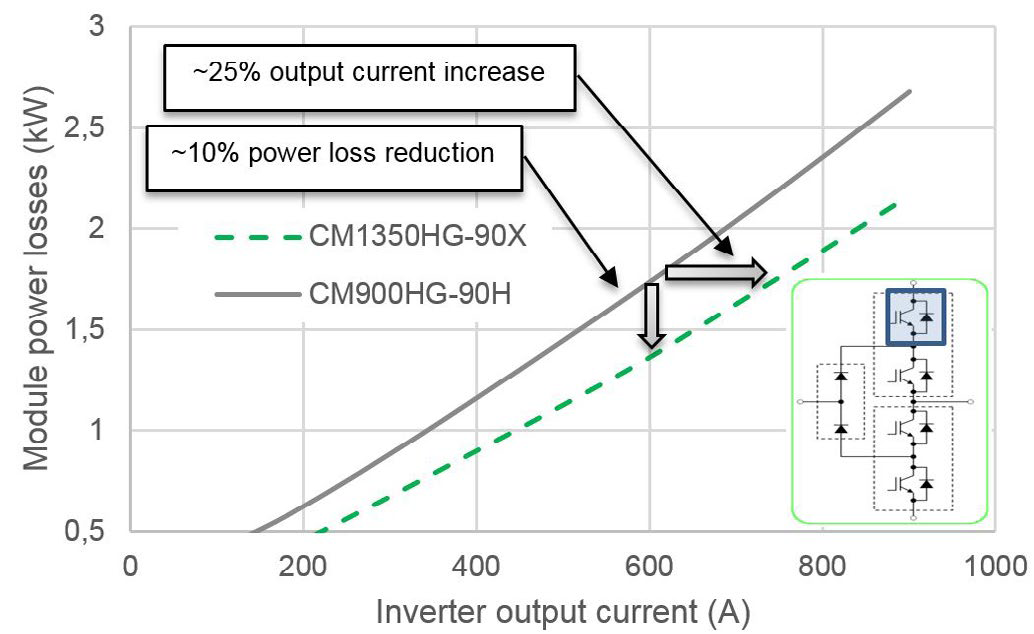

Figure 4: Comparison of the power loss simulation result using the H- and X-Series 190mm x 140mm modules.

Figure 4 shows the power loss simulation versus output current for CM900HG-90H H-Series device and CM1350HG-90X X-Series device. The simulation conditions are:

- Switching frequency fsw=0.5kHz

- Power factor p.f.=0.85

- Modulation index m=1

- Junction temperature TJ=125°C

There are two possibilities for utilizing the performance of new X-Series power modules. One possibility is a reduction of the IGBT module power losses. The power losses decrease by about 10% compared to the H-Series. The other possibility is increasing the inverter output current. The output current can be increased by about 25% compared to the H-Series. In addition, 150°C operation of X-series enables to increase even more output current than 125°C operation.

Conclusion

The newly developed 4500V X-Series enables significant increase in the inverter output power. Key enabling factors are an increased maximum junction temperature of 150°C, an improved thermal management and reduced power losses in the module. A large line-up and backward compatibility to H-Series and R-Series ensures a flexible converter design and an easy design-in. Furthermore, two different chip sets (X-type and XA-type) facilitates the optimal operation at required switching frequencies.

References

[1] Mitsubishi Electric Corporation, “Mitsubishi Electric to Expand Lineup of X-Series HVIGBT Modules,” Press Release No. 3094, May 2017

[2] Prof. Dr. M. Hiller, “Leistungselektronik mit Si-Bauelementen für die Mittelspannung”, Tagungsband des 1. Industriearbeitskreis Mittelspannungs-Leistungelektronik [Proceedings of the 1. Industry Working Group Medium-Voltage Power Electronics], Fraunhofer ISE, Berlin, Germany, 2016.

Related posts

Now available – DC/DC converters from PREMIUM

Now available – DC/DC converters from PREMIUM

New release in DACPOL lighting for lathes – Kira covers

New release in DACPOL lighting for lathes – Kira covers

Leave a comment